-

Untitled Document The 2024-2025 Fund Raising Season has Opened!

EricsonYachts.org has opened the season for raising funds to support the expenses of the site. If you would like to participate, please see the link below for additional information.

Thanks so much for your continued support of EricsonYachts.org!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Struggling to find the problem - air within fuel system?

- Thread starter patrscoe

- Start date

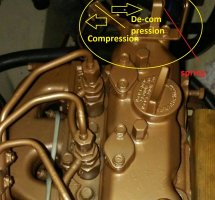

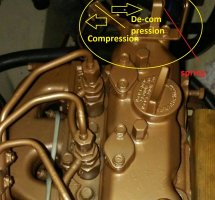

In case it helps anyone, I took photos of the M-25's decompression lever, and tested starting and running my engine in two lever positions. These pics are from aft, looking forward (actually, it's my 'spare' engine in my garage)

- lever at 90 degrees (3 o'clock) position - fixed position

- lever at 45 degrees (1:30 o'clock) position - floating position

- lever lifted to vertical position against the spring tension - decompression position

My engine starts and runs normally in either the fixed or floating position - no noticeable difference in my observations

** Do not try to lift the lever to the 'decompression' position while the engine is running - one immediately feels a rapid bumping sensation through the lever.

I didn't try to turn my engine over in the decompressed position. The bit of string that's still on my spare engine's lever gives a clue to how one might turn over the engine from the start button in the cockpit if you don't have a helper by the engine.

- lever at 90 degrees (3 o'clock) position - fixed position

- lever at 45 degrees (1:30 o'clock) position - floating position

- lever lifted to vertical position against the spring tension - decompression position

My engine starts and runs normally in either the fixed or floating position - no noticeable difference in my observations

** Do not try to lift the lever to the 'decompression' position while the engine is running - one immediately feels a rapid bumping sensation through the lever.

I didn't try to turn my engine over in the decompressed position. The bit of string that's still on my spare engine's lever gives a clue to how one might turn over the engine from the start button in the cockpit if you don't have a helper by the engine.

When I was chasing down my air leaks (OP), I also investigated the decompression lever. Mine also started in the fixed and 'floating' position but the decompression is when you push it all the way over under spring tension. But I remember there was a different sound of the engine when it was in the floating position and I am assuming, if under loadand higher RPMs, the engine would not have provided the power you normally would get in that float position. I didn't want to test that method.

I'm not sure how you get the lever into the position shown in the first picture. Mine doesn't go that way (at least, I've never tried to push it over that far). Here is the normal (compression) position on mine:

I've cranked my engine with the lever in the "decompress" position. It sounds just like the starter motor cranking when the solenoid/pinion gear isn't engaging the engine.

I've cranked my engine with the lever in the "decompress" position. It sounds just like the starter motor cranking when the solenoid/pinion gear isn't engaging the engine.

Last edited:

Looking at the rear of the engine in photo 2, I am wondering how you get to the fill plug/dip stick on the top of the Hurth? (Or am I looking at it incorrectly?)

Yes Loren, you have it correct.Looking at the rear of the engine in photo 2, I am wondering how you get to the fill plug/dip stick on the top of the Hurth? (Or am I looking at it incorrectly?)

I forget which "hole" I pull it through, but I can push it upward from the transmission with one hand and the grab the top of the dip stick with the other hand.