EricFox

Member II

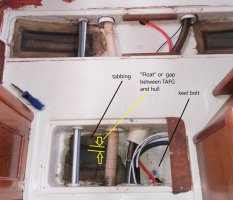

I bought my E38 last spring and have had a great time sailing her this summer. When I bought it I knew that there were some issues with the keel/hull seam at the back of the keel going back 5+ years. A flexible sealant had been used on the hull to in an attempt to seal that seam at the back (~18" long). The surveyor wasn't concerned - he suggested to sail it over the summer, then to pull out as much of the sealant as I could once back on the hard to let it dry out over the winter, then repair the seam next spring. Below are a few pics of what was under the sealant - a bigger gap than I was anticipating. The rest of the keel/hull joint looks good.

Seeing that, I went to remove the but on the rear keel bolt to see what was there. There was zero torque on the nut. There were 4 washers under it, and then flexible black sealant down into the hole. There was nothing solid for the nut to seat on hence the lack of any torque. When I dug out the sealant, I saw what appear to be missing chunks of fiberglass at the bottom of that bilge compartment that had been filled with sealant. That appears to be where the standing water around the bolt was coming from. I also found significant corrosion on the bolt where the washers were.

I'll head back next week to investigate that sub-bilge area more closely - where are the access points within the boat for water to enter that void, what does it look like in there with a borescope, etc. I will also take off the nut on the keel bolt immediately ahead of the rear bolt to look for any signs of corrosion (didn't have the right socket last weekend).

Re: the bad bolt, my current plan (after having read almost every post on keel bolts) is to do the following in spring: 1) have a local machinest make a sleeve to make up for the corroded section of the bolt, then build up a resin/glass seat around the sleave for a fastener to seat on; or 2) simply fill the rear keel bolt hold with resin. The first option still allows me to drop the keel down the road - the second would make that a bit more difficult.

Re: the outside work, my plan is to fill the gaps with sealant (4200? 5200? other?) as best I can, then fill the seam either with glass + fairing compound, or used G/Flex epoxy.

My only real concern now is the status of the other keel bolts in areas that I won't be able to see. There is externally or internally to suggest a problem. Given that, I'm reluctant to drop the keel right away. But I don't know how easy it is for water to migrate along the keel/hull joint from the rear of the keel where there is an obvious route for water ingress forward to other keel bolts. The sealant in the gap looks to be holding, but that might not be meaningful. Is it likely that water would make its way forward?

For those familiar with the grid for the E38, is that sub-bilge void supposed to be sealed, or there access points within the main bilge that could feed that area with water? Also, from other posts, it looks like I'm not the only one who has discovered that the nut on the real keel bolt has nothing firm to seat on - does that make sense?

One final question, does anyone know the approximate length of the rear keel bolt? I have seen a picture in one post that makes it look like it might be 6 to 8 inches long.

By the way, for context, the boat is only used in the Great Lakes. It saw some ocean use 25 years ago, but none since. And looking at pictures the previous owner took when he bought it in 2018, I'm pretty sure this damage was all there then.

Any advice most appreciated! Thanks.

Eric

Seeing that, I went to remove the but on the rear keel bolt to see what was there. There was zero torque on the nut. There were 4 washers under it, and then flexible black sealant down into the hole. There was nothing solid for the nut to seat on hence the lack of any torque. When I dug out the sealant, I saw what appear to be missing chunks of fiberglass at the bottom of that bilge compartment that had been filled with sealant. That appears to be where the standing water around the bolt was coming from. I also found significant corrosion on the bolt where the washers were.

I'll head back next week to investigate that sub-bilge area more closely - where are the access points within the boat for water to enter that void, what does it look like in there with a borescope, etc. I will also take off the nut on the keel bolt immediately ahead of the rear bolt to look for any signs of corrosion (didn't have the right socket last weekend).

Re: the bad bolt, my current plan (after having read almost every post on keel bolts) is to do the following in spring: 1) have a local machinest make a sleeve to make up for the corroded section of the bolt, then build up a resin/glass seat around the sleave for a fastener to seat on; or 2) simply fill the rear keel bolt hold with resin. The first option still allows me to drop the keel down the road - the second would make that a bit more difficult.

Re: the outside work, my plan is to fill the gaps with sealant (4200? 5200? other?) as best I can, then fill the seam either with glass + fairing compound, or used G/Flex epoxy.

My only real concern now is the status of the other keel bolts in areas that I won't be able to see. There is externally or internally to suggest a problem. Given that, I'm reluctant to drop the keel right away. But I don't know how easy it is for water to migrate along the keel/hull joint from the rear of the keel where there is an obvious route for water ingress forward to other keel bolts. The sealant in the gap looks to be holding, but that might not be meaningful. Is it likely that water would make its way forward?

For those familiar with the grid for the E38, is that sub-bilge void supposed to be sealed, or there access points within the main bilge that could feed that area with water? Also, from other posts, it looks like I'm not the only one who has discovered that the nut on the real keel bolt has nothing firm to seat on - does that make sense?

One final question, does anyone know the approximate length of the rear keel bolt? I have seen a picture in one post that makes it look like it might be 6 to 8 inches long.

By the way, for context, the boat is only used in the Great Lakes. It saw some ocean use 25 years ago, but none since. And looking at pictures the previous owner took when he bought it in 2018, I'm pretty sure this damage was all there then.

Any advice most appreciated! Thanks.

Eric