Ultimately, yes. And since labor costs are a real factor in any decision, choosing the more economical alternative may be wise.

But, for the engineering geeks (self included):

An online calculator will tell you that the "clamping force" of a 1.5" threaded thru-hull torqued to 50 ft-lb equals about 2000 pounds. This stretches the thru-hull (like a spring) and holds the assembly in place regardless of any other means of attaching the assembly to the hull. A soft, flexible sealant (like Seka-flex) is usually used to seal the gaps, but this provides no real additional structural support.

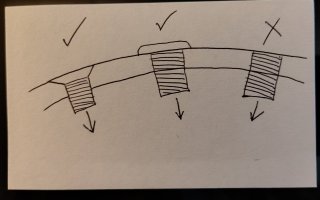

Then, people, liking the idea of "more is better," choose to seal the gaps with epoxy instead, which then does add additional structural support. So far, so good.

But, if you cut the mushroom head off the thru-hull after torquing it down, the epoxy bond then has to pick up the 2000 pounds of force that the mushroom head was providing, which then stresses the epoxy to something like 833psi**. The 'bonding lap-strength' of epoxy is reported to be 870-3625 psi (depending on the materials being bonded).

So, while the remarkable properties of epoxy allow you to get away with cutting off the mushroom head, it's probably better engineering practice to either, (A) leave the mushroom head intact to maintain the clamping force, or, (B) bed the thru-hull in liquid epoxy with only minimal torque applied to the threads (thus reducing the stress on the epoxy when the mushroom head is removed).

For the non-geeks;

Yeah, either way works.

**Note: If the hull is 1/2" thick, a 1.5" dia hole provides 2.4 sq inches of "bonding surface" for the epoxy, and 2000lb / 2.4 sq in = 833 psi.