skipper007

Member II

Did we cheat?

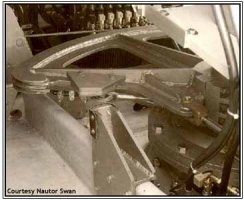

So MacGyver and I gave up on trying to get all of the rotten wood out. It actually appears as though there are two layers of glass holding 2 layers of wood spanning the distance between the forward and aft cockpit bathtubs (~20x24"). The boat yard said we'd pay more to have them replace the wood than we paid for the boat. The manager also said the strength was in the fiberglass not the wood - don't worry about leaving the rotten wood. We followed their suggestion.

What we did is remove all of the rotten wood we could get to. We were left with a very nice fiberglass surface. First we used epoxy to penetrate as deep as possible into the remaining rotten wood. Then we pieced in a 1/2" piece of starboard (~8"x18") and epoxy filled with peanut butter strengthened epoxy. After the starboard was solid we then glassed in the corners. We intend to put one more piece of glass across the top to seal everything nicely, although we expect no issues with water penetration at this point.

Last we added a 3/8" 20x24" piece of G10/FR4 to the bottom to serve as a backing plate for all 3 areas of steering hardware. We pre-cut a hole for the rudder shaft and then pilot hole drilled one front and back anchor point. Then we dropped the G10, spread mayonaise strengthened epoxy and clamped it up to dry. The G10 is nicely bonded to the bottom of the fiberglass (left encasing the rotten plywood).

The local machine shop is drilling a larger hole in the deck plate/tiller attachment assembly into which we'll insert new delron bushings. They are also rebushing all 4 sheaves - the 4" bronze idlers and the new edson 3" bronze sheaves. Next weekend we'll do the re-installation of the sheave box, stuffing/bearing, quadrant, idlers, and deck plate. And the rebuild will be complete.......I hope?

3 Photos below: 1: the strengthened epoxied starboard (with bilge breathing MacGyver). 2: add fiberglass mat. 3: G10 while the epoxy kicks

How's it going in Canada?

So MacGyver and I gave up on trying to get all of the rotten wood out. It actually appears as though there are two layers of glass holding 2 layers of wood spanning the distance between the forward and aft cockpit bathtubs (~20x24"). The boat yard said we'd pay more to have them replace the wood than we paid for the boat. The manager also said the strength was in the fiberglass not the wood - don't worry about leaving the rotten wood. We followed their suggestion.

What we did is remove all of the rotten wood we could get to. We were left with a very nice fiberglass surface. First we used epoxy to penetrate as deep as possible into the remaining rotten wood. Then we pieced in a 1/2" piece of starboard (~8"x18") and epoxy filled with peanut butter strengthened epoxy. After the starboard was solid we then glassed in the corners. We intend to put one more piece of glass across the top to seal everything nicely, although we expect no issues with water penetration at this point.

Last we added a 3/8" 20x24" piece of G10/FR4 to the bottom to serve as a backing plate for all 3 areas of steering hardware. We pre-cut a hole for the rudder shaft and then pilot hole drilled one front and back anchor point. Then we dropped the G10, spread mayonaise strengthened epoxy and clamped it up to dry. The G10 is nicely bonded to the bottom of the fiberglass (left encasing the rotten plywood).

The local machine shop is drilling a larger hole in the deck plate/tiller attachment assembly into which we'll insert new delron bushings. They are also rebushing all 4 sheaves - the 4" bronze idlers and the new edson 3" bronze sheaves. Next weekend we'll do the re-installation of the sheave box, stuffing/bearing, quadrant, idlers, and deck plate. And the rebuild will be complete.......I hope?

3 Photos below: 1: the strengthened epoxied starboard (with bilge breathing MacGyver). 2: add fiberglass mat. 3: G10 while the epoxy kicks

How's it going in Canada?