NOTE: If the ideas below seem reasonable, I'm contemplating a blog article to memorialize the findings. I've seen this forum thread, but didn't want to add to it as the content here is slightly askew from the goal of that thread.

With the number of rain storms coming through the SF Bay area recently, it's given me a good opportunity to see how the bilge pumps on SV Rumour are working -- and not. I realized a while ago that the shower bilge wasn't automatically pumping. No big deal -- water never goes down the shower drain in the floor of the head, so why would that fill up? Turns out with enough rain water down the mast and even without a redirecting gutter at the mast step... lots. Enough that it overfills the shower sump compartment and spills into the main bilge and forward into those ridiculous pockets under the forward cabin sole. The squishy cabin sole in the v-berth was a little unnerving.

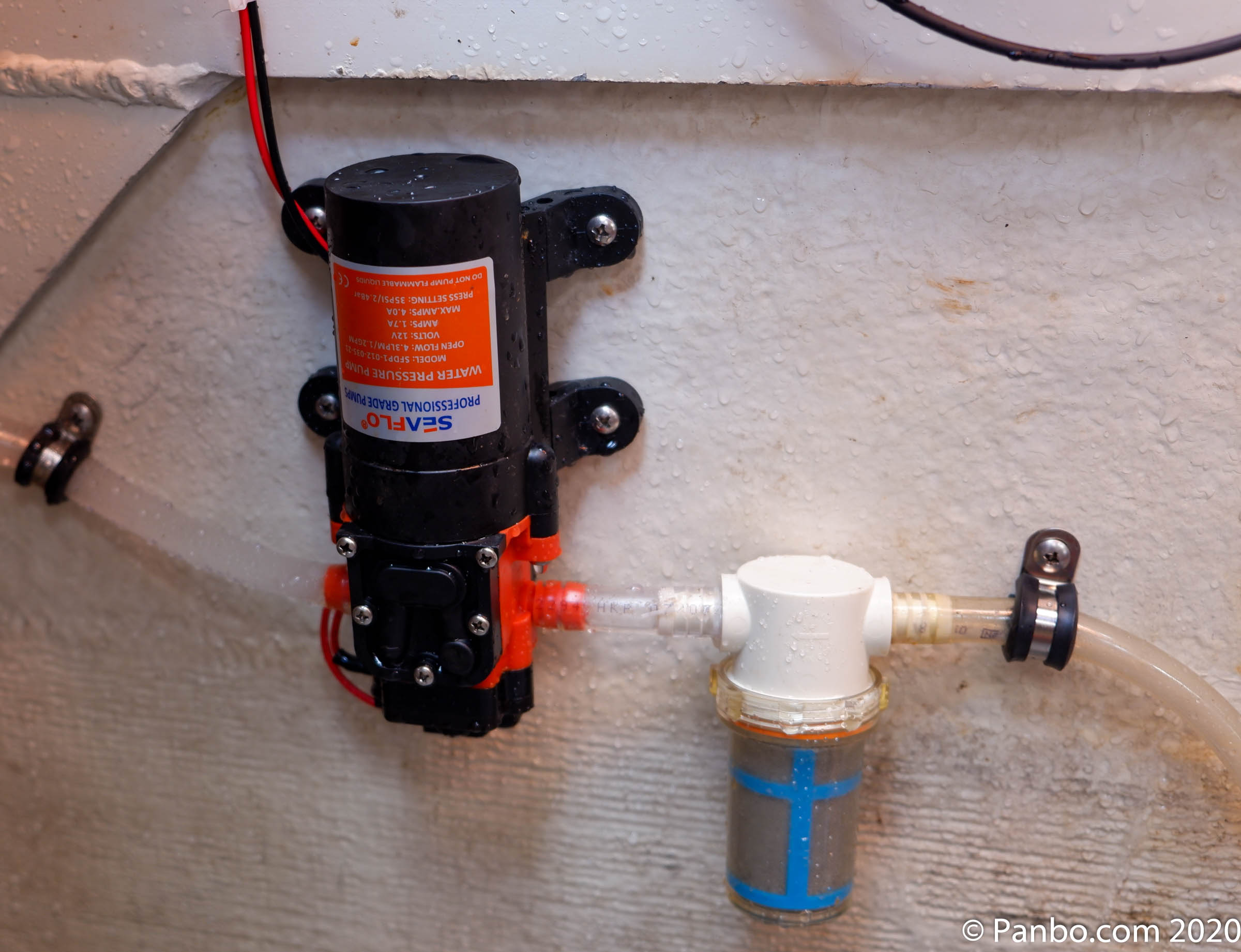

The float switch was broken, but the pump worked when manually triggered. It was an old Rule 400. It would evacuate the shower sump and then all the water left in the red hose would drain back into the sump nearly filling it again (but not quite all the way). That seemed inefficient. Maybe I could improve the system, I thought. I know, a new pump & a check valve!

Ew, and gross.

I collected some parts after reading some threads and blogs around EY.o:

- Non-automatic Rule 800 centrifugal pump

- Water Witch Model 217

- Some hoses, new Scandvik clamps, host connectors

- My wiring tools, heat shrink butt connectors

- JBL speaker to play some shower sump blues

Then I found this thread: https://ericsonyachts.org/ie/threads/factory-original-bilge-pumps-in-32-3.20451/ (wow!)

Then I found this blog article: https://ericsonyachts.org/ie/threads/factory-original-bilge-pumps-in-32-3.20451/ and related comments

So my choices are:

- Leave the check valve in and risk airlock, thus disabling the effect of my handiwork

- Take the check value out and let the water in the discharge hose drain back to the sump

After a beer and a lot of searching on the internet, I came across some random post from a forum far far away which described these small holes on the sides of the newer models of Rule pumps. Or maybe I passed out in the port berth and was visited by an angel. Anyway, these tiny holes were designed to vent enough air so that the pump could defeat airlock. Check it out:

But these tiny holes are covered up with the blue tabs of the strainer which mounts on the bottom of the pump. I'm not sure they're actually doing anything when the strainer is installed. I decided to try a test, so I left the strainer off the pump and put everything back together WITH the check valve. Low and behold, after sucking all the water and some air, the Rule 800 was able to self-vent and pull itself out of airlock. Notice the jets of water directed sideways toward the end of the video clip:

I tested it repeatedly and then left this for a few days and a couple bouts of heavy rain. Went back to the boat and found:

- the shower sump only partially full of water

- the main bilge pump had not fired at all (previously it would have gone off 1-2 times with the same amount of rainfall)

- the forward cabin sole in the v-berth was not squishy (previously it would have been squishy)

So, I present these facts, unaltered and without reservation for peer review: is leaving these tiny holes uncovered a horrible idea? I think I'm getting everything I want... an automatic shower bilge, no runback, no airlock, no potential for dying float switch.

So, I present these facts, unaltered and without reservation for peer review: is leaving these tiny holes uncovered a horrible idea? I think I'm getting everything I want... an automatic shower bilge, no runback, no airlock, no potential for dying float switch.Some extra information:

- Yes, I have anti-siphon loops in the stern near the exit thruhull for the bilge pumps

- Yes, I have a centrifugal Rule pump in the main bilge - contemplating a move to a diaphragm pump though for the main bilge

- Yes, you can try and convince me that a diaphragm pump for both bilges would be better, and you're probably right

But really I want to evaluate the efficacy of The Tiny Hole Theory

- Yes, if I leave it this way I will probably drill a tiny hole in the blue tab and reinstall the strainer