You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Any Experience with Raymarine EV-200 Autopilot in an E35-2?

Teranodon

Member III

I have no experience with the ev-200, but the price difference with the ev-100 is staggering. Also, the way it moves the rudder scares me. Without the mechanical advantage of the steering wheel, the motor torque must be enormous. I would worry about longevity. Still, given the known flaws of the ev-100, it might be a wise choice...

Known flaws?

Wasn't there someone posting here fairly recently about acquiring a wheel pilot from http://www.cptautopilot.com

??

Given it's reputation for reliability, it might be an alternative to the more common Raymarine (former Autohelm) drive motor device.

Maybe.

??

Given it's reputation for reliability, it might be an alternative to the more common Raymarine (former Autohelm) drive motor device.

Maybe.

David Grimm

E38-200

You can check out my EV-200 Linear Drive AP in operation here.

Check out my other not so professional videos that go over installation.

Dave

Check out my other not so professional videos that go over installation.

Dave

WindHorse

Member I

Nice setup, David. The checked out your installation pics. Lots of work! My 35-2 is a bit different. The rudder shaft is longer and also angled forward and I am auxiliary tiller mount in the cockpit, so there is lots of real estate to connect to. The engineering will be a bit tricky, however, as I would need to manufacture some sort of bridge/plate between the existing steering pulley mounts on which to mount the actuator at an angle perpendicular to the shaft... Would LOVE to see how any other 35-2s have done this before reinventing it!

Attachments

WindHorse

Member I

I should add that mounting from the forward transom would be difficult if not impossible, as it’s virtually inaccessible...Nice setup, David. The checked out your installation pics. Lots of work! My 35-2 is a bit different. The rudder shaft is longer and also angled forward and I am auxiliary tiller mount in the cockpit, so there is lots of real estate to connect to. The engineering will be a bit tricky, however, as I would need to manufacture some sort of bridge/plate between the existing steering pulley mounts on which to mount the actuator at an angle perpendicular to the shaft... Would LOVE to see how any other 35-2s have done this before reinventing it!

David Grimm

E38-200

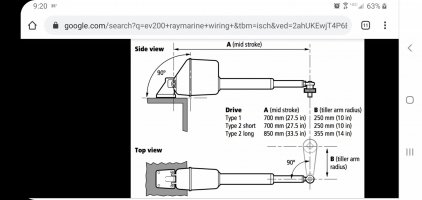

Shawn, The target is to align the drive unit 90 degrees and 10 inches out from the center of the rudder post for full range non binding motion of the rudder. I had no idea any of this would be possible on my vessel prior to purchasing the AP. I made a temporary rudder arm out of a 2x6 and a temporary rudder spacer out of pvc pipe, that made it clear to me where the drive unit would have to live. The next challange was designing a structure to hold it all in place.

Attachments

Great planning process; building a mockup is how I have approached several "tight fit" projects. Interesting that your rudder post and stuffing box looks identical to ours. Same guys may have built it, perhaps.

38-200 Below Deck Linear Drive Installation Pics and Information (Autopilot)

Finished this project today. Thought I'd share this because I'm stoked and so other people may have better luck than i had when trying to find information before starting. Happy to answer any questions and to hear if anyone sees something that may cause problems down the line... Linear drive...

gadangit

Member III

I suspect your 1970 E35 is very similar to our 1972 E39.

I don't have any pictures that show how I did it, but here are a couple that show the result. The 39 also has a forward tilting quadrant, so getting the alignment to a constant angle changing hull required a decent mockup. I built up a fiberglass and plywood structure on the hull to mount the hydraulic ram. And bolted a hunk of G10 to the quadrant to attach both the arm and rudder angle measurer thing.

The G10 on the quadrant allowed a bit of flexibility to the final through bolt position and avoided the cost of that expensive tiller arm that you can buy.

I don't have any pictures that show how I did it, but here are a couple that show the result. The 39 also has a forward tilting quadrant, so getting the alignment to a constant angle changing hull required a decent mockup. I built up a fiberglass and plywood structure on the hull to mount the hydraulic ram. And bolted a hunk of G10 to the quadrant to attach both the arm and rudder angle measurer thing.

The G10 on the quadrant allowed a bit of flexibility to the final through bolt position and avoided the cost of that expensive tiller arm that you can buy.

Attachments

WindHorse

Member I

Innovative approach with the G10. I've read recommendations against messing with the quadrant, but it looks like you distributed the load over the whole things, so I can't imagine why that would be a problem--so long as the actuator is aligned perfectly on the same plane... Now you've got me thinking...I suspect your 1970 E35 is very similar to our 1972 E39.

I don't have any pictures that show how I did it, but here are a couple that show the result. The 39 also has a forward tilting quadrant, so getting the alignment to a constant angle changing hull required a decent mockup. I built up a fiberglass and plywood structure on the hull to mount the hydraulic ram. And bolted a hunk of G10 to the quadrant to attach both the arm and rudder angle measurer thing.

The G10 on the quadrant allowed a bit of flexibility to the final through bolt position and avoided the cost of that expensive tiller arm that you can buy.

gadangit

Member III

Getting the correct swing plane isn't that hard. I think I clamped a 1x4 to the quadrant and hot glued a bunch of pieces of slivers of wood to both edges of the 1x4 down to the hull. It looked like a crazy battle axe when I was done. The tips of the slivers perfectly transcribed the hull curve and the flat 1x4 gave me the swing plane of the quadrant. It was down to execution after that.

Of course, I was into it about 10 hours curled up under the lazarette just staring prior to that.

Chris

Of course, I was into it about 10 hours curled up under the lazarette just staring prior to that.

Chris

gadangit

Member III

Baslin

Member III

Loren,Wasn't there someone posting here fairly recently about acquiring a wheel pilot from http://www.cptautopilot.com

??

Given it's reputation for reliability, it might be an alternative to the more common Raymarine (former Autohelm) drive motor device.

Maybe.

We recently installed the CPT Wheel Pilot on our E38. We have had no issues with it so far. It has worked well on all points of sail

Here's a link:

CPT Wheel Pilot

For anyone considering a wheel pilot install, I highly recommend the CPT Wheel Pilot. It is a very robust (86 ft lbs thrust), stand alone system and the install is very easy. Took about an hour. Longest part was running the power cable through the pedestal. We took our E38 for a test sail...- Baslin

- Thread

- Aug 10, 2020

- Replies: 4

- Forum: Maintenance & Mechanical

WindHorse

Member I

FYI, for those following...I elected to go with the EV-100 wheel pilot, and I'm very satisfied. I still have to take the wheel in rough conditions or on a run in shifty/gusty wind, but I imagine that would be true in either case. I gather a below-deck linear drive might be slightly fast reacting in weather helm moments, etc...but the price was right and installation very manageable. For longer voyages, I will be looking for a wind vane...

I did the same. I debated on going with a linear drive EV-200, as I sail 75% of the time solo but ended up purchasing a new EV-100 early last year. Same here - it does not do well under gusty conditions but for the most part, it is adequate and does a good job tracking a course. Also less amp draw than a Ev-200.