Screwing in the inner frames provides enough compression for butyl. (I found some weird problem with getting them to screw back in evenly that I never fully figured out.) I still have one port that's still "temporarily" sealed with butyl (I forgot that one.) Still doing good. One of the larger ports had been re-sealed with butyl at some point in the past, and it did not seem to be one of the leakers, even though the remaining butyl was pretty old and dried up.

Guest viewing is limited

- You have a limited number of page views remaining

- 21 guest views remaining

- Register now to remove this limitation

-

Untitled Document Join us on March 28th, 7pm EDT

for the CBEC Virtual Meeting

EY.o March Zoom Meeting

All EYO members and followers are welcome to join the fun and get to know the people you've met online!

See the link below for login credentials and join us!

(dismiss this notice by hitting 'X', upper right)

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tips for removing original portlights

- Thread starter adam

- Start date

The interior decorative frames hold the portlight in, so butyl works. Its characteristics are just probably not best for this application, because 4200 fills gaps and with painter's tape on the outside makes easy cleanup. And doesn't ooze over time. But I've done it that way.

It is comforting to note that there is no outward force on a portlight at all. The flange is what keeps a thousand pounds of breaking wave from breaking in.

It is comforting to note that there is no outward force on a portlight at all. The flange is what keeps a thousand pounds of breaking wave from breaking in.

I did the ports on my previous boat with butyl as have several boat buddies, works well as long as the exterior frames are reasonably true and fit to the fiberglass without any serious dings or dents and as long as the interior screws engage properly and draw the exterior frame inwards and maintain compression. Yes there is a bit of oozing out for a short time but clean up with a razor blade and mineral spirits is super easy. Also as mentioned, future removal is very easy. To each their own on this one!

There are many butyl formulations, don't use big box (plumbing) stuff... the product from mainesail has great reviews.

There are many butyl formulations, don't use big box (plumbing) stuff... the product from mainesail has great reviews.

Thanks for the info. I'll try butyl tape, and the great thing about it is that if it leaks, I can pull out the portlight, clean it up in 10 minutes, and reseal it with 4200.

That was my reasoning too. By the time the glazing was all finished, the weather had deteriorated too much to use liquid sealant. So I stuck everything back in "temporarily" with butyl tape.

Learning Curve

<style> <!-- /* Font Definitions */ @font-face {font-family:"Cambria Math"; panose-1:2 4 5 3 5 4 6 3 2 4; mso-font-charset:1; mso-generic-font-family:roman; mso-font-format ther; mso-font-pitch:variable; mso-font-signature:0 0 0 0 0 0;} @font-face {font-family:Calibri; panose-1:2 15 5 2 2 2 4 3 2 4; mso-font-charset:0; mso-generic-font-family:auto; mso-font-pitch:variable; mso-font-signature:-536870145 1073786111 1 0 415 0;} /* Style Definitions */ p.MsoNormal, li.MsoNormal, div.MsoNormal {mso-style-unhide:no; mso-style-qformat:yes; mso-style-parent:""; margin:0in; margin-bottom:.0001pt; mso-pagination:widow-orphan; font-size:12.0pt; font-family:Calibri; mso-ascii-font-family:Calibri; mso-ascii-theme-font:minor-latin; mso-fareast-font-family:Calibri; mso-fareast-theme-font:minor-latin; mso-hansi-font-family:Calibri; mso-hansi-theme-font:minor-latin; mso-bidi-font-family:"Times New Roman"; mso-bidi-theme-font:minor-bidi;} .MsoChpDefault {mso-style-type:export-only; mso-default-props:yes; font-family:Calibri; mso-ascii-font-family:Calibri; mso-ascii-theme-font:minor-latin; mso-fareast-font-family:Calibri; mso-fareast-theme-font:minor-latin; mso-hansi-font-family:Calibri; mso-hansi-theme-font:minor-latin; mso-bidi-font-family:"Times New Roman"; mso-bidi-theme-font:minor-bidi;} @page WordSection1 {size:8.5in 11.0in; margin:1.0in 1.0in 1.0in 1.0in; mso-header-margin:.5in; mso-footer-margin:.5in; mso-paper-source:0;} div.WordSection1 {page:WordSection1;} --> </style> [FONT=&]They say the third time is the charm. This is the second time I have rebedded portlights. The first was ok, this time was good, but not great. So hopefully next time I will get it right. [/FONT]

