I think the original design was a (brilliant) aesthetic that allowed the tops and bottoms of the portlights to perfectly parallel the horizontal line molded into the top of the cabin sides and the line of the deck sheer.

Unfortunately it's hell for us replacing things. Very recently (weeks ago?) I wrapped up replacing all of my E-29 portlights with opening lewmar size 1, 4R, and 4L's.

The forward long port lights required only a little trimming to fit, the after port lights required filling and trimming. I didn't take any pictures while I was working on it unfortunately, but -- The method I used to do this was as follows:

(On my boat, the outer cabintop is about 3/16" to 1/4" thick, the inner ranged from 1/8th" to 3/16". The screws that come with the lewmar lights are too long for any of the lights on my E29.. I had to order shorter screws from lewmar, which took 4 months to arrive.. You'll want to make sure you have all the right bits before you start this project)

1) Make template of window cutout in 1/4" plywood from both dimensions in literature and measuring actual 4L/4R portlight (literature doesn't have all the required data but has useful information like radius of corners). Use same template for both sizes.

2) Take template, base it against the forward edge and bottom edge of existing cutout

3) Trace around template onto gelcoat with pencil where possible. There was a long gap between the template and the top of the cutout from the upper forward corner down to the upper side of the aft-most corner; the maximum width of this gap was about 3 cm -- 1 & 1/4" at the top of the taper on mine.

4) Cut out an appropriately long, ~6-7cm wide piece of 1/8th" G10 fiberglass, cram it in between the inner liner and outer hull such that it fills the gap you infer from your pencil marks and then some. It's important to have some overlap for the next step. After you've verified with your template you've got it right, make some more alignment marks on the G10, pull it out, prep all the edges and fill gap with thickened epoxy and glue the g10 into place.

5) Come back draw the top of your template over the G10. (reprep edges if necessary and) Slop some epoxy fairing compound (that will remain a

little flexible after cure, I used total boat total fair) onto both the inside and outside to make it proud of the gelcoat. Took me a couple rounds to get it done, retracing the template each time to make sure you've covered the important area. Finally, sand it all flush with the gelcoat, I used my 6" RO sander on the outside and a 3" festool rotex 90 on the inside, with 80 grit to accomplish this..

6) Re-trace your template again over the new filler, come back in with the jigsaw, and go to town. Be wary of the blade overheating...

At this point, I painted the new work outside and the inside cabin liner all around. after the paint cured for 4 or 5 days, I installed the portlights with Maine Sail's butyl tape

After it's all said and done, you can't tell that it was originally a different size hole. The fairing compound might crack (I kept my cutout to test for flexibility now and then..) though to be honest, 1/8th" G10 seems more rigid than 1/4" 1971 Ericson layup, so maybe not. If it cracks, whatever, I'll fix it then.

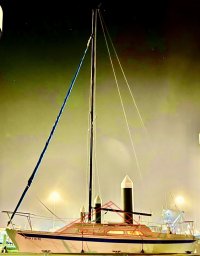

Back to Bruce King's aesthetic though -- the top of the portlight no longer parallels the line molded into the cabintop.

View attachment 41598

It's definitely not as pretty, but in my case I had no choice (Old lights were leaking and sealed in with gobs of some compound that destroyed the frames on removal.) To Loren's point there is a slight curve in the cabinside, but the lights went in, open and close without much trouble. Having them open is pretty heavenly, as well.