Papidoos56

1973 E32-2

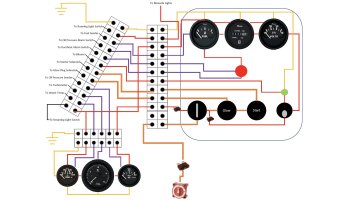

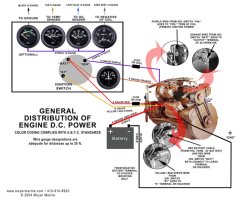

I have an 1973 Ericson E-32. We have been experiencing issues with wiring. Apparently someone miswired the ignition control panel and it keeps shorting out. Most recently I think it toasted the starter. Can anyone: 1) Steer me to a schematic that I can make sense of...or draw one perhaps. 2) Take a photo of the inside of your E-32 panel. 3) Provide me with a schematic of the engine wiring so it can be made right. According to a local wrench the coil is mis-wired, the panel is mis-wired, etc.

DESPERATE!!!

DESPERATE!!!