ther; mso-font-pitch:variable; mso-font-signature:0 0 0 0 0 0;} @font-face {font-family:Calibri; panose-1:2 15 5 2 2 2 4 3 2 4; mso-font-charset:0; mso-generic-font-family:auto; mso-font-pitch:variable; mso-font-signature:-536870145 1073786111 1 0 415 0;} /* Style Definitions */ p.MsoNormal, li.MsoNormal, div.MsoNormal {mso-style-unhide:no; mso-style-qformat:yes; mso-style-parent:""; margin:0in; margin-bottom:.0001pt; mso-pagination:widow-orphan; font-size:12.0pt; font-family:Calibri; mso-ascii-font-family:Calibri; mso-ascii-theme-font:minor-latin; mso-fareast-font-family:Calibri; mso-fareast-theme-font:minor-latin; mso-hansi-font-family:Calibri; mso-hansi-theme-font:minor-latin; mso-bidi-font-family:"Times New Roman"; mso-bidi-theme-font:minor-bidi;} .MsoChpDefault {mso-style-type:export-only; mso-default-props:yes; font-family:Calibri; mso-ascii-font-family:Calibri; mso-ascii-theme-font:minor-latin; mso-fareast-font-family:Calibri; mso-fareast-theme-font:minor-latin; mso-hansi-font-family:Calibri; mso-hansi-theme-font:minor-latin; mso-bidi-font-family:"Times New Roman"; mso-bidi-theme-font:minor-bidi;} @page WordSection1 {size:8.5in 11.0in; margin:1.0in 1.0in 1.0in 1.0in; mso-header-margin:.5in; mso-footer-margin:.5in; mso-paper-source:0;} div.WordSection1 {page:WordSection1;} --> </style> [FONT=&]They say the third time is the charm. This is the second time I have rebedded portlights. The first was ok, this time was good, but not great. So hopefully next time I will get it right. [/FONT]

[FONT=&]The first time on the E27 I tried to rebed the tempered glass in the frame using the "standard" rubber frame gasket. However, the glass was much thicker than standard and after two tries of purchasing gasket that did not fit, I ended up bedding it in place with Dow 795 and used butyl tape for the frame to cabintop. This has been waterproof for 5+ years but it was a messy job.

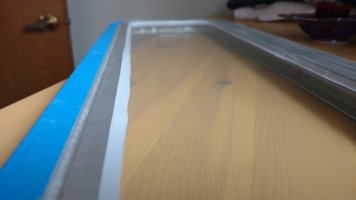

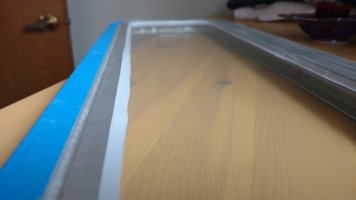

I just completed the first half of this job again, the sealing of the glass to the frame. I considered purchasing the gasket kit from CatalinaDirect, but with the frames suffering some corrosion and pitting, I figured it would be best to go the Dow 795 sealant route again. I spent many hours masking the frame and the glass, cleaned the channel and glass with Interlux 202, then acetone, then alcohol, used some leftover bits of gasket to center the glass in the frame, and made reference marks on the tape to center the glass piece all the way around. Then gooped up the channel with 795 and put the glass in, and smoothed it out. The first three I spent a ton of time smoothing it out with my finger and wiping up 795 from everywhere. This yielded a reasonably smooth and good seam, but with significant waviness. Definitely amateurish on close inspection. Finally on the last portlight I had an epiphany. Tools to smooth caulk are inexpensive, readily available, and there happened to be one sitting in my tool chest! Duh! The 45 angled portion was just right, and the results were utterly professional. Too bad the first three had already cured. Next time.

Lessons learned:

1. Use the old rubber gasket (cut down significantly) as spacers to center the glass in the aluminum channel.

2. Screw one half of each aluminum connector to the bottom of the channel before installing sealant.

3. Masking is unnecessary. Dow 795 cleans up easily with Kirkland brand Baby Wipes from Costco, or acetone or mineral spirits (I consider Baby Wipes to be an indispensable part of most boat projects).

