Here is a link to a quick primer on teak restoration by Don Casey:

http://www.boatus.com/boattech/casey/29.htm

You definitely need to clean the teak before sanding and then varnishing. You mention having used a "restorer." If that is a cleaner and you are happy with it, fine. If not, Casey's link provides info on how to mix up a cleaner.

Varnish offers the most teak protection. Whether it gives the wood a plastic look is I guess a matter of taste.

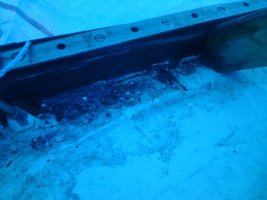

Varnishing your toe rails is going to be a problem so long as you have moisture getting into the rails. It will wick up to the surface and then lift off the varnish. I have seen some claims that a product called "Cetol" is water vapor permeable. I have no first hand experience with Cetol and haven't really researched it but you might want to look into it.

http://www.boatus.com/boattech/casey/29.htm

You definitely need to clean the teak before sanding and then varnishing. You mention having used a "restorer." If that is a cleaner and you are happy with it, fine. If not, Casey's link provides info on how to mix up a cleaner.

Varnish offers the most teak protection. Whether it gives the wood a plastic look is I guess a matter of taste.

Varnishing your toe rails is going to be a problem so long as you have moisture getting into the rails. It will wick up to the surface and then lift off the varnish. I have seen some claims that a product called "Cetol" is water vapor permeable. I have no first hand experience with Cetol and haven't really researched it but you might want to look into it.