Alan Gomes

Sustaining Partner

Congrats! Glad you didn't take my advice!

All EYO members and followers are welcome to join the fun and get to know the people you've met online!

See the link below for login credentials and join us!

(dismiss this notice by hitting 'X', upper right)

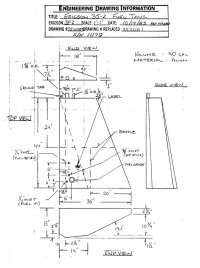

Jeff, it's just a single boat buck! I actually think you're getting a good deal, mine was $750 for a 19 gallon aluminum tank in 2016...We got the quote. $1150. Gulp. - But, we're going to proceed. "The bends are rather complex." This price includes inspection ports. .125 aluminum.

The vertical float on a spiral strip is what I'm looking at Christian. I wondered if it would get stuck more than the floating arm style. Have you had good experience with it?The floating-arm style gauge I bought wouldn't fit in my boat because the arm hit a baffle. I went with a similar model in which the float rises and falls vertically, and doesn;t need "room."

Before ordering, probably wait to have the tank in hand, since depth of tank and location of baffles can matter.

$1.15BB sounds a lot better, doesn't it? (Do I recall correctly, it's Doug?) And with your price, I feel a little less bad about our quote.Jeff, it's just a single boat buck! I actually think you're getting a good deal, mine was $750 for a 19 gallon aluminum tank in 2016...

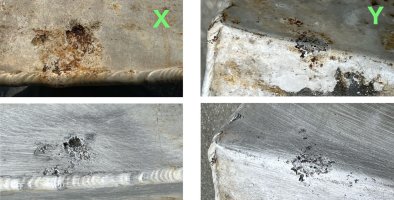

After I had it made and installed I thought I should have specified a drainage port at the front bottom of the tank so I could easily drain any sludge or water out. I'm not sure if this is up to ABYC spec but I would certainly draw a little sample out every so often if I had such a thing.