davisr

Member III

It's time to replace my wire-rope halyards. I've read various books and postings on the benefits of converting from wire-rope halyards to all-rope. My question, therefore, is not whether or not I should make the conversion, but how best to make it.

My existing wire is 7 x 19, 5/32 inch. The specs from various manufacturers indicate that the breaking strength of this wire is 2,400 lbs. The rope portion of my halyards consist of 3/8 inch braid. I don't know what type of braid it is, but low-end versions of 3/8 inch braid are rated at 3,000 to 3,700 lbs. Upper end versions (common to halyards) are rated at 5,000 or more pounds. Since the rope portion of the halyard is rated so much higher than the wire portion, it seems that the choice of 3/8 inch rope for 5/32 inch wire (which is common on readymade wire-rope halyard packages from places like West Marine), is based more on the ease that rope this thickness (as opposed to a more narrow rope) gives to the line-handler. Maybe I'm wrong though.

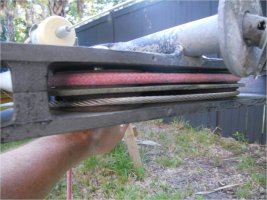

At any rate, based on the numbers I've provided above, it seems that in converting my halyards from wire-rope to all-rope, I could step down a size or two. Sta-Set X, the brand of double braid that I plan to use, rates 1/4 inch rope at 2,700 lbs, and 5/16 inch rope at 4,400. The existing masthead sheaves will handle a 5/16 rope halyard. I've tested them. The only problem, of course, is that the sheaves are V-grooved, made to accommodate the wire portion of the halyard. V-grooved sheaves will create more abrasion and shorten the life of the halyards. Therefore, the most prudent course of action would seem to lead to a replacement of the masthead sheaves - from the V-grooved type to the U-shaped type that are more friendly to all-rope halyards.

Garhauer makes a masthead sheave that is similar in size to the existing sheaves in the E25 masthead. I've order Garhauer hardware before, and I have been impressed with the quality. The MH27 sheave, like all their masthead sheaves, appears to be made of aluminum, and it is reasonably priced (relatively speaking) at $38.40. This is the smallest masthead sheave they make. The specs indicate that it is 3/8 inch wide.

At last my question: Would it be smart, for the sake of line-handling, to make my new halyards 3/8 inch (even though 3/8 inch seems to be overkill from a load-bearing standpoint), or would 5/16 inch be sufficient? It just seems so puny.

Thanks for the help,

Roscoe

E25, cb, #226

Charleston, SC

My existing wire is 7 x 19, 5/32 inch. The specs from various manufacturers indicate that the breaking strength of this wire is 2,400 lbs. The rope portion of my halyards consist of 3/8 inch braid. I don't know what type of braid it is, but low-end versions of 3/8 inch braid are rated at 3,000 to 3,700 lbs. Upper end versions (common to halyards) are rated at 5,000 or more pounds. Since the rope portion of the halyard is rated so much higher than the wire portion, it seems that the choice of 3/8 inch rope for 5/32 inch wire (which is common on readymade wire-rope halyard packages from places like West Marine), is based more on the ease that rope this thickness (as opposed to a more narrow rope) gives to the line-handler. Maybe I'm wrong though.

At any rate, based on the numbers I've provided above, it seems that in converting my halyards from wire-rope to all-rope, I could step down a size or two. Sta-Set X, the brand of double braid that I plan to use, rates 1/4 inch rope at 2,700 lbs, and 5/16 inch rope at 4,400. The existing masthead sheaves will handle a 5/16 rope halyard. I've tested them. The only problem, of course, is that the sheaves are V-grooved, made to accommodate the wire portion of the halyard. V-grooved sheaves will create more abrasion and shorten the life of the halyards. Therefore, the most prudent course of action would seem to lead to a replacement of the masthead sheaves - from the V-grooved type to the U-shaped type that are more friendly to all-rope halyards.

Garhauer makes a masthead sheave that is similar in size to the existing sheaves in the E25 masthead. I've order Garhauer hardware before, and I have been impressed with the quality. The MH27 sheave, like all their masthead sheaves, appears to be made of aluminum, and it is reasonably priced (relatively speaking) at $38.40. This is the smallest masthead sheave they make. The specs indicate that it is 3/8 inch wide.

At last my question: Would it be smart, for the sake of line-handling, to make my new halyards 3/8 inch (even though 3/8 inch seems to be overkill from a load-bearing standpoint), or would 5/16 inch be sufficient? It just seems so puny.

Thanks for the help,

Roscoe

E25, cb, #226

Charleston, SC