You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rudder post grease - E26

- Thread starter NW26

- Start date

I just pump till no more grease will go in. My 32-3 once took three full 3 oz. cannisters, but it had a big void after years of neglect. My current boat only admits a little grease, after which no more can be forced in.

To my mind, any good lube works for the chain and the quadrant box sheaves.

To my mind, any good lube works for the chain and the quadrant box sheaves.

Jerry VB

E32-3 / M-25XP

There should also be a zerk on the upper bearing between the steering quadrant and the floor of the cockpit. That is important to grease too - keeps the steering low friction and prevents the upper bearing from wearing out. Finding it and getting a grease gun on it will be a bit of a challenge.

On my E32-3, I found it after folding myself in thirds and spelunking in the aft (port side) lazerette. Once I got in there, I was able to see it. I was not able to touch it, but the (full size) grease gun hose was able to reach between the quadrant and the cockpit floor. Unfortunately, the zerk was totally rusted internally so I could not force grease into it. Fortunately I was able to unscrew it with a socket on a couple of extensions and screw in a replacement the same way. I put a little tape in the socket to hold the new zerk by friction and then spun it until I got lucky.

After greasing the upper bearing, my steering was noticeably smoother.

On my E32-3, I found it after folding myself in thirds and spelunking in the aft (port side) lazerette. Once I got in there, I was able to see it. I was not able to touch it, but the (full size) grease gun hose was able to reach between the quadrant and the cockpit floor. Unfortunately, the zerk was totally rusted internally so I could not force grease into it. Fortunately I was able to unscrew it with a socket on a couple of extensions and screw in a replacement the same way. I put a little tape in the socket to hold the new zerk by friction and then spun it until I got lucky.

After greasing the upper bearing, my steering was noticeably smoother.

I don't think I had a top Zerk on my 32-3. I used to ladle grease on where the post is visible in the top bearing, and it seemed to me it worked its way down into the bushing. You can see the post turn as you wiggle the wheel, and the grease likely finds its way.

By the way, those four Phillips machine screws hold the top bushing in place. If (with the top plate off) the rudder post is seen to move around visibly when sailing, , or clunks when you tack, the nuts on the machine screws* may have fallen off under the cockpit. That leaves the bushing assembly loose, which lets the post flop around. You can't identify a loose bushing from this static view, since the flange is imbedded in the deck and cannot wobble.

That's harder to explain than to see. You have to be sailing, and take the plate off, to see the rudder post wobble. It's not under side pressure at the dock.

Alternatively you can crawl under the cockpit and check the nuts, which is a contortion on that particular boat.

*The nuts on the machine screws, and the underdeck bushing, are visible in Jerry's photo in the next post.

By the way, those four Phillips machine screws hold the top bushing in place. If (with the top plate off) the rudder post is seen to move around visibly when sailing, , or clunks when you tack, the nuts on the machine screws* may have fallen off under the cockpit. That leaves the bushing assembly loose, which lets the post flop around. You can't identify a loose bushing from this static view, since the flange is imbedded in the deck and cannot wobble.

That's harder to explain than to see. You have to be sailing, and take the plate off, to see the rudder post wobble. It's not under side pressure at the dock.

Alternatively you can crawl under the cockpit and check the nuts, which is a contortion on that particular boat.

*The nuts on the machine screws, and the underdeck bushing, are visible in Jerry's photo in the next post.

Last edited:

