peaman

Sustaining Member

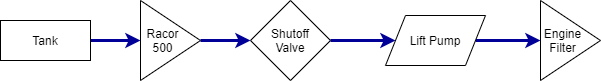

I had just left my slip headed for a couple nights at Block Island. All was normal until I pushed the throttle up to 2000 rpm, and then it was like I throttled back. I found I could run at 1800 rpm, but if I pushed to 2000, same effect. The engine didn’t stop, it just slowed way down.

After checking a few things, I came to suspect my electric fuel lift pump. No clicking when the key was turned “on”. I used a jumper wire to put 12V directly to the hot wire on the pump, and nothing.

M25XPB installed in 2020 with 272 hours. Lift pump is pictured below.

Any comments on the very short life of this pump? Apparently I should order a spare pump along with the replacement. Should I replace the pump in kind, or should I consider some kind of upgrade? Is there no means of manually purging air from this engine (it ran okay at 1800 rpm)?

After checking a few things, I came to suspect my electric fuel lift pump. No clicking when the key was turned “on”. I used a jumper wire to put 12V directly to the hot wire on the pump, and nothing.

M25XPB installed in 2020 with 272 hours. Lift pump is pictured below.

Any comments on the very short life of this pump? Apparently I should order a spare pump along with the replacement. Should I replace the pump in kind, or should I consider some kind of upgrade? Is there no means of manually purging air from this engine (it ran okay at 1800 rpm)?