-

Untitled Document The 2024-2025 Fund Raising Season has Opened!

EricsonYachts.org has opened the season for raising funds to support the expenses of the site. If you would like to participate, please see the link below for additional information.

Thanks so much for your continued support of EricsonYachts.org!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Revival of Ericson Nonskid Decks [Master Thread]

- Thread starter JPS27

- Start date

716Ericson27

Lake Erie Viking

Nonskid

I gave it a good scrubbing with Simple Green cleaner. The Simple Green will remove any wax as well so plan on re-waxing the gelcoat on the topsides after application of the kiwigrip. Yes, I just went right over the original nonskid.

How did you prep for that? Did you just put it directly over the original "grid" non-skid?

I gave it a good scrubbing with Simple Green cleaner. The Simple Green will remove any wax as well so plan on re-waxing the gelcoat on the topsides after application of the kiwigrip. Yes, I just went right over the original nonskid.

716Ericson27

Lake Erie Viking

Nonskid

You do bring up a good point with the cleaning. While not impossible to keep clean, the texture of the kiwigrip does a good job of collecting dirt. I went with white to help keep the deck cool in the sun. However a darker color could help conceal the dirt buildup.

Hi Chris,

The Kiwigrip looks good. Do you find it easy to keep clean? What color was your original non-skid?

You do bring up a good point with the cleaning. While not impossible to keep clean, the texture of the kiwigrip does a good job of collecting dirt. I went with white to help keep the deck cool in the sun. However a darker color could help conceal the dirt buildup.

Totalthread

Alcodiesel,My nonskid has worn out in places (see pic) and I am considering reviving it with Totalboat Totalthread.

Seems like the best trade-off between effort and results. Well, doing nothing is also a top contender

Could you provide more details on your application technique and end results?

Thanks.

Alcodiesel,My nonskid has worn out in places (see pic) and I am considering reviving it with Totalboat Totalthread.

Seems like the best trade-off between effort and results. Well, doing nothing is also a top contender

Could you provide more details on your application technique and end results?

- How did you prep the surface? Did you grind off original non-skid or applied over? If over, did you just clean it with soap/solvent or lightly sanded as well?

- Did you color-match it? Manufacturer advises against "paint shop" type tints but folks apparently had success with some sort of "industrial" tint.

- How well does it hold up to wear?

- Did their proprietary anti-skid additive stay uniform or end up in the nonskid valleys just like sand would?

- Does it clean up well? Some (all?) nonskid paints trap dirt and are impossible to clean up.

- Could you post a few closeup pictures?

Thanks.

alcodiesel

Bill McLean

Sharanov:

I rolled it on with a 3" small foam roller. about the same difficulty or ease as paint. 2 coats. Very even distribution and finish of gritty material. Very good grip dry or wet.

- How did you prep the surface? Did you grind off original non-skid or applied over? If over, did you just clean it with soap/solvent or lightly sanded as well? I Just cleaned it with soap and water.

- Did you color-match it? Manufacturer advises against "paint shop" type tints but folks apparently had success with some sort of "industrial" tint. I left it white. The rest of the cockpit is slightly off white.

- How well does it hold up to wear? It's only been on a few months, but I sail a lot. Wear= 8.5/10

- Did their proprietary anti-skid additive stay uniform or end up in the nonskid valleys just like sand would? Uniform.

- Does it clean up well? Some (all?) nonskid paints trap dirt and are impossible to clean up. Yes, compared to sand. It seems there are no jagged edges to the surface and it cleans easily and well.

- Could you post a few closeup pictures? No pics but it looks just like the one in Chris's pic.\

I rolled it on with a 3" small foam roller. about the same difficulty or ease as paint. 2 coats. Very even distribution and finish of gritty material. Very good grip dry or wet.

Non Skid

Just my 2 cents.Every spring before I launch the boat, I wash and wax it from the top down and touch up or repaint the bottom as needed. When I start on top, I use a "Star Bright" product on the deck. It is supposedly not a wax and is recommended for non-skid surfaces and all of the deck. It has " PETF" (not sure about the order), which also protects it all frm the sun.

Like others, I have found that all shoes' & sneakers' soles harden in time. So, I always keep one hand on something solid other that a line as I move around the boat (actually, I do that anyway). I have to say the non-skid deck shown above looks good. I wouldn't strip it or touch it otherwise.

I am going to try the alcohol trick on the soles, I read earlier here.

starduff

Polonius

E-28

I

Just my 2 cents.Every spring before I launch the boat, I wash and wax it from the top down and touch up or repaint the bottom as needed. When I start on top, I use a "Star Bright" product on the deck. It is supposedly not a wax and is recommended for non-skid surfaces and all of the deck. It has " PETF" (not sure about the order), which also protects it all frm the sun.

Like others, I have found that all shoes' & sneakers' soles harden in time. So, I always keep one hand on something solid other that a line as I move around the boat (actually, I do that anyway). I have to say the non-skid deck shown above looks good. I wouldn't strip it or touch it otherwise.

