Frank Langer

1984 Ericson 30+, Nanaimo, BC

I had a great sail underway yesterday in 16 knot winds, boat going 6.8 knots, heeled about 20 degrees. All of a sudden the mainsail began to drop, and I noticed the professionally done splice attaching the halyard to shackle to head of the sail had let go, halyard broken. I was able to get the sail flaked and got back to dock safely with headsail.

Today I went up the mast tower at our yacht club to see if I could spot a loose end of halyard but the openings at the mast head are tiny, no halyard visible.

I threaded a 50' electric fishtape through an opening for another halyard to the mast to (not easy, lots of twisting, push/pull) and was able to thread a 3/16" messenger line up the mast, around the sheave for the mainsail, and back to deck level, to allow me to install a new halyard.

I then pulled on the old broken halyard, expecting it to come freely down the mast and out the exit fitting. Unfortunately most of it came ok but the last bit, not sure how much, got stuck and won't move. I tried with the fishtape to move the old halyard up the mast to free it, but that didn't work.

So my problem is an end of the old halyard stuck part way up the mast, with no way to see what is causing that. The mast is deck stepped (1984 E30+).

If anyone has any ideas on how to get the old halyard unstuck and out, I'd really appreciate it!!

Boating should be fun, but these episodes are not.

Frank

Today I went up the mast tower at our yacht club to see if I could spot a loose end of halyard but the openings at the mast head are tiny, no halyard visible.

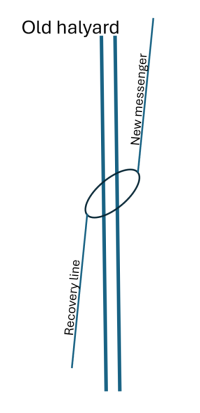

I threaded a 50' electric fishtape through an opening for another halyard to the mast to (not easy, lots of twisting, push/pull) and was able to thread a 3/16" messenger line up the mast, around the sheave for the mainsail, and back to deck level, to allow me to install a new halyard.

I then pulled on the old broken halyard, expecting it to come freely down the mast and out the exit fitting. Unfortunately most of it came ok but the last bit, not sure how much, got stuck and won't move. I tried with the fishtape to move the old halyard up the mast to free it, but that didn't work.

So my problem is an end of the old halyard stuck part way up the mast, with no way to see what is causing that. The mast is deck stepped (1984 E30+).

If anyone has any ideas on how to get the old halyard unstuck and out, I'd really appreciate it!!

Boating should be fun, but these episodes are not.

Frank

Last edited: