1. I was helpfully told: Mark your hull where you want the the sling straps to go, so you won't damage any underwater appendages. Consult Saiboatdata.com if necessary for a model drawing.

2. My 'project manager' at KKMI, the boatyard at which I will haul out suggested pulling the cotter pins, loosening my shrouds and I labelled them for good measure. I also marked with yellow tape the adjusted turnbuckle locations at which I started. I then backed off each cable about 1/4-1/2" on the turnbuckle. There were some pre-occupying pops and twangs as the cables loosened.

In theory this prep work will cost me less $ in crane time, though I expect I won't see the actual hours until I get my final bill. Probably just made life easier for the boatyard workers. But this way, I have to rely on the careful organization of the yard dudes, a little less.

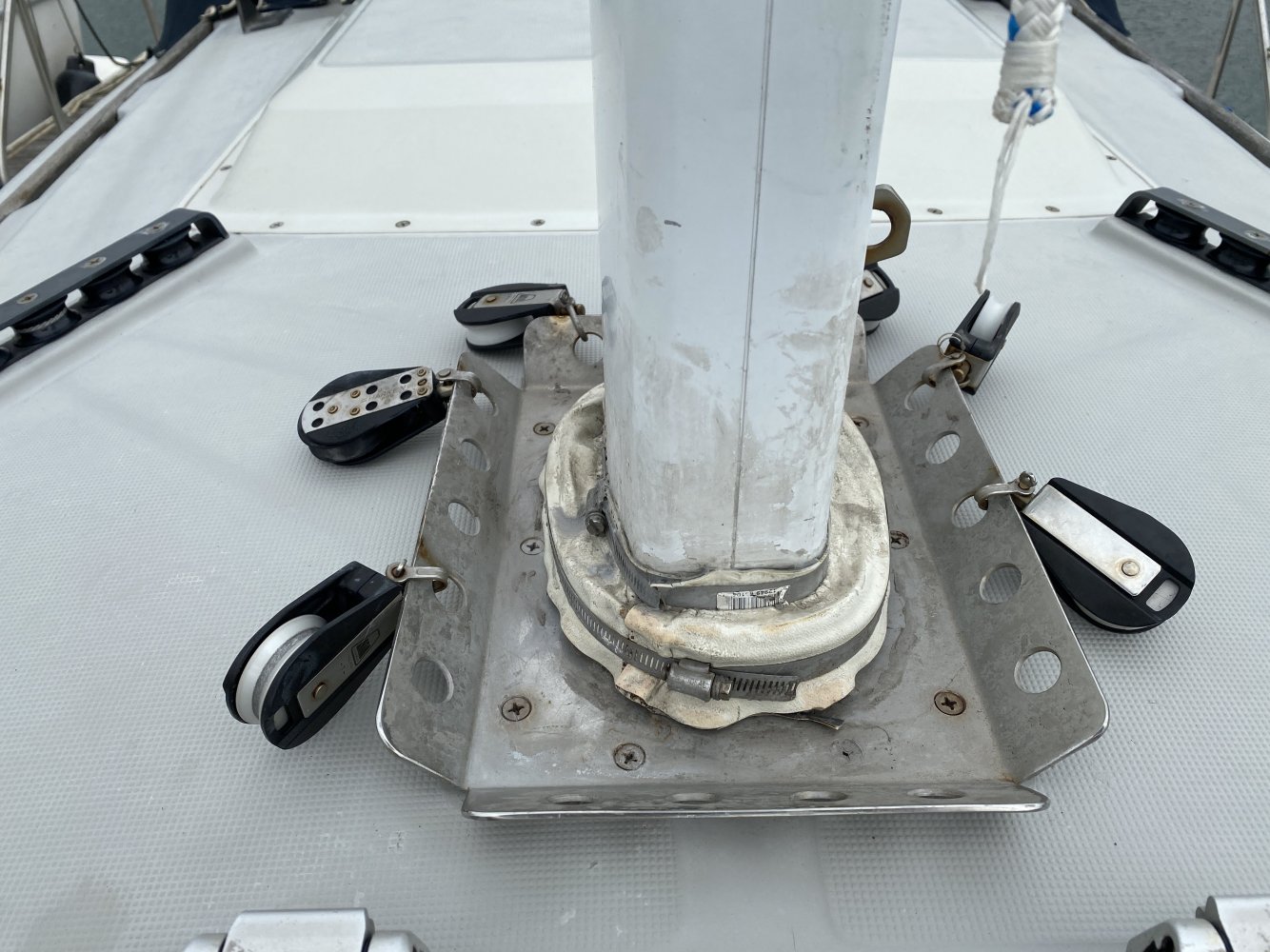

3. Open up the mast boot and ensure it can be raised freely from the hull. Despite the weathered (withered?) appearance, this has never leaked:

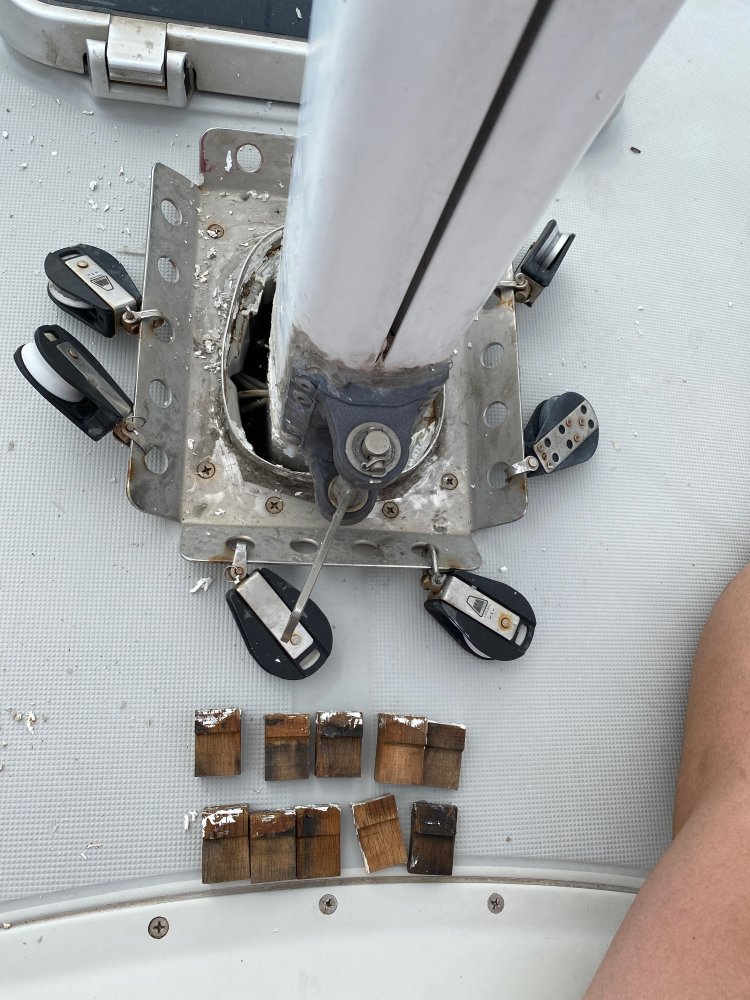

4. Oh, that's why it never leaked. It's "possible" that water intrusion around the mast was a problem with which a prior owner had some experience. That's a couple of tubes of silicone in the space between the mast and the partner::