I am going to try the alcohol trick on the soles, I read earlier here.

starduff

Polonius

E-28

I

tenders

Innocent Bystander

My nonskid had been primed and painted with Interlux Brightside and, maybe, once before I bought the boat in '91, with something else. The results were good but the paint builds up in the valleys between the nonskid grid, and over time the peaks of the grid wear down a bit. As a result the depth of the nonskid starts to be reduced. This may or may not affect traction when dry, but it almost certainly reduces the speed that rain or splashed water gets off the surface.

Once I start cutting into the deck for core repair, the jig is up for the nonskid.

There is nothing magic holding this old paint onto the deck. So to give new KiwiGrip a relatively uniform surface and the best chance of long-term adhesion, before I tape off and apply it, I take the old nonskid down with a 40 grit disc on a grinder until I can't detect the pattern with my fingers. This is exceedingly easy, quick, nonprecision work, but it does throw a lot of dust, so I recommend wrapping not one but TWO brightly-colored bandannas around the mouth and nose while doing it.

This treatment often also reveals a surprising number of former deck holes from long-abandoned hardware that had been inadequately filled. Better to remedy these situations now rather than deal with the aftermath!

Once I start cutting into the deck for core repair, the jig is up for the nonskid.

There is nothing magic holding this old paint onto the deck. So to give new KiwiGrip a relatively uniform surface and the best chance of long-term adhesion, before I tape off and apply it, I take the old nonskid down with a 40 grit disc on a grinder until I can't detect the pattern with my fingers. This is exceedingly easy, quick, nonprecision work, but it does throw a lot of dust, so I recommend wrapping not one but TWO brightly-colored bandannas around the mouth and nose while doing it.

This treatment often also reveals a surprising number of former deck holes from long-abandoned hardware that had been inadequately filled. Better to remedy these situations now rather than deal with the aftermath!

Last edited:

kapnkd

kapnkd

Hi Kapnkd,

I would also like to see some closeup photos especially the edges of the material. How is the adhesive holding up? Looks really good and I can imagine it is comfortable and grippy.

I will take some close up photos for you when back up North in February. Meanwhile you can also google eva teak or search for it on eBay as well.

This is is our first season with it so I’m as anxious as you to see how it holds up. It is soft to the touch, has excellent grip ability and supposed to last from 5 to 7 years.

Gico Flexmold

after some back and forth with Gibco (they had the wrong pattern registered for the Ericsons), we determined that GFS115 was the matching pattern. This stuff is NOT cheap (kinda $60/SF ... U.S...!) but with a certain level of skill and patience and two people, would render a good fix for smaller repair areas. Larger areas would take significantly more time, patience and skill

There are how-to videos on the site. Sorry can't seem to fix the upside-downishness of the pic.

after some back and forth with Gibco (they had the wrong pattern registered for the Ericsons), we determined that GFS115 was the matching pattern. This stuff is NOT cheap (kinda $60/SF ... U.S...!) but with a certain level of skill and patience and two people, would render a good fix for smaller repair areas. Larger areas would take significantly more time, patience and skill

There are how-to videos on the site. Sorry can't seem to fix the upside-downishness of the pic.

thanks Loren. I tried to rotate in my library but it seems to always want to 'send' in its original orientation no matter what I do to it : /

Yes I have considered that option... spray the non-skid with a release agent and lay something up to create a female pattern... but although expensive, the Gibco option seems SO much easier if I do go that way. I much prefer the original non-skid pattern vs removing all and going with KiwiGrip... just not sure how practical it will be in real life. I need to finish my decks first to assess. Maybe even do some sailing!

From talking to (very helpful) Customer Service at Gibco, it seems they have an extensive collection of patterns so could easily have the Olson pattern. It is cheaper in full 4X7 sheets but that is a huge investment.

Yes I have considered that option... spray the non-skid with a release agent and lay something up to create a female pattern... but although expensive, the Gibco option seems SO much easier if I do go that way. I much prefer the original non-skid pattern vs removing all and going with KiwiGrip... just not sure how practical it will be in real life. I need to finish my decks first to assess. Maybe even do some sailing!

From talking to (very helpful) Customer Service at Gibco, it seems they have an extensive collection of patterns so could easily have the Olson pattern. It is cheaper in full 4X7 sheets but that is a huge investment.

update on nonskid

Since I started this thread over two years ago I thought I'd give an update on my nonskid status and decisions. I did everything I could over that time to keep my nonskid as "sticky" as possible in it's original state. But it was never good regardless of how I cleaned it or what shoes I wore. I practiced with quart cans of kiwi grip and Total Boat products in the garage over the last few months as time permitted. In the end I went with total boat Total Tread paint (kingston grey). The kiwi grip was too much a departure in "look" for me. I only did the cockpit for now and will complete the rest when it's not so hot and humid. Here are some pictures. I'm very happy with the look. The grey is darker than I would have liked but I decided to just get the job started rather than agonize about what ifs. Of course, durability is still a question. I just finished this stage this past weekend. I have only gently walked on it so far, but traction is much better and I like how you can still see the original pattern.

