Kind of summarizes most of youtube, doesn't it?That guy in that video gets and E for effort & enthusiasm, but flunks in understanding (at least on camera) what is really needed to address the root cause of his problem.

-

Untitled Document Join us on March 28th, 7pm EDT

for the CBEC Virtual Meeting

EY.o March Zoom Meeting

All EYO members and followers are welcome to join the fun and get to know the people you've met online!

See the link below for login credentials and join us!

(dismiss this notice by hitting 'X', upper right)

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Deck Repair, Injectadeck and Options [Master Thread]

- Thread starter wynkoop

- Start date

Ah, gentlemen of quick persuasion: YouTube has taught me everything I know, from the fingerings of Django Reinhardt to the arguments of Noam Chomsky, the repair of my gas clothes dryer, leaking dishwasher surfactant chamber and diesel engine injectors, as well as revealing European procedures for the thermite welding of railroad tracks and just exactly how a Russian lawyer bushcrafts his cabin in the woods.

I am much the better for it, and considerably more informed about the Battle of Midway than ever before.

I am much the better for it, and considerably more informed about the Battle of Midway than ever before.

Irresistible. A little off topic from Injectadeck, but still--irresistible!

gargrag

Member II

I'm planing to cut the fiberglass from inside, remove all the rotten core, glue the fiberglass layer again, and then fill the void with injectadeck. The other option I'm considering is instead of injectadeck, using this https://compositeenvisions.com/product/proset-expanding-epoxy-foam-resin-1942/ epoxy foam.

I'm still thinking about it, but will update in case it helps anyone else

I'm still thinking about it, but will update in case it helps anyone else

You may find that some of the fiberglass won't come off cleanly. Or if it does it means you haven't removed enough area to get back to solid core. I did a similar job from underneath on the side decks but used 1/2 inch balsa core material from Jamestown Distributors along with 1/2 G10 plates under deck fittings. As boat projects go it was technically easy, but quite messy. Line everything with plastic.glue the fiberglass layer again,

Springy Side Decks- Reinforce?

I'm in the process of correcting core damage to the side decks, from below. The starboard side is complete, but the port side remains. I'm loathe to remove the galley so I am limiting my repairs to the easily accessible areas, although I suspect the water damage does include the inaccessible...

Mr. Scarlett

Member III

Yes, PPE and protecting the interior are very important. Having done this I don't envy you one bit.

I also used balsa since it seemed to have held up for at least 40 years. Mapping out each area with a 1/8" drill bit and a Sharpie. As mentioned above, it's doable but messy. I wouldn't get too hung up on saving the old skin, this could be a great time to learn about vacuum bagging. If you can do it upside down, you can do it anywhere!

I have no experience with injectadeck other than videos lamenting its use when it comes time to do the job over with a solid core. As far as expanding foam goes, again no experience but it seems to me that one could end up with a bigger project than what they started with if they weren't careful. If I had to do it again I'd use balsa, (there's a chance the right person could talk me into foam), and perhaps plywood or G10 in a few strategic places.

Mind you these are just opinions, I'm sure there's any number of cases where the alternatives have worked out just fine. Good luck!

I also used balsa since it seemed to have held up for at least 40 years. Mapping out each area with a 1/8" drill bit and a Sharpie. As mentioned above, it's doable but messy. I wouldn't get too hung up on saving the old skin, this could be a great time to learn about vacuum bagging. If you can do it upside down, you can do it anywhere!

I have no experience with injectadeck other than videos lamenting its use when it comes time to do the job over with a solid core. As far as expanding foam goes, again no experience but it seems to me that one could end up with a bigger project than what they started with if they weren't careful. If I had to do it again I'd use balsa, (there's a chance the right person could talk me into foam), and perhaps plywood or G10 in a few strategic places.

Mind you these are just opinions, I'm sure there's any number of cases where the alternatives have worked out just fine. Good luck!

gargrag

Member II

Yes, PPE and protecting the interior are very important. Having done this I don't envy you one bit.

