Parrothead

Member III

If there's interest, I have some material left over and would be happy to send a sample to anyone on this forum who asks.

All EYO members and followers are welcome to join the fun and get to know the people you've met online!

See the link below for login credentials and join us!

(dismiss this notice by hitting 'X', upper right)

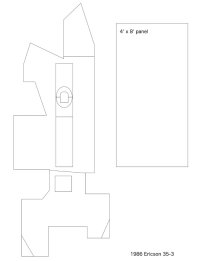

Thanks Christian. That master thread is referenced in post #1 here, and very helpful. I'm trying to keep this to things I haven't found in those posts or are specific to the E35-3.See Also:

Replacement of Cabin Sole [Master Thread]

Unfortunately, my boat is one of the models where Ericson glued down the teak and holly sole. Has anyone ever removed it on a similar boat and how big of a job is it?ericsonyachts.org

If there is a scrap left, I would like one. If not, that's ok. You can message me for address details, and let me pay for postage.If there's interest, I have some material left over and would be happy to send a sample to anyone on this forum who asks.

...

...

Christian,. . .

The extensive floor expansion-gap edge trim--I have that too. Are you going to replace as before? . . .

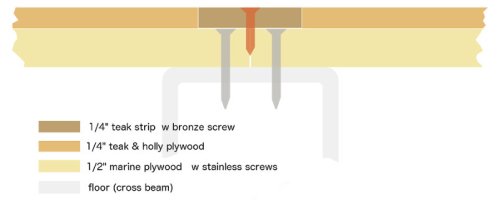

I feel strongly that all the plywood be saturated with penetrating epoxy, esp. the end grain. Underside is constantly wet from condensation if not actual bilge water. . . .

When I replaced the sole in our 34-2 five years ago I used Smiths Penetrating Epoxy on the bottom sides and end cuts of all the panels and have had zero water ingress so far. From my experience once water gets into plywood it seems to be there for life no matter what the wood was treated with.I was going to saturate the plywood sub-sole with penetrating epoxy. Dean isn’t a fan of that because if any water does get into interior wood, it can’t dry out as well. He suggests bilge paint, which I’m contemplating. And I’ve got to go back and read the other related threads here to pick a T&H finish.

. . .

. . .

Look at you two actually sailing! Looks great Jeff. Enjoy the rest of the season.This sole project is turning into The Song That Never Ends.

If I had it to do over again, I would definitely buy 3/4" T&H plywood rather than try to laminate like I'm doing. That process is really something that should be done vacuum bagging and and with way more weight. As it was, I used 250# of playground sand and anything in the garage I thought might have some weight.

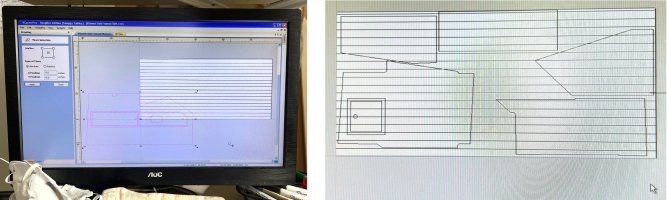

View attachment 47842

It took some finagling to get the right mix of filler and epoxy. It was too thick for some of the first panels and the top sheet didn't settle all the way down. All the panels are glued now and we're cleaning up the old .5" x .75" access panel trim and attaching it.

So, we haven't done any cruising yet, but we have been doing a fair amount of day sailing. We've had friends and family out and given a half dozen people their first time driving a sailboat. It was really important for us to have a boat where we could share our love of boating. Last year we were just putting the boat in the water at this time, so I'm counting this as a win. We're enjoying some vicarious cruising through your posts here.

View attachment 47844 . . . View attachment 47845

Cheers,

Jeff and Donna

That you left it out of your project slipped by me, thinking it never had one. I only gave passing thought to not including it. I had some vague notion that I might need it for access at some point, though really, there isn't much that can be reached in there.Ericson went to some trouble to support that sweep box, which I've always thought was a clever detail. I didn't put mine back in because these days I use a battery hand vac.

For thread integrity, here is my E381 sole replacement project.