Retired from newspapers and television, currently sailing Thelonious II, a 1984 Ericson 381.

The Eastport pram is 7 feet 9 inches long, weighs only about 65 pounds, and fits nicely on the foredeck.

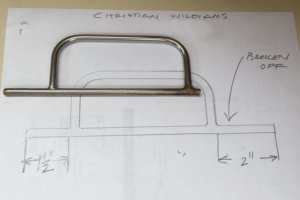

I reshaped the transom to conform to the camber, and padded it at the two contact points. The Taylor bumper rail makes a permanent soft landing for the bow. Two stern lines tie pretty well to the dorade guard before the mast, but that is where tying pretty well ends...

You do not have permission to view the full content of this entry.

Log in or register now.