I replaced an old 1990s(?) vintage Xintex S-2 propane system with the latest (2019) Xintex FIREBOY SYSTEMS P-1BS-R Propane Detector w/Sensor & Valve (single sensor) system. The reason for working on the system was that the propane solenoid valve located at the tank in the cockpit locker had failed open, which is not safe. I think it probably corroded over the years and then would not close one day on a 2019 cruise. I decided to replace the old system completely but not due to any particular performance reason. It just felt like it was time to refresh the system.

Performance comparison and comments on propane sensor life. The propane sensor on the old S-2 system seems to work fine, at least as compared to the brand new one. I could not do a true quantitative evaluation, but it detected butane and propane just as quickly as the new sensor during my tests. The sensors are powered, active components, so perhaps the possibility of failure of the electronics in the sensor is one reason the manufacturer suggests periodic sensor replacement. The single sensor is located underneath the stove in the galley. The old system had a dual sensor capacity but was wired to function with only one sensor.

System operation. The two systems and controls were essentially the same in operation. At power on a sensor test was run before the valve could be operated. After a few seconds the old system sounded the audible alarm and lit the red warning lights that had to be canceled (muted) manually. The new system ran through the self-test much faster and then lit the green OK light at the top with no audible beep. Both have a Test switch for the sensors and a mute for the alarm. The Test and Mute button are the same on the new smaller control panel. Both have the valve on-off button and valve On or open is indicated with a green light on the panel.

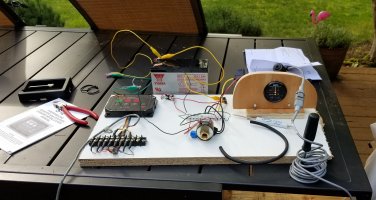

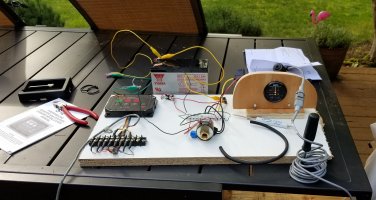

Propane detection and valve operation. I tested and compared the two systems before committing to the new system. The old system and new system were mounted on a board to make it easy to carry them around and to switch between systems while testing. Initial tests were done with a butane lighter and both systems performed the same as far as detection of gas. I did an outdoor test with my gas grill as a source of the propane leak. Again, good performance in detection of the propane for each system and prompt automatic closure of the valve. The warning lights on both stayed on while propane was being sensed and went out when the propane cleared.

The difference in operation came while waiting for the propane to dissipate. The old S-2 system WOULD NOT allow the valve to be opened while the warning light was on. The new system WOULD allow the valve to be opened again after Muting the audible alarm, and while the Danger light was still lit. This is not an improvement over the old system, in my opinion. I wrote the company to confirm that this is the intended operation of the new system. Further testing of the new system showed, however, that the propane valve would again close automatically after approximately 20 seconds if propane was still being sensed. After discovering this I decided to go ahead the new system installation. Of course, everyone will know not to turn on the propane with a Danger light on, right?

Installation notes. My E-38 has the aft right galley and aft left quarter berth/nav station. I installed the new round panel in the same spot as the old, under the companionway steps next to the sink. The hole for the wires was only one inch in diameter and had to be enlarged to a bit over 2 inches to fit the barrel of the new panel. I made a plastic sheet to cover the screw holes from the old panel. The new propane sensor wire had ¾” wide connectors on each end and the manual strongly warned against cutting the wire. Therefore, I had to change the routing of the sensor wire and not use the PVC conduits. This was good because the old one was routed under the sink, among the bilge pump, water tank control valves, and thru-hulls. The excess wire was bundled up with the extra fridge wiring and was a mess. The new routing went behind the fridge, under the counter, and out to the lazarette behind the wine rack. Plenty of wire available for that. The new sensor was mounted in the same location. The round hole was enlarged slightly, and the sensor was mounted lower, using spacers, to account for the sensor opening differences. I re-used the bent aluminum mounting platform from the old sensor, so I didn’t deform the plastic case of the new sensor.