Jerry VB

E32-3 / M-25XP

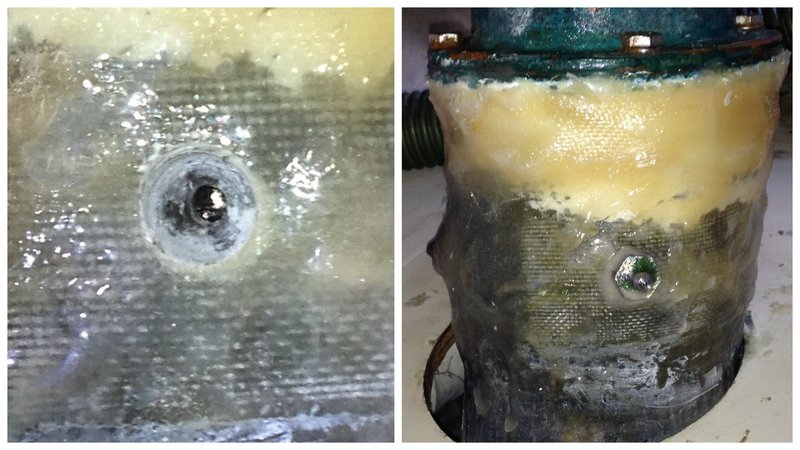

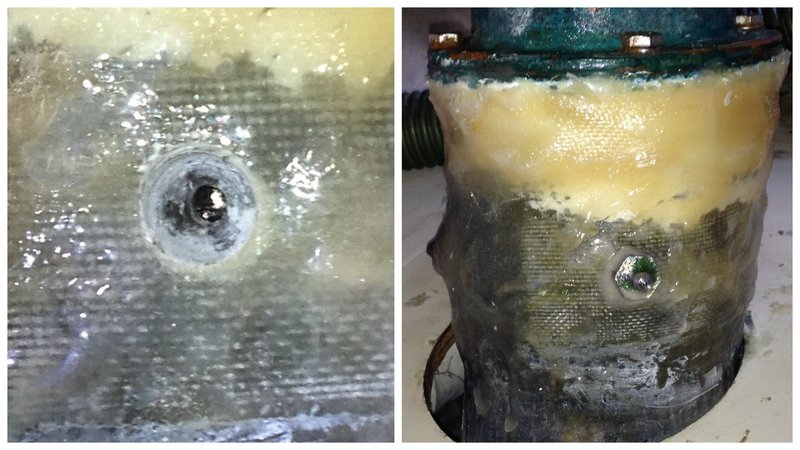

Picture of the upper zerk on the E32-3 rudder post. This was taken from the aft lazerette so the picture is looking forward and the zerk points to port. It is essentially impossible to see by looking in the lazerette without actually getting into it. Once you get in, it is clearly visible and relatively easy to grease. I greased mine liberally (once I replaced the rusted shut zerk). After pumping a bunch of grease blindly, I found the grease squeezed out below the zerk. I cleaned it off as best I could using a paper towel on a screwdriver.

Jerry VB

E32-3 / M-25XP

I bought a blister pack of fittings (various angles) from the local hardware store. The pack is still on board so I cannot verify it, but they should be 1/4"-28. The hardware store zerks are likely plated steel but I'm in fresh water and the zerk should stay dry so rust is not a major issue for me. If I get ambitious, I might swap my zerks out for stainless but probably not.what size zerk fitting does this take?

Accessibility without removing the quadrant is strictly via sockets with about 10" of extensions. No room for fingers or vice-grips. You should be able to spray it with a penetratingly oil (Kroil, PB Blaster, etc.) - most of them shoot a pretty good stream. Here's to hoping you get lucky with your zerk and it comes out without a fight.

Addendum: If you cannot get the zerk off, I would use @Christian Williams technique of greasing it from the top via the access plate. Lubricating the bearing is important. My steering force was not excessive but it went down noticeably after greasing.

Last edited:

Re grease fitting size: When I installed a Zerk I went to a larger size, and stainless steel. Just seemed more appropriate. Internet source nowadays, cheap. May need a size-compatible hose on the grease gun.

"I picked up a new half-inch stainless Zerk fitting with a quarter-inch inlet from a boatyard parts department. I drilled a half inch hole in the side of the rudder tube as deep as the Zerk threads. This didn't penetrate through tube to post. I drilled further with a quarter-inch bit, carefully probing. When I thought I was all the way through it was out of the slip again, full speed ahead again, down into the after berth again--and indeed water was squirting out of the new Zerk hole, proof of an open path to the inside of the tube.

I glued the new Zerk in with thickened epoxy and when it cured pumped in three 3-ounce tubes of marine grease through the new nipple."

From blog entry here.

"I picked up a new half-inch stainless Zerk fitting with a quarter-inch inlet from a boatyard parts department. I drilled a half inch hole in the side of the rudder tube as deep as the Zerk threads. This didn't penetrate through tube to post. I drilled further with a quarter-inch bit, carefully probing. When I thought I was all the way through it was out of the slip again, full speed ahead again, down into the after berth again--and indeed water was squirting out of the new Zerk hole, proof of an open path to the inside of the tube.

I glued the new Zerk in with thickened epoxy and when it cured pumped in three 3-ounce tubes of marine grease through the new nipple."

From blog entry here.

bsangs

E35-3 - New Jersey

I don't think I had a top Zerk on my 32-3. I used to ladle grease on where the post is visible in the top bearing, and it seemed to me it worked its way down into the bushing. You can see the post turn as you wiggle the wheel, and the grease likely finds its way.

View attachment 44095

Apologies for reviving this post, but I'm piggybacking on my upper zerk issue from another thread, and maybe this is the answer instead. So just dump some grease around this post from above, and it'll find its way down? You did this without issue?

Glad you did revive it, I had a zerk question myself and was glad it pulled up Christian‘s post on adding one to the glassed post housing. I’m not getting grease into my zerks and I think they’re either seized or ??? Gonna give it another shot with some tri flow and a punch to see if I can knock the balls loose but if not it’ll be replacement.

Alan Gomes

Sustaining Partner

Referring back to the original question from last year, as well as the subject line of this thread: That sure doesn't look like my E26 in the picture you posted. I'm not simply talking about the presence of a quadrant for wheel steering, but the rest of it. What year is your boat?

Anyway, on my E26 I do have a zerk fitting on the upper rudder post bearing, i.e., the flange that bolts to the cockpit floor, from which the rudder post protrudes and attaches to my tiller. Regardless, I never use it anyway. When I do my haulouts I (sometimes) just drop the rudder, grease it with Teflon grease (SuperLube), and reinstall. That's easily good for a couple or three years, anyway.

Of course, you've got more stuff to disassemble to drop the rudder than I do, so the calculus may be different for wheel steering. Plus, I'm not sure whether some of the larger Ericsons might require digging a hole to drop the rudder into in order to make the rudder post clear the hull.