4. Use the $3 dollar flexible caulk spreader (the 45 degree angle part) to smooth the caulk. This is the difference between good and great. [/FONT]

<style> <!-- /* Font Definitions */ @font-face {font-family:"Cambria Math"; panose-1:2 4 5 3 5 4 6 3 2 4; mso-font-charset:1; mso-generic-font-family:roman; mso-font-format

[FONT=&]The first time on the E27 I tried to rebed the tempered glass in the frame using the "standard" rubber frame gasket. However, the glass was much thicker than standard and after two tries of purchasing gasket that did not fit, I ended up bedding it in place with Dow 795 and used butyl tape for the frame to cabintop. This has been waterproof for 5+ years but it was a messy job.

I just completed the first half of this job again, the sealing of the glass to the frame. I considered purchasing the gasket kit from CatalinaDirect, but with the frames suffering some corrosion and pitting, I figured it would be best to go the Dow 795 sealant route again. I spent many hours masking the frame and the glass, cleaned the channel and glass with Interlux 202, then acetone, then alcohol, used some leftover bits of gasket to center the glass in the frame, and made reference marks on the tape to center the glass piece all the way around. Then gooped up the channel with 795 and put the glass in, and smoothed it out. The first three I spent a ton of time smoothing it out with my finger and wiping up 795 from everywhere. This yielded a reasonably smooth and good seam, but with significant waviness. Definitely amateurish on close inspection. Finally on the last portlight I had an epiphany. Tools to smooth caulk are inexpensive, readily available, and there happened to be one sitting in my tool chest! Duh! The 45 angled portion was just right, and the results were utterly professional. Too bad the first three had already cured. Next time.

Lessons learned:

1. Use the old rubber gasket (cut down significantly) as spacers to center the glass in the aluminum channel.

2. Screw one half of each aluminum connector to the bottom of the channel before installing sealant.

3. Masking is unnecessary. Dow 795 cleans up easily with Kirkland brand Baby Wipes from Costco, or acetone or mineral spirits (I consider Baby Wipes to be an indispensable part of most boat projects).

4. Use the $3 dollar flexible caulk spreader (the 45 degree angle part) to smooth the caulk. This is the difference between good and great. [/FONT]

Last edited:

port light removal

Adam,

Last year I removed 4 port lights and learned a lesson or two just like you are.

2 ports I used putty knives and sharp objects to cut the putty away from the frame.

Then one day an old hand walked by handed me a pry bar and a scrap of wood and said, "just put that pry bar in thra and she'll pop right out"

Holy Crap, I spent weekends cutting two port lights and 15 minutes on the last two.

Try it, it might work.

MJS

Adam,

Last year I removed 4 port lights and learned a lesson or two just like you are.

2 ports I used putty knives and sharp objects to cut the putty away from the frame.

Then one day an old hand walked by handed me a pry bar and a scrap of wood and said, "just put that pry bar in thra and she'll pop right out"

Holy Crap, I spent weekends cutting two port lights and 15 minutes on the last two.

Try it, it might work.

MJS

Portlights

I would be very interested in seeing your notes. I have a 1977, 27 and need to replace the port lights. I am considering surface mount on the exterior.

Any pics and guidance is much apprenticed.

Thanks

Bink

anselmrichards@hotmail.com

I would be very interested in seeing your notes. I have a 1977, 27 and need to replace the port lights. I am considering surface mount on the exterior.

Any pics and guidance is much apprenticed.

Thanks

Bink

anselmrichards@hotmail.com

Reply - Bink

Bink,

As a newbie to sailboat maintenance, I did what a lot of others have done. I removed the frame screws and saw a lot of white stuff.

I tried many ways to remove it but it is tough stuff. I ended up using a number of sharp instruments and a lot of hours and magic words.

Then one day an old yard hand walked by and offered a hand. He took a small crowbar, a thin piece of shim and wedged it into a small space between the exterior frame.

With gentle prodding, he got that sucker out in about 7 minutes with out bending the frame. The trick was to get it started enough to get leverage and then work your way around.

I took out the last frame myself in about 15 minutes with only minor frame bends that I later smoothed out.

When I put the frames back in I used butyl tape. the minor imperfections in the frame were negated because the butyl filled them in.

That's my story and experience

Bink,

As a newbie to sailboat maintenance, I did what a lot of others have done. I removed the frame screws and saw a lot of white stuff.

I tried many ways to remove it but it is tough stuff. I ended up using a number of sharp instruments and a lot of hours and magic words.

Then one day an old yard hand walked by and offered a hand. He took a small crowbar, a thin piece of shim and wedged it into a small space between the exterior frame.

