In an attempt to keep related Blogging narratives connected, here are Links to previous honeycomb work done on our boat:

ericsonyachts.org

ericsonyachts.org

ericsonyachts.org

ericsonyachts.org

The O-34, like many/most sailboats, has a number of lids/covers over internal storage spaces beneath settees, forepeak, and aft berth surfaces.

EY used 1//2” plywood with Formica laminate on both sides of all of these on the Olson’s. It was an efficient production scheme. They could run a router around the side and the center finger hole, after cutting each one out from a template, and in a couple of steps produce a finished attractive plate that would last the life of the boat.

The down side was weight. There are 13 of these “plates” throughout our boat interior for a total of 4024 square inches of surface. (!)

That’s a lot of unneeded extra weight in a design where lightness was valued enough to core every flat surface inside with balsa coring.

I started replacing these in groups many years ago, and completed the project this month.

It was never a really high priority since we are not out to wring the last micro-knot of speed out the boat what with all the cruising “stuff” we routinely carry.

It just seemed kind of cool, fits the personality of the design, and does make access to any of those compartments easier when there is less weight of cover to move aside.

(Aside: a separate project was replacing the truly heavy and long - about six foot - shelf that was glassed to the hull under the portside cockpit seat hatch. That was about 5/8” thick and really heavy. I cut it out and replaced it with a piece of honeycomb composite a number of years ago. Since all the 0-34’s are a bit overweight on the port side, there was ample justification for that particular bit of weight reduction.)

Back to the Story.

Forepeak-- there are three access pieces on the berth top plus one large slider piece that extends to be the “fill piece” for completing the forepeak berth.

Main cabin-- three pieces on the settee tops, two quite large, one smaller one, and one that replaced a plywood seat base for sitting at the nav desk.

Aft Cabin-- Three access plates.

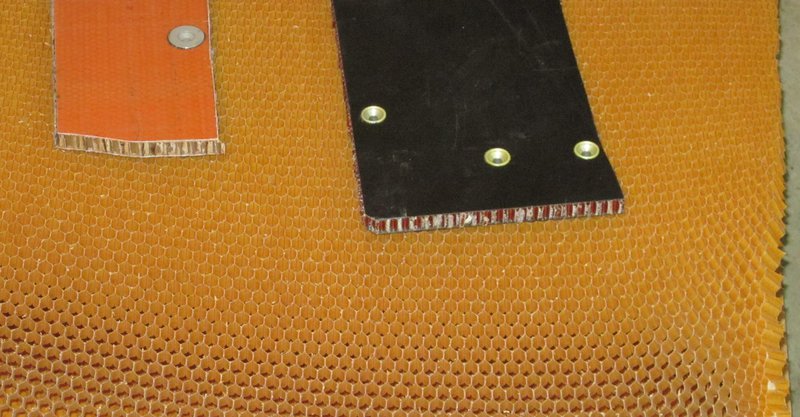

The replacements are all cut from skinned (“Hexel”) honeycomb that I bought years ago from the former Boeing Surplus store near Seattle. Unreal Bargain from a magical place to shop for DIY folk.

Back when a new sheet of skinned honeycomb was retailing for about $100, Boeing was selling off odd pieces of honeycomb scrap, in bins, for $.050/pound. (!) Most pieces had precision holes for special fastenings, and I would fill those with light poly filler. I knew sailors building out fast boats putting lots of this stuff to use for lightweight interior bits. Aircraft homebuilders were snapping them up, too.

When you lift up a cushion for a look, the appearance/color is a close match to the gel coat of the factory moldings. Not much to remark on if you don’t know the back story.

Since the raw edges of honeycomb are kind of utilitarian and sharp when handled, I route out between the skins about 3/16”, and fill in with poly putty - often “Bondo”.

On to the ‘numbers’….

The results of all this are not really astounding, but do prove that small increments multiplied over a large area are note worthy.

By weighing several pieces of the OEM plywood and then the Honeycomb finished panels with a precision scale, the weight reduction averages 36%. So a large panel, like the 16X48 sq. in. one over the starboard settee water tank used to weight approximately 120 oz or about 7.5#. Now it’s about 4.8#.

(There is a noticeable difference of effort when handling the new replacement parts; most noticeable with the larger ones.)

The reduction in weight for all of the panels that used to total approx. 39 pounds, would now be reduced to 25 pounds. The square inches are not precise, tho, due to panel corner rounding and finger holes in the centers.

All this might make the boat sail a nano-knot faster, however. Maybe. Perhaps.

Some projects are just soul satisfying even if slightly incomprehensible to normal people!

Actually, I likely removed a lot more weight than this when I replaced the factory framed-in aft 23 gallon water tank cover & sides. They used 5/8 ply w/formica laminated top and sides for that, also. Now it's all honeycomb. I did not separately weight all those pieces when cutting them out, but they were rather heavy.

Sidebar:

This is the same honeycomb that Boeing has used for decades for all the interior furniture parts inside their 7X7 passenger jets to save weight. And that floor you walk on inside the plane: inch-thick aluminum honeycomb panels! I used to marvel at the raw strength of that particular product at the Surplus Store. I have a few of the honeycomb panels left - some with carbon fiber skins, too. I used these panels to insulate our hull ceilings when replacing quite a bit of the old heavy duty fabric. Makes the interior more comfortable in hot or cool weather.

So here it is. Another long term project that has kept me off the streets and out of the bars. Alas, I will never reach the awesome project standard set by #bgary.

https://ericsonyachts.org/ie/ubs/dorkiest-boat-project-ever.645/

First, we’d have to get a Lab or a Golden…….

O34 - Hull Ceiling Replacement

This is an on-going upgrade project and is likely of less interest to Ericson owners with their nice teak ceilings. But there are a few Olson owners checking here from time to time. The Olson's have a heavy duty fabric glued to the hull sides...

O34 - Hull Ceiling Replacement, Finish Pix

Here are some pictures of the project as it moved further along. The next phase will be the upper parts. Color Matching Note: Some years ago when I replaced the factory counter top as part of refurbishing the galley sink, I found that a really...

The O-34, like many/most sailboats, has a number of lids/covers over internal storage spaces beneath settees, forepeak, and aft berth surfaces.

EY used 1//2” plywood with Formica laminate on both sides of all of these on the Olson’s. It was an efficient production scheme. They could run a router around the side and the center finger hole, after cutting each one out from a template, and in a couple of steps produce a finished attractive plate that would last the life of the boat.

The down side was weight. There are 13 of these “plates” throughout our boat interior for a total of 4024 square inches of surface. (!)

That’s a lot of unneeded extra weight in a design where lightness was valued enough to core every flat surface inside with balsa coring.

I started replacing these in groups many years ago, and completed the project this month.

It was never a really high priority since we are not out to wring the last micro-knot of speed out the boat what with all the cruising “stuff” we routinely carry.

It just seemed kind of cool, fits the personality of the design, and does make access to any of those compartments easier when there is less weight of cover to move aside.

(Aside: a separate project was replacing the truly heavy and long - about six foot - shelf that was glassed to the hull under the portside cockpit seat hatch. That was about 5/8” thick and really heavy. I cut it out and replaced it with a piece of honeycomb composite a number of years ago. Since all the 0-34’s are a bit overweight on the port side, there was ample justification for that particular bit of weight reduction.)

Back to the Story.

Forepeak-- there are three access pieces on the berth top plus one large slider piece that extends to be the “fill piece” for completing the forepeak berth.

Main cabin-- three pieces on the settee tops, two quite large, one smaller one, and one that replaced a plywood seat base for sitting at the nav desk.

Aft Cabin-- Three access plates.

The replacements are all cut from skinned (“Hexel”) honeycomb that I bought years ago from the former Boeing Surplus store near Seattle. Unreal Bargain from a magical place to shop for DIY folk.

Back when a new sheet of skinned honeycomb was retailing for about $100, Boeing was selling off odd pieces of honeycomb scrap, in bins, for $.050/pound. (!) Most pieces had precision holes for special fastenings, and I would fill those with light poly filler. I knew sailors building out fast boats putting lots of this stuff to use for lightweight interior bits. Aircraft homebuilders were snapping them up, too.

When you lift up a cushion for a look, the appearance/color is a close match to the gel coat of the factory moldings. Not much to remark on if you don’t know the back story.

Since the raw edges of honeycomb are kind of utilitarian and sharp when handled, I route out between the skins about 3/16”, and fill in with poly putty - often “Bondo”.

On to the ‘numbers’….

The results of all this are not really astounding, but do prove that small increments multiplied over a large area are note worthy.

By weighing several pieces of the OEM plywood and then the Honeycomb finished panels with a precision scale, the weight reduction averages 36%. So a large panel, like the 16X48 sq. in. one over the starboard settee water tank used to weight approximately 120 oz or about 7.5#. Now it’s about 4.8#.

(There is a noticeable difference of effort when handling the new replacement parts; most noticeable with the larger ones.)

The reduction in weight for all of the panels that used to total approx. 39 pounds, would now be reduced to 25 pounds. The square inches are not precise, tho, due to panel corner rounding and finger holes in the centers.

All this might make the boat sail a nano-knot faster, however. Maybe. Perhaps.

Some projects are just soul satisfying even if slightly incomprehensible to normal people!

Actually, I likely removed a lot more weight than this when I replaced the factory framed-in aft 23 gallon water tank cover & sides. They used 5/8 ply w/formica laminated top and sides for that, also. Now it's all honeycomb. I did not separately weight all those pieces when cutting them out, but they were rather heavy.

Sidebar:

This is the same honeycomb that Boeing has used for decades for all the interior furniture parts inside their 7X7 passenger jets to save weight. And that floor you walk on inside the plane: inch-thick aluminum honeycomb panels! I used to marvel at the raw strength of that particular product at the Surplus Store. I have a few of the honeycomb panels left - some with carbon fiber skins, too. I used these panels to insulate our hull ceilings when replacing quite a bit of the old heavy duty fabric. Makes the interior more comfortable in hot or cool weather.

So here it is. Another long term project that has kept me off the streets and out of the bars. Alas, I will never reach the awesome project standard set by #bgary.

https://ericsonyachts.org/ie/ubs/dorkiest-boat-project-ever.645/

First, we’d have to get a Lab or a Golden…….

- Published Date

- Mar 13, 2025