5. Remove the gunk and set aside some teak shims found amidst the product.

6. Inside, detach the custom dining table:

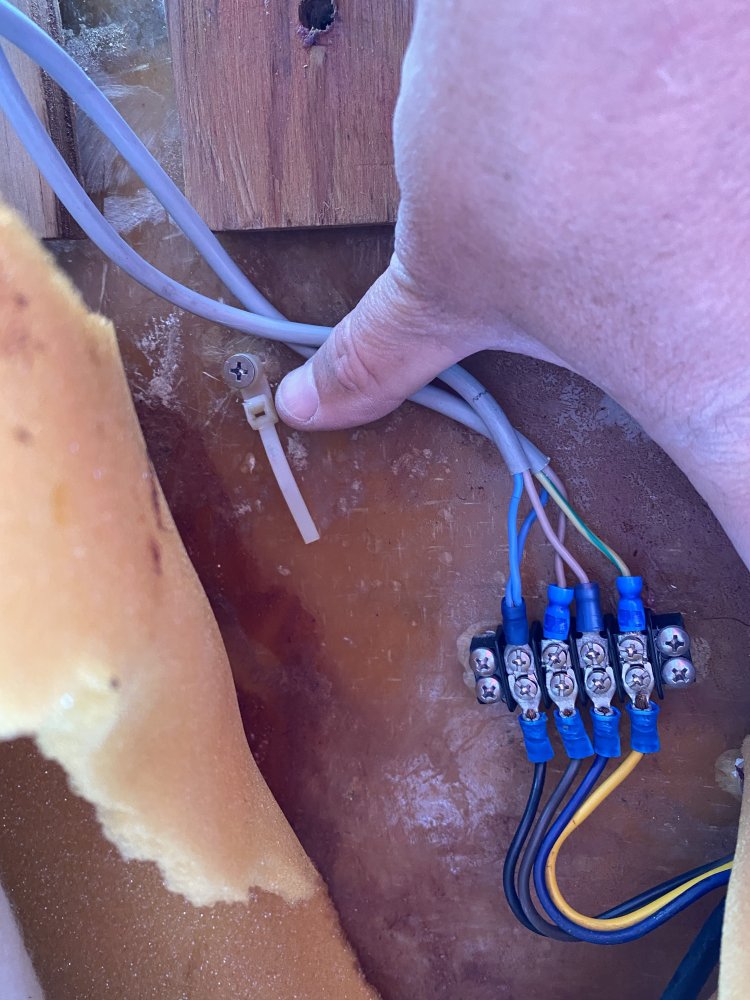

7. Unzip the headliner, detach the wires, and unhook the keeper downhaul cable attaching the mast to the cabin top. Pictured are the DC power wires for the lights. Separately there were two coaxial cables. On the 32-200, there is a nice extra void on port side to permit the wide-ish coaxial plugs to pass. Good thinking, Ericson.

I think it's close to being ready to go. The plan is to drive across the bay from Sausalito to Richmond, then do additional work loosening shrouds after I am sitting in the canal waiting for my appointed crane time.

2. My 'project manager' at KKMI, the boatyard at which I will haul out suggested pulling the cotter pins, loosening my shrouds and I labelled them for good measure. I also marked with yellow tape the adjusted turnbuckle locations at which I started. I then backed off each cable about 1/4-1/2" on the turnbuckle. There were some pre-occupying pops and twangs as the cables loosened.

In theory this prep work will cost me less $ in crane time, though I expect I won't see the actual hours until I get my final bill. Probably just made life easier for the boatyard workers. But this way, I have to rely on the careful organization of the yard dudes, a little less.

3. Open up the mast boot and ensure it can be raised freely from the hull. Despite the weathered (withered?) appearance, this has never leaked:

4. Oh, that's why it never leaked. It's "possible" that water intrusion around the mast was a problem with which a prior owner had some experience. That's a couple of tubes of silicone in the space between the mast and the partner::

5. Remove the gunk and set aside some teak shims found amidst the product.

6. Inside, detach the custom dining table:

7. Unzip the headliner, detach the wires, and unhook the keeper downhaul cable attaching the mast to the cabin top. Pictured are the DC power wires for the lights. Separately there were two coaxial cables. On the 32-200, there is a nice extra void on port side to permit the wide-ish coaxial plugs to pass. Good thinking, Ericson.

I think it's close to being ready to go. The plan is to drive across the bay from Sausalito to Richmond, then do additional work loosening shrouds after I am sitting in the canal waiting for my appointed crane time.