I just spent some tedious hours changing out the old ATF in our '88 Hurth model 50 trans. The top where the fill/dip stick fitting lives is visible only when both bolts that hold the heat exchanger bracket are removed and the HE is moved slightly to one side. Then I can get a 17 mm socket with an extension on it and use a short handle ("stubby" ratchet to turn it. Luckily the original alum. washer stays on it - pressed on just at the top of the threads, looks like.

The drain plug (17 mm) is more challenging. At least that's one word for it. Cannot see it but can feel it. As before I push a cheap alum. "throw away" pan under the engine from the front. Have to bend the pan (kind of a short sided loaf pan configuration) and then straighten it out once under and push it to the back.

No room for a socket with ratchet. Closed end wrench works, and patience. Hard to put much torque on it reaching way under at an odd angle.

Occasional swearing helps. Once the plug is out I notice that last year there was no washer (never came with one from the PO, if I recall) and I had wrapped a little teflon tape around the base of the threads. Works, but there is some tiny bit of lube seepage, too.

Decided to find a proper washer. The stock alum. washer certainly might be found at the local We$terbeke dealer, but perhaps there's another way...

I recall that I used a special washer to re-seat the banjo fitting under our engine pan drain several years ago. It had a sort of O ring with metal around it. Never a leak since.

I take the metric plug bolt over to Oil Filter Service, where they have a zillion kinds of hoses, filters, and fittings.

Fellow sez "hmmmm" and heads back to a large bank of small drawers.

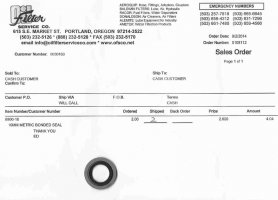

He returns soon with a "16 mm metric bonded seal". it is a snug and perfect fit over the threads, against the base of the plug. Not expensive by boating standards so I buy two.

To me this is better because unlike a "rubber" washer no matter how hi-tek the compound, tightening it will not force the O ring part out of the interface. (I was worried about putting an alum. washer back in and having it seep. ATF is kinda like diesel - it will seep thru very tiny places.)

It all goes back together, and with the normal (+ or -) 10 fl. oz of synthetic ATF added, no drips. I used a plastic straw taped to the base of a small funnel to pour the oil in.

Lordy, it's hard to see the level on the bottom of that dip stick. ATF is red, but when viewed thinly, it is darned near invisible. Have to check and re-check and carefully roll the dip stick tube on a dry piece of paper towel to "read" it.

As for the drained old ATF, it looked as translucent as the day it was put in there, almost 200 hours and a year ago. What with about 2200 total hours on the drive train, this seems pretty good.

Getting that pan out with the old atf sloshing in it called for sliding it back down to under the front, and then used my scroungy old bilge-cleaning turkey baster to remove the oil, bit by bit. And then I could bend the pan and remove it from under the engine front and also put it into the plastic bag with the many used paper towels.

Boring stuff to most of you, who solved little mysteries like this years ago.... but perhaps there's a newer owner on the site that might find this trivia helpful.

And for all those with an alternative method, feel free to chime in!

The attached scan is the invoice with part # and the extra "washer" laid on it for 'show n tell' .