With gentle prodding, he got that sucker out in about 7 minutes with out bending the frame. The trick was to get it started enough to get leverage and then work your way around.

I took out the last frame myself in about 15 minutes with only minor frame bends that I later smoothed out.

When I put the frames back in I used butyl tape. the minor imperfections in the frame were negated because the butyl filled them in.

That's my story and experience

frick

Sustaining Member

Replacing port lights with solid plastic

I had a friend who replaced his c &c ports with smoked laxan... Looked very nice. He routed out the edges so it would drop in...

When I took the ports out of my E29 I noticed that to do the same thing as my friend, I would have to finish the all inside edges of every port. That much bigger job that rebedding the Ports.

Rick

I had a friend who replaced his c &c ports with smoked laxan... Looked very nice. He routed out the edges so it would drop in...

When I took the ports out of my E29 I noticed that to do the same thing as my friend, I would have to finish the all inside edges of every port. That much bigger job that rebedding the Ports.

Rick

Ian S

Member III

DO NOT USE BUTYL TAPE!! Butyl remains pliable throughout it's life. it will continue to ooze out a gummy, terrible black mess. It is not the right product.

There is a reason porlights are NEVER bedded with butyl from the MFG. You have two choices, maybe three

Here is my preference in order. After having installed many many port lights. fyi 4200 has a more adhesive quality which is really unnecessary. You do not need to mask of the area either, that's even messier BC the tape will not be strong enough to tear the excess material cleanly. Allow the excess cure and scrape with an acrylic / plastic scraper. If there is any residue left a gentle wipe with some Denatured alcohol, or acetone will suffice. do not get either of these chemicals on your new lenses, as they will attack acrylic. reapply some wax to the gel coat when complete. Also of great importance. the ports once bedded should NOT be fully tightened down. bed them, set 2-5 days and then give them their final tightening. This is the #1 reason newly bedded equipment leaks. were are trying to from a gasket here. this will leave enough material behind to remain pliable, and flexible enough to compensate for normal flexing of the boat w/o breaking the seal.

#1 Dow 795

#2 Boat life caulk (Polysulfide)

#3 4200 (Polysulfide)

Best of Luck! Capt. Ian

There is a reason porlights are NEVER bedded with butyl from the MFG. You have two choices, maybe three

Here is my preference in order. After having installed many many port lights. fyi 4200 has a more adhesive quality which is really unnecessary. You do not need to mask of the area either, that's even messier BC the tape will not be strong enough to tear the excess material cleanly. Allow the excess cure and scrape with an acrylic / plastic scraper. If there is any residue left a gentle wipe with some Denatured alcohol, or acetone will suffice. do not get either of these chemicals on your new lenses, as they will attack acrylic. reapply some wax to the gel coat when complete. Also of great importance. the ports once bedded should NOT be fully tightened down. bed them, set 2-5 days and then give them their final tightening. This is the #1 reason newly bedded equipment leaks. were are trying to from a gasket here. this will leave enough material behind to remain pliable, and flexible enough to compensate for normal flexing of the boat w/o breaking the seal.

#1 Dow 795

#2 Boat life caulk (Polysulfide)

#3 4200 (Polysulfide)

Best of Luck! Capt. Ian

Last edited:

DO NOT USE BUTYL TAPE!!

... snip ...

do not get either of these chemicals on your new lenses, as they will attack acrylic.

... snip ...

#1 Dow 795

#2 Boat life caulk (Polysulfide)

#3 4200 (Polysulfide)

Best of Luck! Capt. Ian

3M 4200 is a polyurethane (not polysulfide) and may attack some plastics, as the instructions state. Test first to see if it softens or crazes a plastic lens. I have used Sikaflex products when bedding acrylic into aluminum.

Edited to include incompatibility with acrylic

Last edited:

Re-bedding plastics

I used black BoatLife (brand) Life Seal (product) to bed our four new Lexan external fixed ports in 1995. No problem or degradation of the plastics at all. It was not supposed to harm the plastic, and it has not. I recommend the product.

I have been using their clear version for many years for routine hardware bedding, also.

Of course this is one more example of there being several correct answers to a question!

I used black BoatLife (brand) Life Seal (product) to bed our four new Lexan external fixed ports in 1995. No problem or degradation of the plastics at all. It was not supposed to harm the plastic, and it has not. I recommend the product.

I have been using their clear version for many years for routine hardware bedding, also.

Of course this is one more example of there being several correct answers to a question!