Good morning sailors,

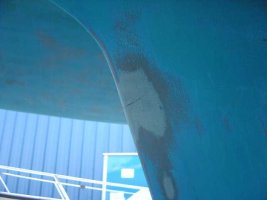

Attached is a photo of the cracks I found in the deep fin keel of my 1980 E38. Has anyone seen this before and have any idea what causes it? Has anyone ever had a keel crack repaired? It took a day or so out of the water, resting on the keel, before I noticed the crack in the paint. The next day it wept some water. When the paint was still on, it hid the second and third cracks on this side. The aft-most crack extends around the radius to the right side, but stops about an inch forward, too. They are still weeping some water. When I first saw the crack in the paint I was hoping for a paint-only problem, but...

The aft crack is 3/4" long. Moving forward, the second crack is 1/2" long and the last one is 1-1/4" long.

The yard ops manager said that many boats have similar conditions but did not elaborate. I think I need to have a keel or structural guy take a look at it. I just don't know who to talk to yet. I may e-mail the PO to ask him about it, too.

Some other interesting, possibly contributing facts.

(1) Before I bought this boat, it sat for ~9 months at a brokers dock at Anacortes, WA, in shallow water. The keel rested in the mud during some low tides and was discolored black up to about 10 inches. The boat also sat in the PO's backyard for several years during his refit and then just resting the year before he sailed it back up here for his last season. He stored it ashore in Anacortes during winters (he cruised it in the Northwest).

(2) While sanding off the black I discovered some amount of filler (looks like epoxy) around parts of the bottom inch or so. Seems like it's been run aground during it's life.

(3) I have touched the bottom with the keel twice since I've owned it. Once in my marina at an extreme low tide with 18' indicated on the depth (at last glance). Just a tap at about 2 knots, probably an old piling or sunken log. The second time was leaving the Port Townsend Boat Haven, right at the entrance, where the guides warn about staying to one side because of a shelf that juts out. Found it. Again just a tap with 5.9' on the depth, at maybe 3 knots. I doubt these two taps caused the problem, but that's alot of momentum, on a long arm.

Sorry to bore you with speculation, but this condition looks to me like it would be caused by flexing the keel from side to side while the bottom of the keel was fixed in place - in mud or on blocks. Is it an indication of improper blocking or a caution against too much time ashore for this type of keel? You E38 folks on the east coast haul out each winter, right?

*** The cracks are in epoxy that encapsulates the keel **** 4/24/05

Cheers and thanks,

Attached is a photo of the cracks I found in the deep fin keel of my 1980 E38. Has anyone seen this before and have any idea what causes it? Has anyone ever had a keel crack repaired? It took a day or so out of the water, resting on the keel, before I noticed the crack in the paint. The next day it wept some water. When the paint was still on, it hid the second and third cracks on this side. The aft-most crack extends around the radius to the right side, but stops about an inch forward, too. They are still weeping some water. When I first saw the crack in the paint I was hoping for a paint-only problem, but...

The aft crack is 3/4" long. Moving forward, the second crack is 1/2" long and the last one is 1-1/4" long.

The yard ops manager said that many boats have similar conditions but did not elaborate. I think I need to have a keel or structural guy take a look at it. I just don't know who to talk to yet. I may e-mail the PO to ask him about it, too.

Some other interesting, possibly contributing facts.

(1) Before I bought this boat, it sat for ~9 months at a brokers dock at Anacortes, WA, in shallow water. The keel rested in the mud during some low tides and was discolored black up to about 10 inches. The boat also sat in the PO's backyard for several years during his refit and then just resting the year before he sailed it back up here for his last season. He stored it ashore in Anacortes during winters (he cruised it in the Northwest).

(2) While sanding off the black I discovered some amount of filler (looks like epoxy) around parts of the bottom inch or so. Seems like it's been run aground during it's life.

(3) I have touched the bottom with the keel twice since I've owned it. Once in my marina at an extreme low tide with 18' indicated on the depth (at last glance). Just a tap at about 2 knots, probably an old piling or sunken log. The second time was leaving the Port Townsend Boat Haven, right at the entrance, where the guides warn about staying to one side because of a shelf that juts out. Found it. Again just a tap with 5.9' on the depth, at maybe 3 knots. I doubt these two taps caused the problem, but that's alot of momentum, on a long arm.

Sorry to bore you with speculation, but this condition looks to me like it would be caused by flexing the keel from side to side while the bottom of the keel was fixed in place - in mud or on blocks. Is it an indication of improper blocking or a caution against too much time ashore for this type of keel? You E38 folks on the east coast haul out each winter, right?

*** The cracks are in epoxy that encapsulates the keel **** 4/24/05

Cheers and thanks,

Attachments

Last edited: