acubria

Member II

I have never unstepped a sail boat before but some experienced friends are helping . We are using the clubs hoist to unstep the mast.

A few questions for 26-2 owners who have done this before:

thank you in advance

A

A few questions for 26-2 owners who have done this before:

- Am I right to assume that the stainless steel plate at the foot of the mast will remain attached to the deck when lifting the mast?

- Once the shrouds and stays are disconnected, will the mask come off the boat just by lifting it ? There are no pins securing the mast to the boat?

- How/when to disconnect electric wires? Are the connections at the foot of the mast (will see connections once the mast lifts a few inches) or inside the cabin somewhere behind the ceiling liner. I don't see access to wires anywhere.

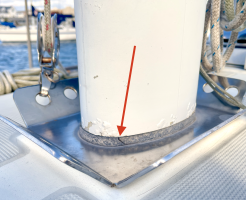

- In the close up image, I see a crack on a metal collar. Do I need to worry about this ? Any experience fixing it?

thank you in advance

A