I also used balsa since it seemed to have held up for at least 40 years. Mapping out each area with a 1/8" drill bit and a Sharpie. As mentioned above, it's doable but messy. I wouldn't get too hung up on saving the old skin, this could be a great time to learn about vacuum bagging. If you can do it upside down, you can do it anywhere!

I have no experience with injectadeck other than videos lamenting its use when it comes time to do the job over with a solid core. As far as expanding foam goes, again no experience but it seems to me that one could end up with a bigger project than what they started with if they weren't careful. If I had to do it again I'd use balsa, (there's a chance the right person could talk me into foam), and perhaps plywood or G10 in a few strategic places.

Mind you these are just opinions, I'm sure there's any number of cases where the alternatives have worked out just fine. Good luck!

any material on how to approach core replacement woth vacuum bagging from the inside?

I used vacuum bagging on my port side repair, but decided not to use it on the starboard side. Vacuum bagging requires a perfect seal for it to work and you can only achieve that by sealing against the top skin (assuming you are going from below). If you try to seal against the bottom skin, the air will travel through the good core and escape through the staple holes. On the port side, I installed the bulk of the new core with vacuum, then filled in the space between the new core and old core using extendable drywall sanding poles to push up. At the end of the day, our boats aren't super light racers, so a little extra resin between the outer skin and new core isn't going to hurt anything. Here's a some more detail on my experience:

ericsonyachts.org

ericsonyachts.org

E25+ - New Core...the wrong way I'm told

The first step with replacing the core was identifying justhow much core was rotten. As you canexpect, the affected area was greater than I initially expected. The void along the edge and between the topskin and balsa created by not spreading...

gargrag

Member II

yo convinced me to go with the proper repair.I used vacuum bagging on my port side repair, but decided not to use it on the starboard side. Vacuum bagging requires a perfect seal for it to work and you can only achieve that by sealing against the top skin (assuming you are going from below). If you try to seal against the bottom skin, the air will travel through the good core and escape through the staple holes. On the port side, I installed the bulk of the new core with vacuum, then filled in the space between the new core and old core using extendable drywall sanding poles to push up. At the end of the day, our boats aren't super light racers, so a little extra resin between the outer skin and new core isn't going to hurt anything. Here's a some more detail on my experience:

E25+ - New Core...the wrong way I'm told

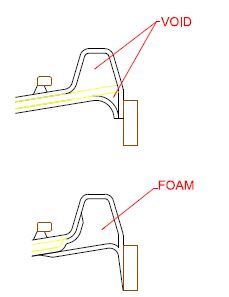

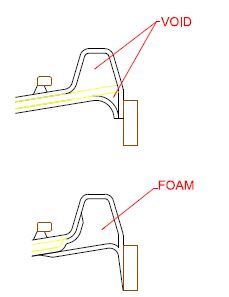

The first step with replacing the core was identifying justhow much core was rotten. As you canexpect, the affected area was greater than I initially expected. The void along the edge and between the topskin and balsa created by not spreading...ericsonyachts.org

I think. I'll plan for the end of the season, @trickdhat did you do this repair with the boat on the water and the mast stepped?

Yes, I cut into the laminate while it was on the hard, but the rest of the job was in the water. The Mast was up the whole time.yo convinced me to go with the proper repair.

I think. I'll plan for the end of the season, @trickdhat did you do this repair with the boat on the water and the mast stepped?

gargrag

Member II

@trickdhat gave me the last push to go ahead and do a proper repair on my rotten core, Has anyone recently bought balsa core? any recommendation ?

I purchase most of my supplies from these guys:

fiberglasssupply.com

fiberglasssupply.com

They are local to me, but it's actual cheaper to ship than it is to drive and they're only 45 minutes Away. They also offer classes, so they're really helpful.

Fiberglass Supply

Supplier of carbon fiber fabrics, fiberglass, epoxy resins, core materials, polyester resins, surfboard blanks and other supplies for working with composites.

They are local to me, but it's actual cheaper to ship than it is to drive and they're only 45 minutes Away. They also offer classes, so they're really helpful.

I purchased most of my recore materials from Jamestown Distributors.