MarineCityBrian

Apprentice Tinkerer

Aft Led Lines Follow-Up (Progress - Part 2 of 4)

Once I had marked-off all of the hardware, I drilled the holes from the topside either using the hardware itself as a guide or the supplied guides that came with some of the hardware. Then, from beneath (after removing the headliner), I drilled up through the deck with a 1-1/8" hole saw, STOPPING AT THE UPPER LAYER OF GLASS (after my 1st mistake, I took care to clearly mark my hole-saw...more on that later...):

This is the one for the port-side halyard winch which I relocated from the mast:

Next, use a screwdriver to pop-out the deck coring (in the case of my boat it's marine plywood)

Next, use a chisel to get down to the parent glass layer

Nice clean holes! (these are actually the ones for the deck organizer whereas the above are for the port winch)

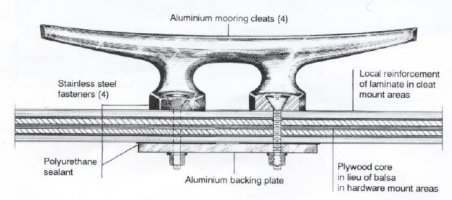

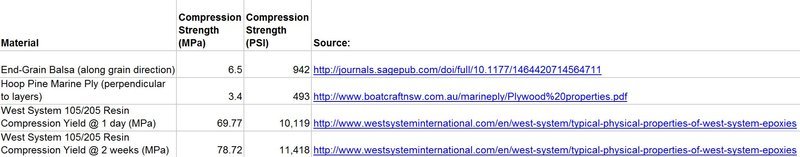

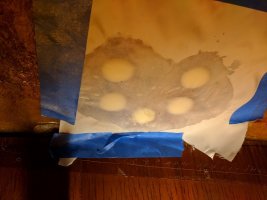

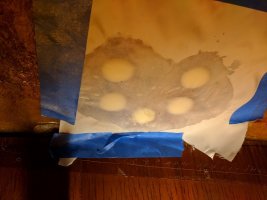

After doing this, I mixed up ~3 pumps of Epoxy Resin and mixed-in 406 filler until I got to a "Peanut Butter" consistency (West Systems defines this as a mix that is thick enough so that when a stirrer is pulled from it the peaks are thick enough to stand-up rather than fall down) such that it could be applied to the underside of the deck. The objective here is to fill these oversized holes with a plug of solid strengthened epoxy to keep the core nice and dry as well as having a material with a higher compressive strength than the plywood it's replacing. I started using the stir-stick as a putty knife and wetting the core as much as possible, then mashing it up into the cavity until it pushed-out through the small hole in the gel-coated top deck layer. I then leveled it flat to the inside core with the stir-stick, if not slightly proud, and finally placed a piece of release fabric over the bottom-side and rolled it several times with a finned roller to remove as many bubbles as possible:

I used a little masking tape just to hold the release fabric up. The release fabric probably isn't mandatory, but it does make a nice smooth surface once released and purportedly eliminates the amine blush that plagues certain epoxies (which would only really be a problem if we were to apply a 2nd layer of epoxy).

Once I had marked-off all of the hardware, I drilled the holes from the topside either using the hardware itself as a guide or the supplied guides that came with some of the hardware. Then, from beneath (after removing the headliner), I drilled up through the deck with a 1-1/8" hole saw, STOPPING AT THE UPPER LAYER OF GLASS (after my 1st mistake, I took care to clearly mark my hole-saw...more on that later...):

This is the one for the port-side halyard winch which I relocated from the mast:

Next, use a screwdriver to pop-out the deck coring (in the case of my boat it's marine plywood)

Next, use a chisel to get down to the parent glass layer

Nice clean holes! (these are actually the ones for the deck organizer whereas the above are for the port winch)

After doing this, I mixed up ~3 pumps of Epoxy Resin and mixed-in 406 filler until I got to a "Peanut Butter" consistency (West Systems defines this as a mix that is thick enough so that when a stirrer is pulled from it the peaks are thick enough to stand-up rather than fall down) such that it could be applied to the underside of the deck. The objective here is to fill these oversized holes with a plug of solid strengthened epoxy to keep the core nice and dry as well as having a material with a higher compressive strength than the plywood it's replacing. I started using the stir-stick as a putty knife and wetting the core as much as possible, then mashing it up into the cavity until it pushed-out through the small hole in the gel-coated top deck layer. I then leveled it flat to the inside core with the stir-stick, if not slightly proud, and finally placed a piece of release fabric over the bottom-side and rolled it several times with a finned roller to remove as many bubbles as possible:

I used a little masking tape just to hold the release fabric up. The release fabric probably isn't mandatory, but it does make a nice smooth surface once released and purportedly eliminates the amine blush that plagues certain epoxies (which would only really be a problem if we were to apply a 2nd layer of epoxy).

Last edited: