Retired from newspapers and television, currently sailing Thelonious II, a 1984 Ericson 381.

Three sewing machines compared (video). Select "Watch on YouTube" for high resolution.

Why bother to learn to sew?

Sewmanship, as Popeye and I likes to call it, is a manly art dating way back. On the other hand, a stock sail cover on the Internet doesn’t cost much more than the Sunbrella fabric does retail - - and Lord Nelson didn’t make his own hats. However, I found that driving around to various canvas shops with my little sketch in hand meant being perceived as a hapless bozo for 10 bucks a grommet. One budget tailor explained patiently to me how difficult it is to make a hem in Sunbrella. I noticed his wife smiling into her soup [because it’s not true; any machine can easily make a hem in Sunbrella]. I did make my own hatch covers a few years ago on my teenage daughter’s sewing machine. They looked OK from 20 feet. I didn’t know what I was doing and like a rented horse the little sewing machine would immediately take a crap and head for the barn.

But that was before I was the last guy alive to discover Sailrite. Sailrite.com is in the business of teaching us how to sew so we’ll buy materials from them. As a result of this business model, just about every trade secret of the canvas worker’s art is given away free in their hundreds of streaming instruction videos. But the real lesson is that sewing stuff for the boat turns out to be as enjoyable as varnishing, changing engine oil and all the other things we do for reasons that are not always logical and for which we could often simply pay.

A fellow with a sewing machine suddenly notices the canvas on every boat around him -- the semiflat-felled seams, the triple stitching, the taut fit (or not), the placement of darts, the color, the material, the hardware, the design. There’s a lot of cloth on a boat besides the sails. The bunk upholstery, line bags, sail bags, ice bags, sunshade, wind funnels, boson’s chair, dinghy tarp, curtains, and all the covers for teak, varnish, fenders, pedestal, jib, main and lifebuoy. All need ongoing repair or replacement. Remaining uninformed for the rest of my days as to how to make a simple winch cover seemed silly. How hard can it be? Only one way to find out.

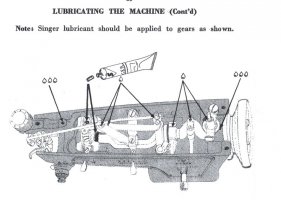

Sewmanship starts with a sewing machine. There are many choices, but I wound up with a 1963 Singer 237. This model is often cited as “good enough” by those who’ve gone before. The 237 is a home machine with an excellent manual that begins, “Everything for the woman who sews.” Hats off to those ‘60s women. The machine weighs 35 pounds, has all metal gears, and requires weekly oiling at 12 separate points.

At $100-$200 online, it is one of the most complicated and well made machines I’ve ever owned. The main difference between a metal-gear home machine and a new $800-$2000 walking-foot sailmakers’ machine is the length of the straight stitch. The 237 does about an eighth of an inch; the real thing can do three-eighths or more, which is what you usually see on a sail cover. The other difference is that a Singer 237 can only stitch comfortably through about four layers of Sunbrella (the Speedy Stitcher Sewing Awl is a good workaround). Real power requires a flywheel, which the 237 doesn’t have but the sailmaker models do.

....

....

Sewing machines send the threaded needle down to a shuttle that returns a second thread from the bobbin. When all is working well the result is a chattering high-speed stream of perfect stitches that, with the 237, can be straight or zigzag. To lock a stitch you just reverse for half an inch. For most outdoor fabric a #18 needle is used, with UV resistant V-92 polyester thread. This stuff is so strong you could hang from the ceiling on it, and it spools vertically off big 250-yard spools.

It took me a week to get confident with basic sewing. Many times I Googled my problems: stitch not tight, machine jams with nest of bobbin thread below, fabric puckering, “machine jams with double threads”, needle bends, and so on. In the end, all my problems, even the most persistent, were caused by lack of experience. “Something wrong with the machine” was never the real issue. The issue was new guy teaching himself to sew. With a family member who already knows how, success would come faster.

For me, an eBay all-metal-gears home machine turned out to be quite satisfactory for the work intended, which doesn’t include making sails. I spent about $150 on the 237 ($50 more for shipping; they’re heavy) and chose what I thought was a reputable online company that promised fully refurbished products. It would be nice to have a walking-foot model capable of sewing through 10 layers of cloth. I may spring for one yet.