Jay

Since I started this thread over two years ago I thought I'd give an update on my nonskid status and decisions. I did everything I could over that time to keep my nonskid as "sticky" as possible in it's original state. But it was never good regardless of how I cleaned it or what shoes I wore. I practiced with quart cans of kiwi grip and Total Boat products in the garage over the last few months as time permitted. In the end I went with total boat Total Tread paint (kingston grey). The kiwi grip was too much a departure in "look" for me. I only did the cockpit for now and will complete the rest when it's not so hot and humid. Here are some pictures. I'm very happy with the look. The grey is darker than I would have liked but I decided to just get the job started rather than agonize about what ifs. Of course, durability is still a question. I just finished this stage this past weekend. I have only gently walked on it so far, but traction is much better and I like how you can still see the original pattern.

Jay

Great look! I think this is the route I will take when the time comes. As to wear, I would guess that the "middle" sections of each painted area (where everyone steps) are the sections that will wear the paint the fastest. The good news would be that the edges (the hardest part to mask and paint) will probably hold up quite well. Maybe it would be possible to touch up the middle sections every few years without repainting the entire area.

Did you experiment with or find ways to prevent the paint from filling up the lowered "troughs" between the raised non-skid "squares?"

My tan non-skid is just starting to show what I thought was gray-ish "staining." I couldn't figure out where the "stain" was coming from. Now I'm starting to think it's just the beige gelcoat wearing thin and starting to show the grayish FRP below it.

Did you experiment with or find ways to prevent the paint from filling up the lowered "troughs" between the raised non-skid "squares?"

My tan non-skid is just starting to show what I thought was gray-ish "staining." I couldn't figure out where the "stain" was coming from. Now I'm starting to think it's just the beige gelcoat wearing thin and starting to show the grayish FRP below it.

I was trying to mentally make note of "things I learned" as I went along. I'll try to capture them here. It was pretty straightforward. It was a job I put off due to my imagination of things that could go wrong. There were very few in actuality. I used regular blue painters tape, one inch wide. There were few long straight lines to tape. Even the "straight lines had some curve. I passed on trying to razor cut the rounded corners and instead used the approach of tearing about 1 inch lengths of tape and curving around lines. I think that made the result much better. I also made sure I saw a smidge of white gelcoat to ensure that I covered all the yellow.

I used a 4 in foam roller like the kinds used for epoxy. They worked fine. I made sure the roller was loaded before my first roll and I did one coat rolling vertically they horizontally. In places you could see faint hints of beige gelcoat but I tried to take the varnishing approach of not "worrying" and overbrushing. The next coat of paint covered those spots just fine. Two coats was a must IMO. 3 might be overkill. I figure I'll use leftover paint for touch ups, but I'm also expecting it to fade. So who knows. I didn't do anything special to avoid pooling etc. It just flowed nicely. I did make sure I worked in the morning and before temps got above 80 (with no rain in sight for a couple of days).

Other thoughts:

I removed tape about 8 hours after the second coat was applied. This required yoga moves since I didn't yet want to step on the painted sections, but didn't want to pull up paint later.

I unscrewed the lazarette hinges to make the taping and painting more precise in those spots.

I had lots of latex gloves and changed them liberally to keep paint from findings its way to unwanted areas. I had plenty of acetone and clean rags and paper towels. I was not as environmentally conscious I would have liked to be in that regard.

pre-cleaning: I scrubbed with Dawn and some TSP, then I scrubbed with simple green contractor grade solution (it's purple, go figure). I did the scrubbing the day before. Then I wiped down with acetone on the day of.

I used a green scotch bright pad in between the coats and used my shop vac to suck up the dust. Jamestown site suggests 220 grit paper, but I went with the pads.

Oh and yes, KennethK, I had dark areas that you speak of are where it has worn through if your nonskid i like mine.

I used a 4 in foam roller like the kinds used for epoxy. They worked fine. I made sure the roller was loaded before my first roll and I did one coat rolling vertically they horizontally. In places you could see faint hints of beige gelcoat but I tried to take the varnishing approach of not "worrying" and overbrushing. The next coat of paint covered those spots just fine. Two coats was a must IMO. 3 might be overkill. I figure I'll use leftover paint for touch ups, but I'm also expecting it to fade. So who knows. I didn't do anything special to avoid pooling etc. It just flowed nicely. I did make sure I worked in the morning and before temps got above 80 (with no rain in sight for a couple of days).

Other thoughts:

I removed tape about 8 hours after the second coat was applied. This required yoga moves since I didn't yet want to step on the painted sections, but didn't want to pull up paint later.

I unscrewed the lazarette hinges to make the taping and painting more precise in those spots.

I had lots of latex gloves and changed them liberally to keep paint from findings its way to unwanted areas. I had plenty of acetone and clean rags and paper towels. I was not as environmentally conscious I would have liked to be in that regard.

pre-cleaning: I scrubbed with Dawn and some TSP, then I scrubbed with simple green contractor grade solution (it's purple, go figure). I did the scrubbing the day before. Then I wiped down with acetone on the day of.

I used a green scotch bright pad in between the coats and used my shop vac to suck up the dust. Jamestown site suggests 220 grit paper, but I went with the pads.

Oh and yes, KennethK, I had dark areas that you speak of are where it has worn through if your nonskid i like mine.

Last edited:

Alan Gomes

Sustaining Partner

That looks really, really nice! Assuming the colors in the photos (as displayed on my monitor) is close to reality, I think the color you chose is perfect.

frick

Sustaining Member

A Cheap and renewable fix

I had a friend who deck became very slippery.

The quick fix was he did a deep clean and then applied a surfboard Wax on the anti skid.

It worked and also kept his deck clean for the season.

If I remember he used Dave's Deck Wax, but most all surfboard wax is non skid.

Rick

also

http://www.starbrite.com/item/non-skid-deck-wax

I had a friend who deck became very slippery.

The quick fix was he did a deep clean and then applied a surfboard Wax on the anti skid.

It worked and also kept his deck clean for the season.

If I remember he used Dave's Deck Wax, but most all surfboard wax is non skid.

Rick

also

http://www.starbrite.com/item/non-skid-deck-wax

Last edited:

Prairie Schooner

Jeff & Donna, E35-3 purchased 7/21

Non-Skid Restoration

Bridge deck, Kismet, 1986 E35-3

After 38 years our non-skid is becoming slick enough to be a danger in some conditions. It's especially noticeable on the cockpit areas. A recent trip to the 2024 Newport (RI) Boat Show gave me an opportunity to ask questions of vendors.

There isn't a master thread dedicated to Non-Skid but this seems the most likely place to extend the discussion as it touches on all the options and goes into how-to a bit. There is a master thread on deck-painting-in-general which includes a fair amount on non-skid, but you need to wade through a lot of posts on shiny paint. Below are links mostly from the EYo site. Older posts exist here but I stopped searching at 2011.

Other Non-Skid-specific Threads

ericsonyachts.org

ericsonyachts.org

ericsonyachts.org

2003, updated 2019 https://www.practical-sailor.com/boat-maintenance/paints/restoring-decks-nonskid-options

ericsonyachts.org

2003, updated 2019 https://www.practical-sailor.com/boat-maintenance/paints/restoring-decks-nonskid-options

All Deck Paint concerns, including significant comment on Non-Skid

ericsonyachts.org

ericsonyachts.org

ericsonyachts.org

https://ericsonyachts.org/ie/threads/paint-selections.10801/ + 2 for Kiwi Grip

ericsonyachts.org

https://ericsonyachts.org/ie/threads/paint-selections.10801/ + 2 for Kiwi Grip

ericsonyachts.org

post # 56, like Kiwi grip? > https://durabakdepot.com/durabak18.php

ericsonyachts.org

post # 56, like Kiwi grip? > https://durabakdepot.com/durabak18.php

Mostly about re-core, but a few posts about non-skid

ericsonyachts.org

ericsonyachts.org

ericsonyachts.org

ericsonyachts.org

I've been trying to make sense of all the options and it seems like there are some general categories.

‘Paint’ and Grit (in-can or sprinkled)

Roller Applied Texture

Texture by Appliqué or Mold sheet

Alternative

Bridge deck, Kismet, 1986 E35-3

After 38 years our non-skid is becoming slick enough to be a danger in some conditions. It's especially noticeable on the cockpit areas. A recent trip to the 2024 Newport (RI) Boat Show gave me an opportunity to ask questions of vendors.

There isn't a master thread dedicated to Non-Skid but this seems the most likely place to extend the discussion as it touches on all the options and goes into how-to a bit. There is a master thread on deck-painting-in-general which includes a fair amount on non-skid, but you need to wade through a lot of posts on shiny paint. Below are links mostly from the EYo site. Older posts exist here but I stopped searching at 2011.

Other Non-Skid-specific Threads

Deck Nonskid Matching

When this boat was built a water-tank fill hole was drilled in the wrong location. No doubt this occurred at 4:56 pm on a Friday. The mistake was repaired with what looks like epoxy--after the nonskid treatment ("paint") was applied. I believe the whitish feathering is epoxy. So--how to...

Non-skid rejuvenating

My non-skid on deck doesn’t grip as well as I’d like to . I’ve been told it could be wax on the non-skid, but the guy who waxed my boat tells me he doesn’t use wax on the non-skid . Maybe it’s just worn (?) . Is there anyway to rejuvenate the non-skid ( or at least improve it short of...

All Deck Paint concerns, including significant comment on Non-Skid

Painting Deck and Hull [Master Thread]

My new dock neighbor, Hank Toles*, is refinishing his decks with two-part paint. He had some minor gelcoat wear. As usual the effect is new-boat shiny, and a reminder that old boats can gleam again. *Update 2024: Hank Toles died a few years after the job was finished. The boat has...

Deck Paint

Need a little help. We recently purchased a 25 plus which we've been cleaning and restoring. There are a few sun faded areas on the upper deck that I maybe interested in repainting; these are within the molded nonslip areas. Much of this is in great shape and I don't want repaint the entire...

Need ideas on paint for my boat

So heres the deal. My E29is a 1972. I spent 6+ hours yesterday on my knees scrubbing and at best my topside still looks dingy : ( I've checked before into painting and get numbers back from $6k to $14k. I simply can't afford that with kids in college and private school. I'm beyond blessed...

Mostly about re-core, but a few posts about non-skid

Deck Repair, Injectadeck and Options [Master Thread]

If folks have noted my postings here Silver Maiden is getting lots of work done to her. Work that has been deferred due to either lack of time, or money. Well money is tight now with me being out of work due to Covid-19 shutdowns, but I do have time. One of the things that has to be fixed...

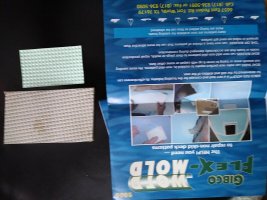

O34 - Deck & handrails, Casting Procedure(page 2) | Casting Hardware Fastener Holes

The shop is about to start on the final deck prep for painting. Quite a bit of work has gone into several other projects that were also planned for this re-fit. Not much to see yet, but considerable glass work has gone into prep for a furnace...

I've been trying to make sense of all the options and it seems like there are some general categories.

‘Paint’ and Grit (in-can or sprinkled)

Roller Applied Texture

Texture by Appliqué or Mold sheet

Alternative

Prairie Schooner

Jeff & Donna, E35-3 purchased 7/21

The threads in categories below often contain comments about other systems so my sorting may seem somewhat arbitrary.

- - - - -

‘Paint’ and Grit (in-can or sprinkled)

ericsonyachts.org

ericsonyachts.org

ericsonyachts.org

ericsonyachts.org

ericsonyachts.org

ericsonyachts.org

This is the system I've seen most when friends fix non-skid on older boats, and as original on a lot of boats. It has the advantage of being easier to repair or reproduce in entirety. And, if done well, it can be very effective technically. People note that some can be hard on bare skin. A wide variety of colors can be available, depending on the system. Some can be mixed or tinted. Some products have the grit already in a can. If sprinkling onto wet 'paint' it can be difficult to get a consistent pattern. I've seen hard grit listed, perhaps of some mineral, and sometimes more flexible polymer (a catch-all term) grit.

Totaltread 4 colors https://www.totalboat.com/products/totaltread-non-skid-deck-paint?_pos=1&_sid=49d79ac52&_ss=r

Gleitschutzfarbe 3 colors https://www.epifanes.com/page/nonskid

TuffCoat 15 colors https://pettitpaint.com/tuffcoat

Interdeck 4 (5?) colors https://www.interlux.com/en/us/boat-paint/topcoat-finish/interdeck

Alexseal Non-skid https://www.alexseal.com/products/auxiliary-products/additives-non-skid

Griptex additive https://www.awlgrip.com/north-america/products/additive/griptex#overview

If we go with this system, I'm leaning toward Totaltread. I want to examine a sample of it applied, but the polypropylene beads sound better than silica based grit. Also, it's pre-mixed.

- - - - -

Roller Applied Texture

ericsonyachts.org

+1 kiwi https://ericsonyachts.org/ie/threads/interlux-bilgekote.18723/

ericsonyachts.org

+1 kiwi https://ericsonyachts.org/ie/threads/interlux-bilgekote.18723/

https://ericsonyachts.org/ie/threads/original-e29-skid-grid-repair-painting-need-tips.11828/

ericsonyachts.org

ericsonyachts.org

ericsonyachts.org

post # 56, like Kiwi grip? > https://durabakdepot.com/durabak18.php

ericsonyachts.org

post # 56, like Kiwi grip? > https://durabakdepot.com/durabak18.php

At the boat show I spoke directly with the PYI rep. Kiwi Grip is water based. There is no grit. The texture comes from a very open pattern roller. It comes in 5 stock colors, but you can give them a Sherwin Williams (iirc) paint chip number and they will provide color matched product. This is a major plus for me. The texture's appearance is a major negative for me. It comes in plastic pouches with a pour spout. At the show there was a one liter pouch. The website says it's also available in 4L. You can create stronger texture by waiting for the paint to dry a little bit and rolling again. They had a test strip on the floor that was done with three different degrees of texture. After being stomped on by countless show attendees it still had good grip. People who post here have high praise for the effectiveness of Kiwi Grip.

