My boat engine has fuel injectors that squirt diesel fuel into cylinders that are compressed and then combust.

The cylinders are attached to cams that further turn my prop shaft and push the boat.

Do my injectors squirt the same amount of fuel into the cylinders on every rotation, regardless of rpm speed?

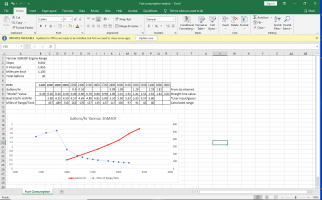

If so, then I think that means one hour of use at 4,000 rpm should burn as much diesel as 2 hours of use at 2,000 rpm, (right?)

This matters a lot in terms of range, if I can get 4kts/hr at 2,000rpm but only 5kts at 4,000rpm (decreasing returns to fuel consumption)

Gracias,

Tom

The cylinders are attached to cams that further turn my prop shaft and push the boat.

Do my injectors squirt the same amount of fuel into the cylinders on every rotation, regardless of rpm speed?

If so, then I think that means one hour of use at 4,000 rpm should burn as much diesel as 2 hours of use at 2,000 rpm, (right?)

This matters a lot in terms of range, if I can get 4kts/hr at 2,000rpm but only 5kts at 4,000rpm (decreasing returns to fuel consumption)

Gracias,

Tom