Phr3d

Member III

Good morning all,

While sailing last time in the bay at San Diego (There was a noticeable need to trim differently between puffs), I was amazed at how difficult it was to get the mainsheet trimmed. I would have preferred it was on the outside starboard winch (Lewmar 16) rather than the one further forward (Lewmar 30) for grinding. It is thick, soft, stretchy line.

I've been looking for solutions. So far, I've identified the following:

-Stop procrastinating and push/pull some heavy weights

-Getting more "slippery" line (what kind is that?)

-Changing the fiddle block (the smaller block is aggravating friction?)

-Increasing purchase with new blocks (6:1, 8:1?)

-Some combination of the above

I did a search but did not find any low hanging fruit. I'm interested on how others have improved this situation...

Vang

It is installed with the cleat at the mast base. Is it this way because it was reaved through a block at the mast base to the cockpit? Or just to get the line "out of the way" of the companionway? The cleat does block the hatch from opening...

I'm going to try to turn it around so the line can be cleated/uncleated from cockpit.

Outhaul

It is ran through a clutch on the port side. The car was stuck and block frozen. I got it moving some...

Reefing Lines

They are through the boom and not touching the sail. The main is difficult (slides stick) to raise/lower at about 3/4 height. I'm going to go up there and inspect/clean it first chance. I wonder if the reefing lines were removed to lower resistance?

Topping Lift

I started wondering if there was a line for that?

Cunningham

I didn't see one, but I think I might need one...

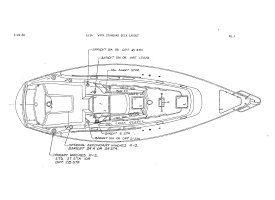

Winches

What winch do you use for which lines?

Telltales

They are missing on the main. Is this an expensive thing to have repaired?

Miscellaneous Updates

Bottom paint complete!

Name change in process

I found the emergency tiller (still in bubble wrap)

Signaling kit included some 2003 vintage flares

While sailing last time in the bay at San Diego (There was a noticeable need to trim differently between puffs), I was amazed at how difficult it was to get the mainsheet trimmed. I would have preferred it was on the outside starboard winch (Lewmar 16) rather than the one further forward (Lewmar 30) for grinding. It is thick, soft, stretchy line.

I've been looking for solutions. So far, I've identified the following:

-Stop procrastinating and push/pull some heavy weights

-Getting more "slippery" line (what kind is that?)

-Changing the fiddle block (the smaller block is aggravating friction?)

-Increasing purchase with new blocks (6:1, 8:1?)

-Some combination of the above

I did a search but did not find any low hanging fruit. I'm interested on how others have improved this situation...

Vang

It is installed with the cleat at the mast base. Is it this way because it was reaved through a block at the mast base to the cockpit? Or just to get the line "out of the way" of the companionway? The cleat does block the hatch from opening...

I'm going to try to turn it around so the line can be cleated/uncleated from cockpit.

Outhaul

It is ran through a clutch on the port side. The car was stuck and block frozen. I got it moving some...

Reefing Lines

They are through the boom and not touching the sail. The main is difficult (slides stick) to raise/lower at about 3/4 height. I'm going to go up there and inspect/clean it first chance. I wonder if the reefing lines were removed to lower resistance?

Topping Lift

I started wondering if there was a line for that?

Cunningham

I didn't see one, but I think I might need one...

Winches

What winch do you use for which lines?

Telltales

They are missing on the main. Is this an expensive thing to have repaired?

Miscellaneous Updates

Bottom paint complete!

Name change in process

I found the emergency tiller (still in bubble wrap)

Signaling kit included some 2003 vintage flares