Prairie Schooner

Jeff & Donna, E35-3 purchased 7/21

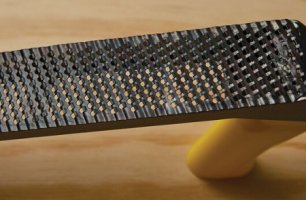

Ditto everything Ray (Pete the Cat) said, above. I found the following long board very helpful. I'd locate and rough down the high spots with it, then move to a power sander.We glassed all the deeper blisters where we had ground beyond the chop layer. Some of those covered a relatively big area. We finished that part a while ago. Now it about how to get the final layers of fairing on most efficiently and deciding how much fairing is enough. I don't think we are there yet.

I had visions of a perfectly fair surface. Before I reached perfection my 66 year old arms ran out. Fatigue determined how far I carried it as much as desired finish. If I were going to do an entire boat bottom, I'd look into a pneumatic long board.

I liked Total Boat fairing compound. It adhered really well and sanded quickly.

It's a long, exhausting job. Keep moving the rock forward. Good luck.

Jeff