Interestingly, I just changed out my packing two days ago....

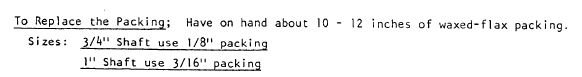

Anyway, when it comes to things like this, assume nothing. Don't waste you time reading the owner's manual. I will say that 1/8" sounds improbably small if you have 1" shaft, but that depends on the particular stuffing box in question. I use 1/8" packing but the shaft on my boat is 3/4". It's a baby engine with a baby stuffing box.

The best thing to do, until you determine for certain the packing size, is to purchase a couple of different sizes to see how they fit.

So how should the packing fit? It should not be floppy loose but you should not have to beat it in, either. It should fit snugly but not be crazy tight. I know that's a bit subjective, though I'm not sure of a better way to describe it. Realize that your old packing may be swollen and deformed, so measuring it could be misleading.

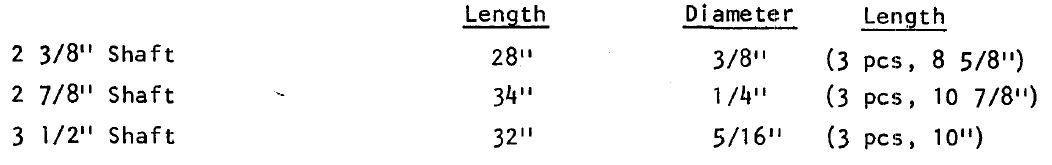

You've already gotten the old packing out, and that is in many ways the worst part of the job. What I find works best is a small diameter straight awl. I come in at an angle to the shaft, which is necessary because if you come in above and parallel to the shaft, the stuffing box hose is going to get in the way of the handle on the awl. So, coming in from the side, I press in the awl until it penetrates the packing and then push the awl to the side so that the end of the packing comes out of the nut. Then I hold that end and rotate the packing nut so that the packing unwinds and comes easily out of the nut. I hope this makes sense.

To replace with new: I add one ring at a time, screwing down the nut to press the ring to the front of the nut. Then I unscrew it and add the next ring, and then the next for a total of three. I stagger the cuts as best I can, though it's anyone's guess as to where the cuts really wind up after pressing them in as I've just described.

I'm using the GoreTex "virtually dripless" packing. The ideal adjustment, if you can get it, is for it to weep slightly when the shaft is rotating and to not drip when the engine is off. That's ideal, but if it drips occasionally even when the engine is off that's no big deal. Don't make it overly tight, though, as it might run too hot.

I've had some times where getting out the old packing was a bear, but when I did it on Monday the job went very smoothly for some reason. Maybe that means the next boat job is going to go horribly awry, so as to bring the universe back into equilibrium.

It took me about 45 minutes to cut the rings, remove the old packing, and then insert the new ones. Then I ran the engine for a bit to play with the adjustment.

By the way: On my boat, at least, there was no issue whatever with doing this in the water. I have a tiny automatic bilge pump but it easily kept up with the flow.