mherrcat

Contributing Partner

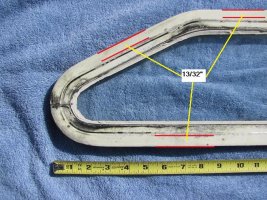

Here are a couple of additional pics, one of another view of the interior of the cutout and one of all the sealant that was on the windows when I pulled them.

I'm not sure what the other white sealant is. It wasn't as stretchy as silicone. A friend thought it might be 5200, but I haven't ever worked with it so I didn't know.

I'm not sure what the other white sealant is. It wasn't as stretchy as silicone. A friend thought it might be 5200, but I haven't ever worked with it so I didn't know.