Tooluser

Flǎneur

"There is no desire so universal as the desire to edit someone else's copy, sail trim, or electrical system."

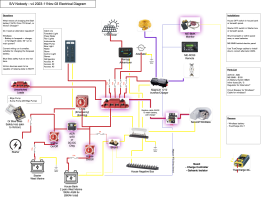

My new E381's electrical system is serviceable, and somewhat upgraded, but a bit heterogenous.

For example, it still has a bow battery for the windlass, but no real charging plan for it. Many cables are undersized, and charging sources are connected to only one battery or another, yielding anxiety for longer cruises. I've designed a new layout and I'd love critique and commentary. It's already begun on my blog post (thanks @Nick J !) so I wanted to move it here before it grew too much over on the blogs! I'd love to hear what you've done with your 40-year-old electrical system and what you wish you had.

Design Goals:

- Any charge source will charge all batteries

- Reasonable State-of-Charge readout available for house bank

- Emergency backup ability, but otherwise automated

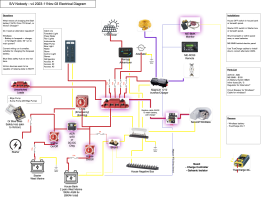

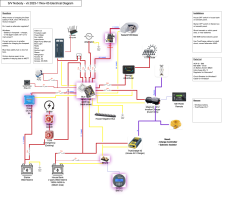

The original design:

You can see the multiple chargers, ability of the alternator to charge only the start battery (which doesn't seem much usage, since it only starts a small diesel, thus wasting the existence of the alternator and flat PNW days), and the dizzying multiple-1/2/B switches I still don't understand.

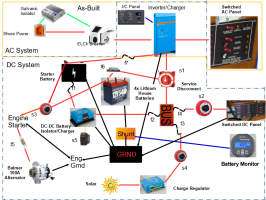

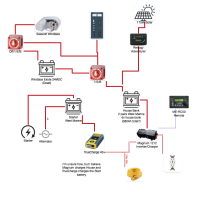

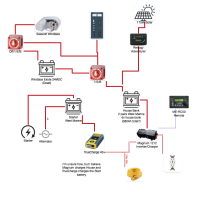

Below I've removed the windlass battery and replaced it with two large 2AWG cables to the forepeak. The starter battery now charges from the house bank via a DC-DC charger - here it shows as an ACR, but I'll actually use a Victron Orion, I think. I've added a battery monitor and missing switches.

My open questions I'd love your thoughts on:

- Is anyone going to talk me into keeping the bow battery for the windlass?

- I could get Magnum's battery monitor, which integrates with their remote, or add a Victron. Victron would be another 'box', but they have a reputation for being much more open-source and flexible. (And a hassle to get support from. . . . any Victron owners?)

My new E381's electrical system is serviceable, and somewhat upgraded, but a bit heterogenous.

For example, it still has a bow battery for the windlass, but no real charging plan for it. Many cables are undersized, and charging sources are connected to only one battery or another, yielding anxiety for longer cruises. I've designed a new layout and I'd love critique and commentary. It's already begun on my blog post (thanks @Nick J !) so I wanted to move it here before it grew too much over on the blogs! I'd love to hear what you've done with your 40-year-old electrical system and what you wish you had.

Design Goals:

- Any charge source will charge all batteries

- Reasonable State-of-Charge readout available for house bank

- Emergency backup ability, but otherwise automated

The original design:

You can see the multiple chargers, ability of the alternator to charge only the start battery (which doesn't seem much usage, since it only starts a small diesel, thus wasting the existence of the alternator and flat PNW days), and the dizzying multiple-1/2/B switches I still don't understand.

Below I've removed the windlass battery and replaced it with two large 2AWG cables to the forepeak. The starter battery now charges from the house bank via a DC-DC charger - here it shows as an ACR, but I'll actually use a Victron Orion, I think. I've added a battery monitor and missing switches.

My open questions I'd love your thoughts on:

- Is anyone going to talk me into keeping the bow battery for the windlass?

- I could get Magnum's battery monitor, which integrates with their remote, or add a Victron. Victron would be another 'box', but they have a reputation for being much more open-source and flexible. (And a hassle to get support from. . . . any Victron owners?)