I don't quite get what the purpose of trying to align an engine would be with the cutless bearing out of the boat.

I'm not trying to "align" just get the rough stuff dialed it. It all depends on what you have for tools. New cutlass bearings fit the shaft so tight that you often can't tell how it is passing though. Compound to that side loading of a stuffing box and it can make centering and alignment issues quite time consuming. I own a tool that allows me to pres out cutlass bearings and press them in over an in-place shaft. When doing shafting work on the hard, especially things like motor mounts, bolting the shaft up to the engine with the cutlass not in place allows you to roughly dial in the side to side very, very easily. I always find the rough side to side is the most difficult because the motor needs to move and also the mounts can't be stressed or cocked once moved. Up & down is a no brainer. On longer shafts you'll get some sag but not a whole lot on shorter ones. So you can somewhat roughly center top to bottom if you know the shaft sag ahead of time. I have some long shafts kicking around the shop and will measure sag of a known length to know roughly what to expect.

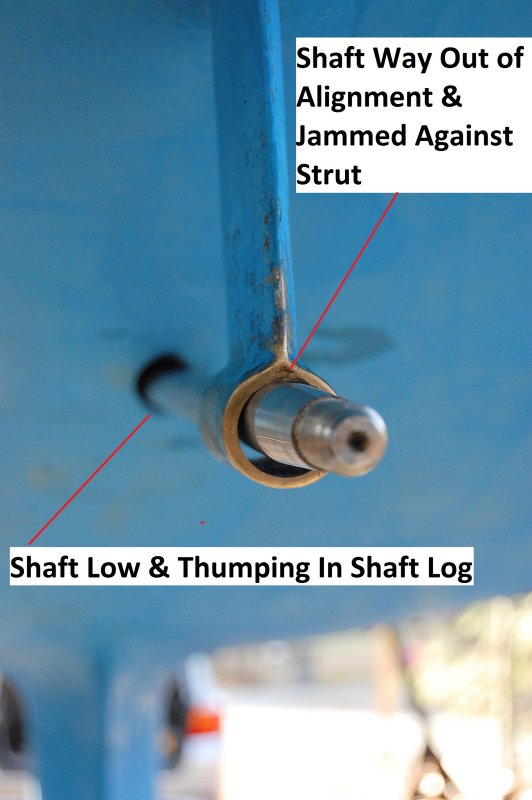

With the tool I own I can press out a cutlass on a boat that is spot on (on the hard) and the shaft is in pretty much the center of the strut side to side. When they're out of alignment you can really see how bad it is...

On boats like the one below you can visibly see how bad the alignment was. This shaft was pinched up quite tightly to the strut once the cutlass was pressed out. If anything it should sag slightly not be pinched up tight to the top of the strut. It was also nearly resting on the shaft log.. These types of gross misalignment's on this boat have nothing to do with in-water or out.

When I do this these are rough baseline adjustments. The final tweaks on the hard are done with the packing gland and cutlass in place then adjusted after a few weeks in the water, and properly tuned.

As to the vibration issues there are some boats that you just won't entirely get rid of them. Many of the M-25's and other three cyl engines get "spots" where they vibrate more than another RPM. The one on our C-36 was 1850 - 1900 RPM. Also the Bushings Inc. mounts used on many of the three point systems really suck as mounts go and transfer every little thing right to the boat.

Last winter I did an 87 E-34. Everything was new. New AQ22 shaft trued to .002" (better than ABYC spec), new flange fitted and faced, brand new Flex-O-Fold two blade prop lap fit to the shaft for better than 95% final fit, not checking prop to shaft fit can often be a cause of prop induced vibrations. The Flex-O-Folds tend to fit shaft tapers pretty poorly.

This was a brand new Flex-O-fold fit to a brand new shaft with a proper & tested ABYC spec shaft taper. The area wiped clean of the prussian blue was the ONLY place it was fitting the shaft. Even with the prop nut tight that is about a 20% fit... Shaft to prop fit should not be over looked when trying to eliminate vibrations.

She also got brand new mounts, new stuffing box hose, new packing, new cutlass bearing.

Once in the water and tuned it was aligned to .002" - .003". The shaft exhibited no wobble and the stuffing box was dead nuts still. While the boat was significantly smoother than it had been you could physically watch the engine get "rolling" when under load. This caused some cyclic vibrations transferred through the hull. A whoooom............. whooooom............whoooooom that you can physically watch occurring. These same engines on four mounts don't exhibit this "rolling" cyclic vibration. Even the four cylinder Westerbekes on some Sabre's will do the same thing with the three point mount so it's not just the difference between three and four cylinder engines.

Sometimes no matter how perfect everything is these boats can they can still exhibit some vibrations that may not be associated with the shaft, prop, cutlass or alignment. Also two blade props are just not as smooth as a three. Prop shops using the Hale MRI or Prop Scan tools can drastically cut two blade prop vibrations but it will still not be as smooth as a good three blade.