Yes, the (horizontal) bolt that holds the cast aluminum gooseneck to the fitting on the mast should be snug and checked regularly.

Also, the pintle, which allows lateral swing. Looseness of either can create unwanted forces and subsequent damage to the components.

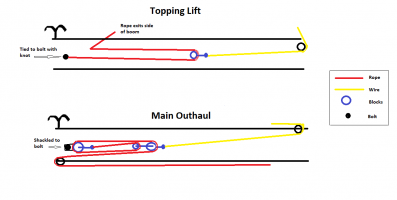

The weak point of our goosenecks is the connection shown below, in which the ear of the casting was worked by loose fittings and eventually failed. That particular failure is not so easy to fix, old aluminum is difficult to weld, and a replacement gooseneck is $800 or so and a long wait from Rigrite (there are better solutions).

Note also in the photo that the stainless connector has sagged as result of the gudgeon being bent down. This condition meant that the swing of the boom was impeded--the mated fittings could snag where the U-shaped pintle housing met the lower gudgeon.

With reef lines and other stuff led back to the cockpit, there is more strain on the cast ears of the gooseneck than its designer probably intended back in the day.

The gooseneck is a critical part that rewards recurring attention.