I'm leaning against this system as it looks so different from original.

- - - - -

Texture by Appliqué or Mold sheet

https://ericsonyachts.org/ie/threads/how-to-match-the-ericson-non-skid-pattern.14402/

gibcoflexmold.com

2002 - 2004 https://www.westsystem.com/?s=non-skid

gibcoflexmold.com

2002 - 2004 https://www.westsystem.com/?s=non-skid

nitrile/pvc https://www.treadmaster.co.uk/

ericsonyachts.org

EVA foam, many mfrs, just one example: https://www.foceanboat.com/

ericsonyachts.org

EVA foam, many mfrs, just one example: https://www.foceanboat.com/

Gibco started out making negative pattern sheets for manufacturers to embed in their molds. The crispness of the mold patterning would degrade with subsequent laminations so molds were designed to have the texture panels replaced periodically. Initially Gibco started selling smaller panels of the negative (female) texture panels to consumers to do repairs.

For the negative (mold) panels you layer gelcoat onto the deck, the panel is placed over it, and it is weighted down until the resin cures. (there are more nuances, but that's the gist) A variation of this is described in several posts here where people made molds from a less damaged section of deck. That would not be my choice because even the most untrodden section will have suffered damage from UV and other elements. It wouldn't have the crispness of a newly machined pattern. But if I needed to do a small repair it's something I'd definitely try.

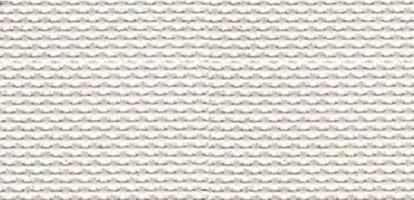

In what I gather is a more recent development, Gibco offer sheets of pre-cured gelcoat positive (male) texture that can be adhered directly to the deck, called Re-Deck. It is sold plain back or with a "proprietary" 3M double-stick applied. I handled the sheets at the show and they are fairly flexible. The photo above is of a sample they gave me. You'd need to sand down the old texture to a flat smooth surface. Some hardware would have to be removed for this process. For example, the cockpit sole would require removing the pedestal and guard. I suppose I could leave the hardware and do it in two pieces with a seam. Also, I think pattern 315 in their Flex-Mold roster is closest to our boat. That pattern doesn't seem to be available as Re-Deck. I've written the rep for more information.

I wouldn't use the diamond Treadmaster because it looks too industrial. They do make a smaller pattern which might be acceptable. It is available at Defender as Lewmar Treadmaster M-tec Ultra-Grip, shown above.

- https://www.treadmaster.co.uk/produ...os=3&_sid=fe1f440c2&_ss=r&variant=20642430279

I wouldn't use the EVA foam because the patterns I've seen depart too much from the original Ericson look. In addition, I don't think the foam would be rigid enough to resist peeling up sooner than later.

Real teak - If you win the lottery and want a very trad look, you could have actual teak decking made.

- https://teakdeckcompany.com/

- - - - -

Alternative

ericsonyachts.org

It seems like there are actually two categories here. One is actual wax and others are some sort of coating that is somewhat matte.

ericsonyachts.org

It seems like there are actually two categories here. One is actual wax and others are some sort of coating that is somewhat matte.

Waxing non-skid sounds like an oxymoron. I've never surfed, but guess the wax would need to be grippy. It sounds like it goes on pretty thick, though. And I worry if it doesn't work, the residue won't allow some other system to stick without sanding the original texture off completely. Also, as I think about it, what would it do to clothes if sitting on it on a hot day?

In post #17 Doug recaps the coatings discussed. Don, in post #14, likes Woody Wax. In post #18 Marlin throws a big red flag at it. It seems to me that for 40 y.o. non-skid, the sealers would be only a half measure at best.

- - - - - - - - - -

Something one of the gang mentions, it might have been Christian, is the importance of good looking non-skid for resale value. Of course its first job is to work, but an ugly non-skid surface would be a big turnoff for me as a potential buyer. To my taste, Ericson hit it just about perfect with the original configuration and color.

So this is the state of my research right now. The Gibco gelcoat sheets come closest to original but it's expensive, not a direct color match, and a lot of work. Ease of process and cost are major mitigating factors. At this point I think we'll probably end up with something like Totaltread, cleaning the existing pattern, but not sanding it off. Maybe I'll mix two colors or tint it to come closer to Ericson original. Whatever I do, I'll start with the cockpit sole and see how that goes. I plan to do this chore in the Spring, researching more in the meantime. The next step is getting samples and comparing pricing for likely candidates.

Please chip in with your thoughts and experience.

caveat: All this is "As I Currently Understand It". A sometimes leaky proposition.

