Shankara

Member II

Greetings!

When I purchased my beautiful 1980 Ericson 25+ last year in Portland, the previous owner opened the bilge and said, “Dry, good!” I thought to myself, “Wow! I don’t even know what a bilge is?” It was a strange and fascinating looking part of the boat and I was amazed.

Last winter the bilge was filling up quite fast and needed manual emptying often. I could not figure out how to turn on the electric bilge and it was not turning on by itself. My guess was that it was broken or maybe needed a new fuse but I did not know how those things worked yet. I’m determined though, and am currently learning as much as possible.

I figured I would start with the manual bilge pump installation out in the cockpit. There was a manual bilge pump installed at some point, although only remnants remained. I purchased a new manual bilge and unfortunately the holes did not align so the battle of the bilge began!

I filled the old holes with epoxy and drilled new ones. When I went to run the bilge intake hose down under the sole into the bilge, I realized that I should probably remove the old bilge electrical components and clean out the grime. This meant doing something terrifying to me, removing the electrical switch panel.

Upon removing the panel it was scary as the spaghetti of wires was packed in tight. I’m just learning about marine electrics also. The main thing that scared me was the positive and negative bus bars are floating, not screwed down anywhere.

I made a discovery! The reason why the electric pump did not work was that someone had previously disconnected it.

Perhaps it was disconnected because it was fried due to wires badly connected with electrical tape below the waterline.

I removed the electronic stuff and cut the wire further up the line. Temporarily electrical taped it.

I then soaked the bilge overnight in bilge cleaner and water. I had no idea this little bilge holds 20 gallons! An incredible amount of oily diesel detergent grime was released. I bought some 5 gallon buckets and lids and disposed of it properly with Crescent City harbor maintenance.

I did another scrub, vacuumed it all out, and then noticed a lot of loose fiberglass, resin, and rusty debris. The obvious chunks were scraped out and removed, although I did not want to open any cans of worms, or water, so I was a a bit hesitant to scrape too far.

Before:

After:

Feeling very satisfied with myself for getting this far I decided, it’s time to install this box filter to the bottom of the bilge. But how? I noticed a screw screwed down into the bilge from a PO. Can I screw down into the bilge I thought? Seems questionable at best.

So I asked a friend at the marina. He said no way, never screw into a bilge, because water can slowly corrode into the fabric of the boat through such holes. He suggested I epoxy a piece of wood or plastic to the bilge base to mount the equipment onto.

After showing him a picture of what I was working with, he said I should do some epoxy work within the bilge to fill any cracks, and then paint it with gray bilge paint. Then add a piece of wood or plastic to screw into.

I am planning this week to do the epoxy repair and bilge painting, although I am not sure what this bolt hole looking thing is in the front half of the bilge?

Another fellow sailer here took a look and said, “I’d take a picture of that and post it on that Ericson yacht forum that you are part of and ask them what to do about this.” “It looks like a bolt is missing.“ He also wanted me to ask if anybody knows what these curved metal bands with bolts are? He thought they looked like a newer addition.

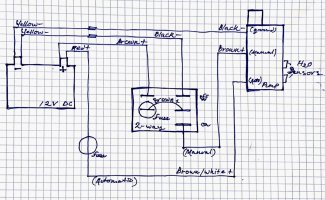

After the bilge is cleaned up and functioning nicely, I plan on wiring in a new electric float and bilge pump, as well as a high water alarm system.

Does anyone here have any insight into the rusty bolt looking part, or have any other comments or suggestions about sealing the bilge or anything else?

Thanks,

Shankara

When I purchased my beautiful 1980 Ericson 25+ last year in Portland, the previous owner opened the bilge and said, “Dry, good!” I thought to myself, “Wow! I don’t even know what a bilge is?” It was a strange and fascinating looking part of the boat and I was amazed.

Last winter the bilge was filling up quite fast and needed manual emptying often. I could not figure out how to turn on the electric bilge and it was not turning on by itself. My guess was that it was broken or maybe needed a new fuse but I did not know how those things worked yet. I’m determined though, and am currently learning as much as possible.

I figured I would start with the manual bilge pump installation out in the cockpit. There was a manual bilge pump installed at some point, although only remnants remained. I purchased a new manual bilge and unfortunately the holes did not align so the battle of the bilge began!

I filled the old holes with epoxy and drilled new ones. When I went to run the bilge intake hose down under the sole into the bilge, I realized that I should probably remove the old bilge electrical components and clean out the grime. This meant doing something terrifying to me, removing the electrical switch panel.

Upon removing the panel it was scary as the spaghetti of wires was packed in tight. I’m just learning about marine electrics also. The main thing that scared me was the positive and negative bus bars are floating, not screwed down anywhere.

I made a discovery! The reason why the electric pump did not work was that someone had previously disconnected it.

Perhaps it was disconnected because it was fried due to wires badly connected with electrical tape below the waterline.

I removed the electronic stuff and cut the wire further up the line. Temporarily electrical taped it.

I then soaked the bilge overnight in bilge cleaner and water. I had no idea this little bilge holds 20 gallons! An incredible amount of oily diesel detergent grime was released. I bought some 5 gallon buckets and lids and disposed of it properly with Crescent City harbor maintenance.

I did another scrub, vacuumed it all out, and then noticed a lot of loose fiberglass, resin, and rusty debris. The obvious chunks were scraped out and removed, although I did not want to open any cans of worms, or water, so I was a a bit hesitant to scrape too far.

Before:

After:

Feeling very satisfied with myself for getting this far I decided, it’s time to install this box filter to the bottom of the bilge. But how? I noticed a screw screwed down into the bilge from a PO. Can I screw down into the bilge I thought? Seems questionable at best.

So I asked a friend at the marina. He said no way, never screw into a bilge, because water can slowly corrode into the fabric of the boat through such holes. He suggested I epoxy a piece of wood or plastic to the bilge base to mount the equipment onto.

After showing him a picture of what I was working with, he said I should do some epoxy work within the bilge to fill any cracks, and then paint it with gray bilge paint. Then add a piece of wood or plastic to screw into.

I am planning this week to do the epoxy repair and bilge painting, although I am not sure what this bolt hole looking thing is in the front half of the bilge?

Another fellow sailer here took a look and said, “I’d take a picture of that and post it on that Ericson yacht forum that you are part of and ask them what to do about this.” “It looks like a bolt is missing.“ He also wanted me to ask if anybody knows what these curved metal bands with bolts are? He thought they looked like a newer addition.

After the bilge is cleaned up and functioning nicely, I plan on wiring in a new electric float and bilge pump, as well as a high water alarm system.

Does anyone here have any insight into the rusty bolt looking part, or have any other comments or suggestions about sealing the bilge or anything else?

Thanks,

Shankara

Last edited: