I still like teak.

He said quietly.

These beautiful Starboard projects will provide another perspective

. Actually, I like teak too. More on that at the end.

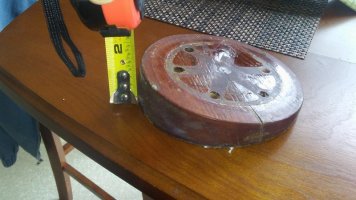

My first Starboard project was a 3 inch pedestal lift to accommodate a larger steering wheel. It's made from two 1.5 inch thick pieces.

Next came two mast cam bases to fit the contour of the mast in 1/2 inch black starboard. These could have been 1/4 inch thick and still absorbed the small amount of curve.

Third, a 1/2 inch thick base for my starboard cabin top winch to fit the slight side to side curve of the cabin top. This could have been 1/4 inch thick also as no lift was required.

Next was a 1.5 inch lift of my spin pole deck chock to get the center of the pole off the deck.

Last was a plug shaped from 1.5 inch thick Starboard to fill a toe rail scupper which drains directly over my fuel tank vent.

I think the scupper plug has to be Starboard to blend in and resist moisture. The black mast cam base blends in better in black on my mast. The winch base is so thin (and could be thinner) that there would be very little teak exposed to show off and I would worry about it cracking along the grain- a problem with teak.

I think you could make a case that the spin pole chock lift and the wheel lift pieces would look good (better?) in teak. I think I prefer these in white and blending in and certainly like the lack of maintenance. It's worth putting some thought and effort into the shape of these pieces to keep them from looking too industrial.

I have about six other teak lifting and angle blocks plus the hand rails which do add a nice look and I wouldn't change them to Starboard just to avoid maintenance,

Mark