Jeff

- - - - -

‘Paint’ and Grit (in-can or sprinkled)

Painting Deck and Hull [Master Thread]

My new dock neighbor, Hank Toles*, is refinishing his decks with two-part paint. He had some minor gelcoat wear. As usual the effect is new-boat shiny, and a reminder that old boats can gleam again. *Update 2024: Hank Toles died a few years after the job was finished. The boat has...

Rolling and Tipping cabin top with Awlgrip

I was inspired by one of Christian Williams’ posts about his neighbors boat that had the top deck rolled and tipped, as well as adding sand to the existing raised nonskid areas. This project took me about 2 weeks, and I still have a day or two left of touching up some areas where the gray seeped...

Non-skid painting came out well. Interlux interdek sand beige.

This is the system I've seen most when friends fix non-skid on older boats, and as original on a lot of boats. It has the advantage of being easier to repair or reproduce in entirety. And, if done well, it can be very effective technically. People note that some can be hard on bare skin. A wide variety of colors can be available, depending on the system. Some can be mixed or tinted. Some products have the grit already in a can. If sprinkling onto wet 'paint' it can be difficult to get a consistent pattern. I've seen hard grit listed, perhaps of some mineral, and sometimes more flexible polymer (a catch-all term) grit.

Totaltread 4 colors https://www.totalboat.com/products/totaltread-non-skid-deck-paint?_pos=1&_sid=49d79ac52&_ss=r

Gleitschutzfarbe 3 colors https://www.epifanes.com/page/nonskid

TuffCoat 15 colors https://pettitpaint.com/tuffcoat

Interdeck 4 (5?) colors https://www.interlux.com/en/us/boat-paint/topcoat-finish/interdeck

Alexseal Non-skid https://www.alexseal.com/products/auxiliary-products/additives-non-skid

Griptex additive https://www.awlgrip.com/north-america/products/additive/griptex#overview

If we go with this system, I'm leaning toward Totaltread. I want to examine a sample of it applied, but the polypropylene beads sound better than silica based grit. Also, it's pre-mixed.

- - - - -

Roller Applied Texture

Non Skid grid sanding

My E35-2 is in great need of some deck paint. My current concern is the nonskid grid pattern. Seems one of the previous owners painted the grid part with what looks like cool deck coating. its a faded looking peach color. I would like to know how to sand off that paint without sanding off the...

https://ericsonyachts.org/ie/threads/original-e29-skid-grid-repair-painting-need-tips.11828/

Non-skid deck

Has anyone had any experience with Kiwi Grip non-skid deck coating??? Interested in its durability...thanks Chris

Need ideas on paint for my boat

So heres the deal. My E29is a 1972. I spent 6+ hours yesterday on my knees scrubbing and at best my topside still looks dingy : ( I've checked before into painting and get numbers back from $6k to $14k. I simply can't afford that with kids in college and private school. I'm beyond blessed...

At the boat show I spoke directly with the PYI rep. Kiwi Grip is water based. There is no grit. The texture comes from a very open pattern roller. It comes in 5 stock colors, but you can give them a Sherwin Williams (iirc) paint chip number and they will provide color matched product. This is a major plus for me. The texture's appearance is a major negative for me. It comes in plastic pouches with a pour spout. At the show there was a one liter pouch. The website says it's also available in 4L. You can create stronger texture by waiting for the paint to dry a little bit and rolling again. They had a test strip on the floor that was done with three different degrees of texture. After being stomped on by countless show attendees it still had good grip. People who post here have high praise for the effectiveness of Kiwi Grip.

I'm leaning against this system as it looks so different from original.

- - - - -

Texture by Appliqué or Mold sheet

https://ericsonyachts.org/ie/threads/how-to-match-the-ericson-non-skid-pattern.14402/

How-To Videos | Gibco Flex-Mold, Non Skid Surfaces

nitrile/pvc https://www.treadmaster.co.uk/

Non-skid stickers as opposed to painting

Hello all, Is there someplace to order non-skid stickers for the topside of our 27' Ericson or am I stuck with painting option? Thanks in advance for your input! Regards, Chris

Gibco started out making negative pattern sheets for manufacturers to embed in their molds. The crispness of the mold patterning would degrade with subsequent laminations so molds were designed to have the texture panels replaced periodically. Initially Gibco started selling smaller panels of the negative (female) texture panels to consumers to do repairs.

For the negative (mold) panels you layer gelcoat onto the deck, the panel is placed over it, and it is weighted down until the resin cures. (there are more nuances, but that's the gist) A variation of this is described in several posts here where people made molds from a less damaged section of deck. That would not be my choice because even the most untrodden section will have suffered damage from UV and other elements. It wouldn't have the crispness of a newly machined pattern. But if I needed to do a small repair it's something I'd definitely try.

