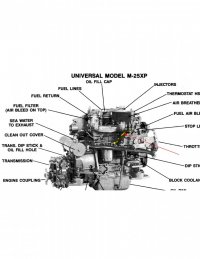

Last week during a cold morning (35 degrees), I went out to my sailboat for a morning (cold but windy) sail. I attempted to start up the engine, normal procedures and I could not get the engine started and eventually my batteries were too low and I ended up plugging in my shore power, charged up my batteries and tried again later in the morning but I was unsuccessful.

This week I investigated what could be wrong. One thought was the glow plugs are original and it has always started a hard at cold temperatures so I ordered new glow plugs, arrived this week, replaced them this morning, and also checked the air flow (cleaned out my air intake can) and I was able to start the engine and I let it run for about 15 minutes to make sure it was running okay. I backed out of the my slip to give it a run for a bit before I went home and as I was turning in the marina, the engine stalled out. I hit the starter button and it started right back up. I put more throttle on it and it started to bogged down and stalled again. This repeated for about 5 times and I eventually coasted back in my slip (took me while as I was feathering the throttle). No throttle and just above idle, it ran fine.

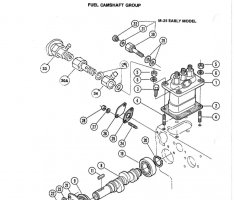

I went down below and I notice my injector bleeder valve was open, maybe 3 turns. I tighten it back down (as per the attached image) and the engine seem to run a little rough so I loosen up the valve nut and saw some bubbles coming out so I bled the bubbles out. I let it run for a while and came back down and the kurl knob was loosen up again. Perhaps the spring or tension in the valve is broken. I can fix it but I had to leave and unfortunately I will not be back for a few weeks so I am left wondering.

If the injector bleeder valve was semi open, would it have this effect on the engine?

Would it allow it to run at low speeds or idle but once you put more load, it bogs down and stalls? But if this allowed air back into the fuel system, why was I able to restart the engine once it stalled out?

I am ruling out the fuel as I just recently replaced the fuel filters and cleaned the tank. I will check all my connections to make sure nothing is obvious.

Thanks!

Patrick

This week I investigated what could be wrong. One thought was the glow plugs are original and it has always started a hard at cold temperatures so I ordered new glow plugs, arrived this week, replaced them this morning, and also checked the air flow (cleaned out my air intake can) and I was able to start the engine and I let it run for about 15 minutes to make sure it was running okay. I backed out of the my slip to give it a run for a bit before I went home and as I was turning in the marina, the engine stalled out. I hit the starter button and it started right back up. I put more throttle on it and it started to bogged down and stalled again. This repeated for about 5 times and I eventually coasted back in my slip (took me while as I was feathering the throttle). No throttle and just above idle, it ran fine.

I went down below and I notice my injector bleeder valve was open, maybe 3 turns. I tighten it back down (as per the attached image) and the engine seem to run a little rough so I loosen up the valve nut and saw some bubbles coming out so I bled the bubbles out. I let it run for a while and came back down and the kurl knob was loosen up again. Perhaps the spring or tension in the valve is broken. I can fix it but I had to leave and unfortunately I will not be back for a few weeks so I am left wondering.

If the injector bleeder valve was semi open, would it have this effect on the engine?

Would it allow it to run at low speeds or idle but once you put more load, it bogs down and stalls? But if this allowed air back into the fuel system, why was I able to restart the engine once it stalled out?

I am ruling out the fuel as I just recently replaced the fuel filters and cleaned the tank. I will check all my connections to make sure nothing is obvious.

Thanks!

Patrick