Anyway, on my E26 I do have a zerk fitting on the upper rudder post bearing, i.e., the flange that bolts to the cockpit floor, from which the rudder post protrudes and attaches to my tiller. Regardless, I never use it anyway. When I do my haulouts I (sometimes) just drop the rudder, grease it with Teflon grease (SuperLube), and reinstall. That's easily good for a couple or three years, anyway.

Of course, you've got more stuff to disassemble to drop the rudder than I do, so the calculus may be different for wheel steering. Plus, I'm not sure whether some of the larger Ericsons might require digging a hole to drop the rudder into in order to make the rudder post clear the hull.

I had a similar issue on my 1984 E35 III. A little heat from a hair dryer was enough to loosen up the old grease and allow the new grease to flow in.Glad you did revive it, I had a zerk question myself and was glad it pulled up Christian‘s post on adding one to the glassed post housing. I’m not getting grease into my zerks and I think they’re either seized or ??? Gonna give it another shot with some tri flow and a punch to see if I can knock the balls loose but if not it’ll be replacement.

Apologies for reviving this post

For the record, reviving an old thread with a new addition is preferred because it keeps the information together and therefore appreciated by all.

For the record, reviving an old thread with a new addition is preferred because it keeps the information together and therefore appreciated by all.

This is great timing for me too. After seeing this thread last evening, I visited the boat today ('89 E34-2) and disassembled some divider walls in the aft locker to get access to the rudder post. I wanted to try filling it up with grease. I dove headfirst and only found one zerk, maybe 1/3 of the distance below the flange, and pumped there (see attached photo). It does seem like the zerk would be further down closer to the lower bushing. Am I missing something?

I could not find a zerk above the quadrant, and if I did find one with my borescope, I'm wondering if I'd be able to get in there to grease it.

Does anyone know if the top zerk is accessible from the locker and on the aft side of the assembly, or is it actually on the front and accessed from the berth?

Otherwise, I'm certainly going to try Christian's approach of packing grease around the top of the post from the cockpit access plate.

I could not find a zerk above the quadrant, and if I did find one with my borescope, I'm wondering if I'd be able to get in there to grease it.

Does anyone know if the top zerk is accessible from the locker and on the aft side of the assembly, or is it actually on the front and accessed from the berth?

Otherwise, I'm certainly going to try Christian's approach of packing grease around the top of the post from the cockpit access plate.

Attachments

It does seem like the zerk would be further down

The idea seems to be that the grease packs the void between the tube and the rudder post, and helps seal the gland on top, in addition to lubricating the bronze bushing on which the rudder post turns.

The Ericson zerk always appears to be placed somewhere low, or even near the middle, of the rudder tube. Nobody has reported a grease fitting installed into the bronze bushing itself, which tends to be buried in the layup.

The idea seems to be that the grease packs the void between the tube and the rudder post, and helps seal the gland on top, in addition to lubricating the bronze bushing on which the rudder post turns.

The Ericson zerk always appears to be placed somewhere low, or even near the middle, of the rudder tube. Nobody has reported a grease fitting installed into the bronze bushing itself, which tends to be buried in the layup.

Alan Gomes

Sustaining Partner

I have a zerk fitting on the bronze bushing bolted to the cockpit sole. No zerks on the tube itself.It does seem like the zerk would be further down

The idea seems to be that the grease packs the void between the tube and the rudder post, and helps seal the gland on top, in addition to lubricating the bronze bushing on which the rudder post turns.

The Ericson zerk always appears to be placed somewhere low, or even near the middle, of the rudder tube. Nobody has reported a grease fitting installed into the bronze bushing itself, which tends to be buried in the layup.

Yes, that appears to be standard on the top bushing, although I don't think my 32-3 had one (or maybe it was just inaccessible).

I mean the lower bronze bushing.

I mean the lower bronze bushing.

Alan Gomes

Sustaining Partner

Got it.Yes, that appears to be standard on the top bushing, although I don't think my 32-3 had one (or maybe it was just inaccessible).

I mean the lower bronze bushing.

The E26 has no lower bushing of any kind, so it's obviously different from some of (all?) the larger boats in that respect.

I have this same fitting above deck. However, mine also has a zerk fitting about halfway down the tube down in the tiny space under the cockpit. It's all fiberglassed in, so not easy to change out. I should have replaced it during my last haulout, but ran out of time. It is frozen closed, so no hope of using it, either. I looked, but cannot find a picture. I'll take one next time I go out.I have a zerk fitting on the bronze bushing bolted to the cockpit sole. No zerks on the tube itself.

Alan Gomes

Sustaining Partner

I should take a closer look, just out of curiosity. I've been back there and inspected the rudder tube and didn't see it, but perhaps there is one. Doubt I'd bother using it, though.I have this same fitting above deck. However, mine also has a zerk fitting about halfway down the tube down in the tiny space under the cockpit. It's all fiberglassed in, so not easy to change out. I should have replaced it during my last haulout, but ran out of time. It is frozen closed, so no hope of using it, either. I looked, but cannot find a picture. I'll take one next time I go out.