One of the benefits of DIY boat projects is discovering new things about your boat. I've made several trips up the mast the last few months as I'm changing out the masthead sheaves and standing rigging.

A while back, I discovered these, and didn't know what they were.

Turns out they're T-Terminal plugs, designed to plug the remaining opening in the T-Terminal after the rigging has been installed.

(shroud T-fittings)

(shroud T-fittings)

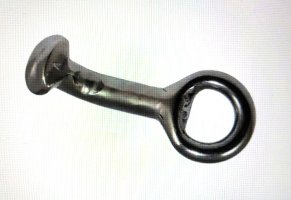

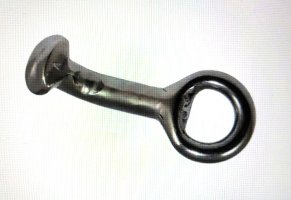

This set of T-Terminals (first photo) sits about 2' above the upper spreaders, is angled backwards slightly, and is a smaller diameter than those used to hold the shrouds. I asked a guy at the rigging shop about them, and he had no doubt at all that they're for a check stay, to be used with a fitting like this:

I guess the thought is that since the check stay isn't always tensioned, the rubber plug is needed to keep the T-fitting from slipping out of the T-terminal.

Though none of my shroud T-Terminals had these plugs (shrouds are always under tension, so there's no way the shroud fitting will turn itself sideways and come loose from the terminal) I decided to plug all the shroud terminals anyway, with the thought that it might reduce the amount of water that enters the mast. With 10 T-terminals (2ea for uppers, mids, fwd lowers, aft lowers, and check stays), that's about 2.5 sq inches of open holes on the sides of the mast (though, many of these are "hidden" somewhat under the shadow of the spreaders.

The plugs are made by Hayn, with part number HAY SHRPM07 (6-7mm plug, for the shroud terminals), and HAY SHRPM04 (4mm plug, for the check stay terminals). Apparently, these also go by the name "Gibb Plugs." You can see the name "Gibb" stamped on the side of the check-stay plug in the first photo above. The plugs run about $7.50 ea at Fisheries Supply.

theriggingco.com

theriggingco.com

While we're at it at, anyone here use a check-stay on their Bruce King E32/35/38? From what I've read, they reduce mast pumping when sailing upwind. Seems I sometimes read about the E36RH guys using running backstays. Is this a similar concept?

A while back, I discovered these, and didn't know what they were.

Turns out they're T-Terminal plugs, designed to plug the remaining opening in the T-Terminal after the rigging has been installed.

(shroud T-fittings)

(shroud T-fittings)This set of T-Terminals (first photo) sits about 2' above the upper spreaders, is angled backwards slightly, and is a smaller diameter than those used to hold the shrouds. I asked a guy at the rigging shop about them, and he had no doubt at all that they're for a check stay, to be used with a fitting like this:

I guess the thought is that since the check stay isn't always tensioned, the rubber plug is needed to keep the T-fitting from slipping out of the T-terminal.

Though none of my shroud T-Terminals had these plugs (shrouds are always under tension, so there's no way the shroud fitting will turn itself sideways and come loose from the terminal) I decided to plug all the shroud terminals anyway, with the thought that it might reduce the amount of water that enters the mast. With 10 T-terminals (2ea for uppers, mids, fwd lowers, aft lowers, and check stays), that's about 2.5 sq inches of open holes on the sides of the mast (though, many of these are "hidden" somewhat under the shadow of the spreaders.

The plugs are made by Hayn, with part number HAY SHRPM07 (6-7mm plug, for the shroud terminals), and HAY SHRPM04 (4mm plug, for the check stay terminals). Apparently, these also go by the name "Gibb Plugs." You can see the name "Gibb" stamped on the side of the check-stay plug in the first photo above. The plugs run about $7.50 ea at Fisheries Supply.

Hayn Marine "T" Terminal Backing Plate Rubber Plugs - The Rigging Company

T termainal plub gibb plug

theriggingco.com

theriggingco.com

While we're at it at, anyone here use a check-stay on their Bruce King E32/35/38? From what I've read, they reduce mast pumping when sailing upwind. Seems I sometimes read about the E36RH guys using running backstays. Is this a similar concept?

Last edited: