Just installed a new Whale Gusher manual bilge pump and a new 1.5" bilge hose to serve it. The original aluminum pump never worked since I got the boat, and I could see no use in rebuilding a pump that corrodes in salt water. I also couldn't stomach re-using the original, 40 y/o corrugated 1.5" bilge hose that was attached to the pump and running under the TAFG.

First, removing the old hose was a bit of a hassle. I had read speculation that the hose is zip-tied to the TAFG liner and is almost non-removable, but I found this wasn't the case. The difficulty in removing mine came from the hose corrugations snagging on the edge of the very small TAFG-liner exit hole and the sharp 90 bend the hose made to exit the liner. Once worked past this snag point, the hose pulled out easily. After the hose was out, I cut a larger exit slot in the TAFG liner using hole and oscillating saws.

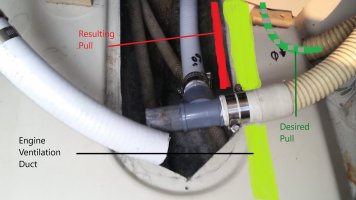

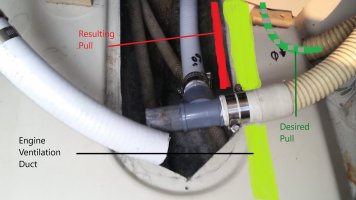

The process of pulling the new was probably the hardest part. I borrowed an idea I saw here about slitting/collapsing the leading edge of the hose to help it pull through. Then I tensioned the pull-rope while pushing the new hose up through the bilge access area. Despite the pull rope having the same routing as the original hose, both times I pulled the hose through it wound up on the wrong of the engine ventilation duct (i.e., alongside the rudder post rather than under the starboard-ish exit slot).

By the third try, I decided to feed the hose in the other direction, starting at the stern, and pulling towards the bilge pocket. The third time was finally a success.

Installation of the new pump was more straightforward. As others have mentioned, Whale changed the mounting hole pattern, so I had to drill 6 new mounting holes and seal off the original holes (most of which end up hidden behind the pump cover-plate).

I still need to run the exit-line hose and make the final connections. While I'm working under there, the corrugated hoses for the scuppers will get replaced too. Surprisingly, I haven't seen any cracks/splits in the old hose I've removed. It's all very stiff however, and there's no doubt it's overdue for replacement.

First, removing the old hose was a bit of a hassle. I had read speculation that the hose is zip-tied to the TAFG liner and is almost non-removable, but I found this wasn't the case. The difficulty in removing mine came from the hose corrugations snagging on the edge of the very small TAFG-liner exit hole and the sharp 90 bend the hose made to exit the liner. Once worked past this snag point, the hose pulled out easily. After the hose was out, I cut a larger exit slot in the TAFG liner using hole and oscillating saws.

The process of pulling the new was probably the hardest part. I borrowed an idea I saw here about slitting/collapsing the leading edge of the hose to help it pull through. Then I tensioned the pull-rope while pushing the new hose up through the bilge access area. Despite the pull rope having the same routing as the original hose, both times I pulled the hose through it wound up on the wrong of the engine ventilation duct (i.e., alongside the rudder post rather than under the starboard-ish exit slot).

By the third try, I decided to feed the hose in the other direction, starting at the stern, and pulling towards the bilge pocket. The third time was finally a success.

Installation of the new pump was more straightforward. As others have mentioned, Whale changed the mounting hole pattern, so I had to drill 6 new mounting holes and seal off the original holes (most of which end up hidden behind the pump cover-plate).

I still need to run the exit-line hose and make the final connections. While I'm working under there, the corrugated hoses for the scuppers will get replaced too. Surprisingly, I haven't seen any cracks/splits in the old hose I've removed. It's all very stiff however, and there's no doubt it's overdue for replacement.

Last edited: