Prairie Schooner

Jeff & Donna, E35-3 purchased 7/21

Hi Ray,This looks a little pink at the top. I might have someone with metal expertise take a look at it before reinstalling it. This might argue for a disc zinc on the strut. Is this bonded to something? Bonding is controversial, I am just asking for my education, not advocating.

Thanks for the input. Yes, there is a little corrosion up there.

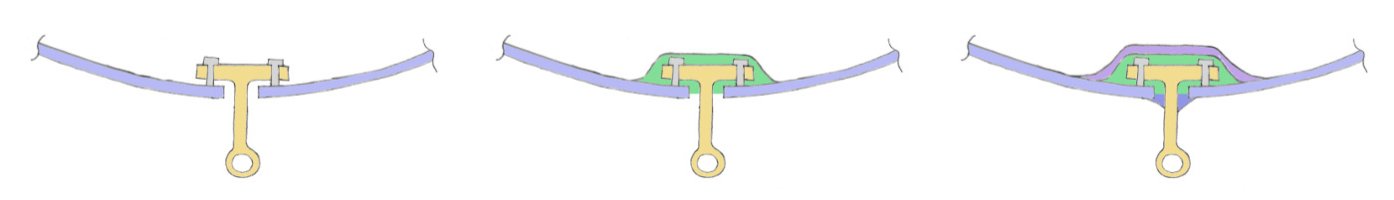

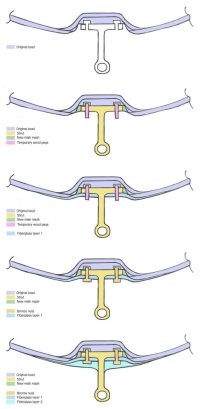

This video shows the reason we are rebedding the strut. It was one of the things the surveyor called out when we bought the boat last fall. Inside the boat, the top of the strut was (is still) completely covered with glass and not bonded.

Salt water was getting up in there, to raw bronze, and this surface was near the SS bolts. I'm thinking these conditions allowed the corrosion. When I reinstall the strut the upper portion will be sealed in with epoxy. The exposed area of the strut will be covered with PropSpeed. I'm also leaning toward using bronze nuts. With these measures I'd kinda ruled out an anode or bonding on the strut this go-round, but am still open to those. I learn a little more with each comment here.

I'm going to talk to a local marine fabricator about putting in the new cutless bearing. I'll ask them about the corrosion, too.

J