I spent too much time and money getting the wrong sized gaskets twice and eventually gave up and bedded them entirely in Dow 795. I used some little bits of the original gasket as spacers. Still going strong 6 years on. It will be a real nightmare if I ever have to redo them though!

I finished the fixed portlights this past Spring. I'm finally putting some pictures up. This is how I used bigd14's method to reassemble them.

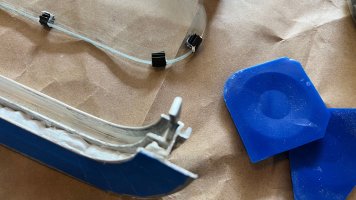

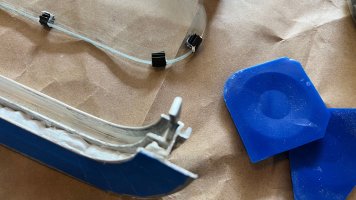

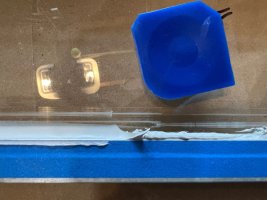

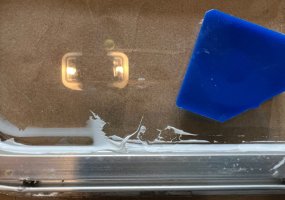

One of the original gaskets was cut into small pieces to float the lens in the frame.

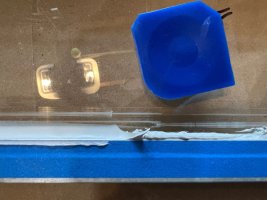

A generous bead was laid into the the frame channel.

The frames went together with moderate pressure from a bar clamp. For our frames I didn't need to build a custom fixture.

After the frame was assembled and the two bridge connectors were screwed I pumped some caulk into the joints were there are some cleverly placed holes.

The spacers rode up in places so I pushed them down, allowing for a good caulk bead front and back..

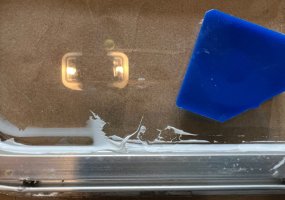

On the outer surfaces I used a large diameter for the fillet.

A smaller diameter was used on the inside fillet.

After a day of cure, a razor scraper took off the overflow fairly easy. In a do over, I might have masked the glass too. But that's probably as tedious as scraping.

I'd just assumed all fixed portlights were made the same and was surprised to see that

@peaman 's 1987 E32-3 had one piece frames. How they made those is beyond me. And how to rehab them is even further beyond. It appears to be the same extrusion and gasket.

post #89

https://ericsonyachts.org/ie/threads/replacing-fixed-windows-research-master-thread.9603/post-170015

My original intention was to reuse the gaskets but I decided that even though they seemed good now, they were likely to degrade in elasticity and seal. I hope I never have to take these apart again because this Dow stuff will be a bear to get off.

For installation in the cabin wall I used 3M 4000 UV. If I'd know then about the Dolfinite that peaman used, I might well have used that.

I've got three intact glazing gaskets if anyone wants them.

Jeff