Puget sailor

Member II

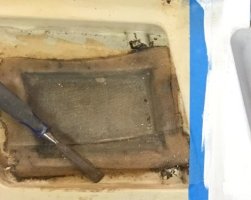

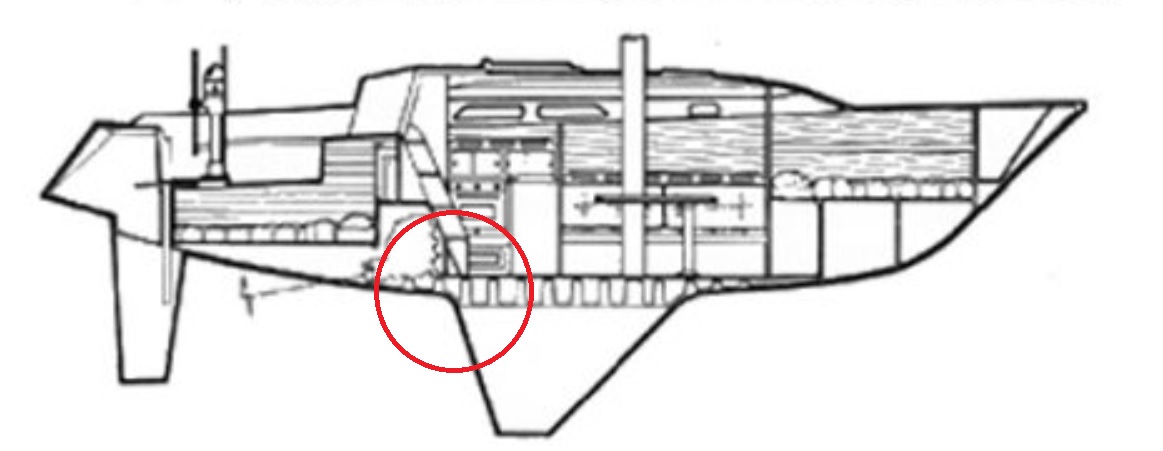

Looking at these pictures more clearly on my desktop, and considering the keel looks reasonable and the owners were clueless (let's for the moment give them the benefit of the doubt) I think we are seeing ice damage. Imagine a small leak from above, boat on the hard all winter, nobody aboard. Water level is up to the top of the tafg, including under the tafg "beams". Then it freezes solid as a rock because its in Maine. You have a several inch deep area of water freezing and expanding by a decent amount, pushing the tafg apart from the hull. The tafg is very robust indeed (thank you Ericson) and the hull is no slouch either. But the tabbed in connection and bonding to the hull is almost certainly the weak link and bam, it pops loose. Between ice, pushing it up, and subsequent force from sailing and hauling twice a year, there ya go. If the hull is sound, the, repair requires lots of cleaning (not easy), repositioning the tafg (moderate work) and rebonding (moderate work). And then it all needs to get put together nice and pretty again.

If this has happened once due to ice, it's happened many times in the northeast. If the price can be negotiated down enough to reflect the time and materials and then some, I'd ask around a other yards that do storage and repairs to see if they've seen similar damage from ice expansion. I bet they have. I'd think a responsible yard would check boats periodically during the winter for water unless they have a drain plug (some do, Ericson's don't seem to), but some owners have boats hauled to their own property too. I have a relative with a Tartan 34 that lives in his yard all winter, and he lives an hour from the coast outside Boston. It's cheaper that way. So oversight will vary, and damage is not hard in that situation.

Could also be a keel strike or drop or some combination of unfortunate events. How does the rest of the boat look? One thing is for sure, this is not normal wear and tear, so proceed accordingly. But if the hull is sound, and the keel connection sound, it does seem possible to repair. Perhaps no worse than a bad keel strike at 7 knots, although that can be bad too. This thread has some good insights, description of keel strike damage, and notes on tafg:

ericsonyachts.org

ericsonyachts.org

If this has happened once due to ice, it's happened many times in the northeast. If the price can be negotiated down enough to reflect the time and materials and then some, I'd ask around a other yards that do storage and repairs to see if they've seen similar damage from ice expansion. I bet they have. I'd think a responsible yard would check boats periodically during the winter for water unless they have a drain plug (some do, Ericson's don't seem to), but some owners have boats hauled to their own property too. I have a relative with a Tartan 34 that lives in his yard all winter, and he lives an hour from the coast outside Boston. It's cheaper that way. So oversight will vary, and damage is not hard in that situation.

Could also be a keel strike or drop or some combination of unfortunate events. How does the rest of the boat look? One thing is for sure, this is not normal wear and tear, so proceed accordingly. But if the hull is sound, and the keel connection sound, it does seem possible to repair. Perhaps no worse than a bad keel strike at 7 knots, although that can be bad too. This thread has some good insights, description of keel strike damage, and notes on tafg:

E32-200 - A fine line between stupid and clever

Here’s a rambling update in the writing-instead-of-financial-advice-or-psychological-therapy vein. I recently had a bit of a setback in my sailing adventures when I ran my boat into a big rock and damaged the keel and potentially other parts...