Hello everybody, I am looking at taking on an Ericson 34-2 as a project. Overall the boat is in good condition and was well cared for by the previous owner. They owned the boat for about 20 years and cruised the coast of Maine every year with minimal issues. A few years ago they decided to sell the boat. When a prospective buyer came aboard he found that there was some major structural damage. The TAFG was cracked in one of the large transverse stringers in front of the engine. The sale fell through and the owners hired someone to pull the cabin sole up to figure out the extent of the damage. When the whole grid was exposed they found that the tabbing in the sections of the grid between the gally sink and nav station and a few feet forward of that had completely separated from the hull by about an inch. At that point the owners discovered their insurance would not cover the repairs so everything was stopped and the boat has been sitting for a few years.

From what I can figure out nobody knows exactly what caused the damage. The owners claim they never had a hard grounding while they owned the boat. A survey done after repairs were started did find evidence of a grounding in the bottom front of the keel but it is vey old and covered in several layers of bottom paint. The insurance company concluded that the damage existed from before the current owners bought the boat, hence why they would not cover the repairs. Another theory is that water got inside the boat at some point and froze, causing the cracking of the stringer and the separation of the TAFG from the hull. It is also interesting that I can not find any evidence of bulkheads or furniture shifting and getting pushed around, although the stringer has a clear hump in it. There is a slight separation of the head wall and the shower floor but that’s it.

If it was just the cracked stringer I would think the repair would be relatively straight forward to grind it out and re glass it. If the tabbing had simply delaminated from the hull I would grind everything down and re glass it. It’s the separation between the grid and the hull that’s the interesting part. There is no obvious deformity on the hull when I look at it from the outside and it is not clear that the cracked stringer is the complete cause of the separation either.

I am curious if you guys have any ideas of what could have caused this and weather you think a repair is possible/worth it. I know other brands of boats with structural grids have had issues with separation and cracking but I have never heard of it happening to an Ericson.

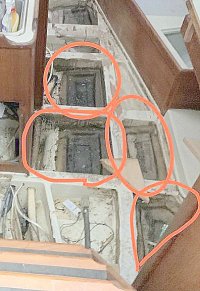

I have attached some photos that best show the damage. The red circles show where there is separation.

Thanks for your thoughts!

From what I can figure out nobody knows exactly what caused the damage. The owners claim they never had a hard grounding while they owned the boat. A survey done after repairs were started did find evidence of a grounding in the bottom front of the keel but it is vey old and covered in several layers of bottom paint. The insurance company concluded that the damage existed from before the current owners bought the boat, hence why they would not cover the repairs. Another theory is that water got inside the boat at some point and froze, causing the cracking of the stringer and the separation of the TAFG from the hull. It is also interesting that I can not find any evidence of bulkheads or furniture shifting and getting pushed around, although the stringer has a clear hump in it. There is a slight separation of the head wall and the shower floor but that’s it.

If it was just the cracked stringer I would think the repair would be relatively straight forward to grind it out and re glass it. If the tabbing had simply delaminated from the hull I would grind everything down and re glass it. It’s the separation between the grid and the hull that’s the interesting part. There is no obvious deformity on the hull when I look at it from the outside and it is not clear that the cracked stringer is the complete cause of the separation either.

I am curious if you guys have any ideas of what could have caused this and weather you think a repair is possible/worth it. I know other brands of boats with structural grids have had issues with separation and cracking but I have never heard of it happening to an Ericson.

I have attached some photos that best show the damage. The red circles show where there is separation.

Thanks for your thoughts!

Attachments

-

IMG_4228.jpeg114.9 KB · Views: 127

IMG_4228.jpeg114.9 KB · Views: 127 -

IMG_4215.jpeg122 KB · Views: 121

IMG_4215.jpeg122 KB · Views: 121 -

IMG_4214.jpeg261.5 KB · Views: 113

IMG_4214.jpeg261.5 KB · Views: 113 -

IMG_4218.jpeg241.7 KB · Views: 113

IMG_4218.jpeg241.7 KB · Views: 113 -

IMG_4239.jpeg159 KB · Views: 117

IMG_4239.jpeg159 KB · Views: 117 -

IMG_4238.jpeg148.6 KB · Views: 116

IMG_4238.jpeg148.6 KB · Views: 116 -

IMG_4242.jpeg106.9 KB · Views: 116

IMG_4242.jpeg106.9 KB · Views: 116 -

IMG_4241.jpeg164.7 KB · Views: 120

IMG_4241.jpeg164.7 KB · Views: 120 -

IMG_4220.jpeg305.2 KB · Views: 126

IMG_4220.jpeg305.2 KB · Views: 126