Sewmanship 1--the Sewing Machine

Sewmanship 2--Covers for Dinghy, Hatches, Pedestal, Mainsail

Sewmanship 3--Cockpit Shade, Main Hatch Cover, Interior Upholstery

Sewmanship 4--Line Bags, Seat Locker, Grab Rail Covers

Sewmanship 5--Weather Cloths

Why bother to learn to sew?

Sewmanship, as Popeye and I likes to call it, is a manly art dating way back. On the other hand, a stock sail cover on the Internet doesn’t cost much more than the Sunbrella fabric does retail - - and Lord Nelson didn’t make his own hats. However, I found that driving around to various canvas shops with my little sketch in hand meant being perceived as a hapless bozo for 10 bucks a grommet. One budget tailor explained patiently to me how difficult it is to make a hem in Sunbrella. I noticed his wife smiling into her soup [because it’s not true; any machine can easily make a hem in Sunbrella]. I did make my own hatch covers a few years ago on my teenage daughter’s sewing machine. They looked OK from 20 feet. I didn’t know what I was doing and like a rented horse the little sewing machine would immediately take a crap and head for the barn.

But that was before I was the last guy alive to discover Sailrite. Sailrite.com is in the business of teaching us how to sew so we’ll buy materials from them. As a result of this business model, just about every trade secret of the canvas worker’s art is given away free in their hundreds of streaming instruction videos. But the real lesson is that sewing stuff for the boat turns out to be as enjoyable as varnishing, changing engine oil and all the other things we do for reasons that are not always logical and for which we could often simply pay.

A fellow with a sewing machine suddenly notices the canvas on every boat around him -- the semiflat-felled seams, the triple stitching, the taut fit (or not), the placement of darts, the color, the material, the hardware, the design. There’s a lot of cloth on a boat besides the sails. The bunk upholstery, line bags, sail bags, ice bags, sunshade, wind funnels, boson’s chair, dinghy tarp, curtains, and all the covers for teak, varnish, fenders, pedestal, jib, main and lifebuoy. All need ongoing repair or replacement. Remaining uninformed for the rest of my days as to how to make a simple winch cover seemed silly. How hard can it be? Only one way to find out.

Sewmanship starts with a sewing machine. There are many choices, but I wound up with a 1963 Singer 237. This model is often cited as “good enough” by those who’ve gone before. The 237 is a home machine with an excellent manual that begins, “Everything for the woman who sews.” Hats off to those ‘60s women. The machine weighs 35 pounds, has all metal gears, and requires weekly oiling at 12 separate points.

At $100-$200 online, it is one of the most complicated and well made machines I’ve ever owned. The main difference between a metal-gear home machine and a new $800-$2000 walking-foot sailmakers’ machine is the length of the straight stitch. The 237 does about an eighth of an inch; the real thing can do three-eighths or more, which is what you usually see on a sail cover. The other difference is that a Singer 237 can only stitch comfortably through about four layers of Sunbrella (the Speedy Stitcher Sewing Awl is a good workaround). Real power requires a flywheel, which the 237 doesn’t have but the sailmaker models do.

Sewing machines send the threaded needle down to a shuttle that returns a second thread from the bobbin. When all is working well the result is a chattering high-speed stream of perfect stitches that, with the 237, can be straight or zigzag. To lock a stitch you just reverse for half an inch. For most outdoor fabric a #18 needle is used, with UV resistant V-92 polyester thread. This stuff is so strong you could hang from the ceiling on it, and it spools vertically off big 250-yard spools.

It took me a week to get confident with basic sewing. Many times I Googled my problems: stitch not tight, machine jams with nest of bobbin thread below, fabric puckering, “machine jams with double threads”, needle bends, and so on. In the end, all my problems, even the most persistent, were caused by lack of experience. “Something wrong with the machine” was never the real issue. The issue was new guy teaching himself to sew. With a family member who already knows how, success would come faster.

For me, an eBay all-metal-gears home machine turned out to be quite satisfactory for the work intended, which doesn’t include making sails. I spent about $150 on the 237 ($50 more for shipping; they’re heavy) and chose what I thought was a reputable online company that promised fully refurbished products. It would be nice to have a walking-foot model capable of sewing through 10 layers of cloth. I may spring for one yet.

Sewmanship 1--the Sewing Machine

Sewmanship 2--Covers for Dinghy, Hatches, Pedestal, Mainsail

Sewmanship 3--Cockpit Shade, Main Hatch Cover, Interior Upholstery

Sewmanship 4--Line Bags, Seat Locker, Grab Rail Covers

Sewmanship 5--Weather Cloths