Over the 40 year lifespan of our boat, there has been a lot of hardware added, removed, or relocated which leads to holes that need to be filled. The boom is a good example. Multiple lazy jack systems, cleats no longer needed, and the reefing tracks we’re removing, all adding up to over 30 holes in our boom. Here’s how I have been filling them so far:

After removing the hardware, I sanded the spots that were corrode which happened to be at every fastener location.

Then I drilled and tapped a 5/16” hole. I chose 5/16 because that’s the size fastener used on the reefing track and they accounted for most of the holes. I cleaned each hole with acetone and a wire brush / pipe cleaner thing.

I want to avoid future corrosion due to dissimilar metals, so I purchased some threaded 5/16” 6061 aluminum rod that I cut up into small pieces making sure to clean up the threads by backing a nut past the cut point.

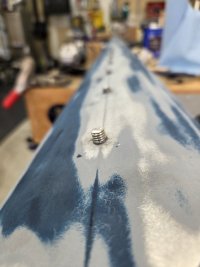

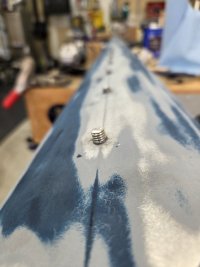

I pre inserted each filler piece to double check the threads then mixed up some JB Weld epoxy. Using a Q-tip, I applied the epoxy to the threaded hole and the filler piece and screwed each one in, so they sat proud of the inside service by apx. 1 thread.

After the epoxy cured, I ground off the filler pieces and sanded them smooth with the rest of the boom.

I don’t think the mast has as many holes to fill, but there are still quite a few. I was finally able to find 6061 screws which will save time by not requiring cutting up the threaded rod.

After removing the hardware, I sanded the spots that were corrode which happened to be at every fastener location.

Then I drilled and tapped a 5/16” hole. I chose 5/16 because that’s the size fastener used on the reefing track and they accounted for most of the holes. I cleaned each hole with acetone and a wire brush / pipe cleaner thing.

I want to avoid future corrosion due to dissimilar metals, so I purchased some threaded 5/16” 6061 aluminum rod that I cut up into small pieces making sure to clean up the threads by backing a nut past the cut point.

I pre inserted each filler piece to double check the threads then mixed up some JB Weld epoxy. Using a Q-tip, I applied the epoxy to the threaded hole and the filler piece and screwed each one in, so they sat proud of the inside service by apx. 1 thread.

After the epoxy cured, I ground off the filler pieces and sanded them smooth with the rest of the boom.

I don’t think the mast has as many holes to fill, but there are still quite a few. I was finally able to find 6061 screws which will save time by not requiring cutting up the threaded rod.