In what I gather is a more recent development, Gibco offer sheets of pre-cured gelcoat positive (male) texture that can be adhered directly to the deck, called Re-Deck. It is sold plain back or with a "proprietary" 3M double-stick applied. I handled the sheets at the show and they are fairly flexible. The photo above is of a sample they gave me. You'd need to sand down the old texture to a flat smooth surface. Some hardware would have to be removed for this process. For example, the cockpit sole would require removing the pedestal and guard. I suppose I could leave the hardware and do it in two pieces with a seam. Also, I think pattern 315 in their Flex-Mold roster is closest to our boat. That pattern doesn't seem to be available as Re-Deck. I've written the rep for more information.

I wouldn't use the diamond Treadmaster because it looks too industrial. They do make a smaller pattern which might be acceptable. It is available at Defender as Lewmar Treadmaster M-tec Ultra-Grip, shown above.

- https://www.treadmaster.co.uk/produ...os=3&_sid=fe1f440c2&_ss=r&variant=20642430279

I wouldn't use the EVA foam because the patterns I've seen depart too much from the original Ericson look. In addition, I don't think the foam would be rigid enough to resist peeling up sooner than later.

Real teak - If you win the lottery and want a very trad look, you could have actual teak decking made.

- https://teakdeckcompany.com/

- - - - -

Alternative

Wax on the deck?

Something in another thread sparked a random question.... do any of you wax your decks? If so, what product(s) do you use? My boat is a grungy mess every spring when it is time to scrub off months of wetness. Oftentimes it is a job for hands-and-knees with a bristle-brush to get the grunge...

Waxing non-skid sounds like an oxymoron. I've never surfed, but guess the wax would need to be grippy. It sounds like it goes on pretty thick, though. And I worry if it doesn't work, the residue won't allow some other system to stick without sanding the original texture off completely. Also, as I think about it, what would it do to clothes if sitting on it on a hot day?

In post #17 Doug recaps the coatings discussed. Don, in post #14, likes Woody Wax. In post #18 Marlin throws a big red flag at it. It seems to me that for 40 y.o. non-skid, the sealers would be only a half measure at best.

- - - - - - - - - -

Something one of the gang mentions, it might have been Christian, is the importance of good looking non-skid for resale value. Of course its first job is to work, but an ugly non-skid surface would be a big turnoff for me as a potential buyer. To my taste, Ericson hit it just about perfect with the original configuration and color.

So this is the state of my research right now. The Gibco gelcoat sheets come closest to original but it's expensive, not a direct color match, and a lot of work. Ease of process and cost are major mitigating factors. At this point I think we'll probably end up with something like Totaltread, cleaning the existing pattern, but not sanding it off. Maybe I'll mix two colors or tint it to come closer to Ericson original. Whatever I do, I'll start with the cockpit sole and see how that goes. I plan to do this chore in the Spring, researching more in the meantime. The next step is getting samples and comparing pricing for likely candidates.

Please chip in with your thoughts and experience.

caveat: All this is "As I Currently Understand It". A sometimes leaky proposition.

Jeff

Prairie Schooner

Jeff & Donna, E35-3 purchased 7/21

Hi Jay,I was trying to mentally make note of "things I learned" as I went along. I'll try to capture them here. It was pretty straightforward. It was a job I put off due to my imagination of things that could go wrong. There were very few in actuality. I used regular blue painters tape, one inch wide. There were few long straight lines to tape. Even the "straight lines had some curve. I passed on trying to razor cut the rounded corners and instead used the approach of tearing about 1 inch lengths of tape and curving around lines. I think that made the result much better. I also made sure I saw a smidge of white gelcoat to ensure that I covered all the yellow.

I used a 4 in foam roller like the kinds used for epoxy. They worked fine. I made sure the roller was loaded before my first roll and I did one coat rolling vertically they horizontally. In places you could see faint hints of beige gelcoat but I tried to take the varnishing approach of not "worrying" and overbrushing. The next coat of paint covered those spots just fine. Two coats was a must IMO. 3 might be overkill. I figure I'll use leftover paint for touch ups, but I'm also expecting it to fade. So who knows. I didn't do anything special to avoid pooling etc. It just flowed nicely. I did make sure I worked in the morning and before temps got above 80 (with no rain in sight for a couple of days).

Other thoughts:

I removed tape about 8 hours after the second coat was applied. This required yoga moves since I didn't yet want to step on the painted sections, but didn't want to pull up paint later.

I unscrewed the lazarette hinges to make the taping and painting more precise in those spots.

I had lots of latex gloves and changed them liberally to keep paint from findings its way to unwanted areas. I had plenty of acetone and clean rags and paper towels. I was not as environmentally conscious I would have liked to be in that regard.

pre-cleaning: I scrubbed with Dawn and some TSP, then I scrubbed with simple green contractor grade solution (it's purple, go figure). I did the scrubbing the day before. Then I wiped down with acetone on the day of.

I used a green scotch bright pad in between the coats and used my shop vac to suck up the dust. Jamestown site suggests 220 grit paper, but I went with the pads.

Oh and yes, KennethK, I had dark areas that you speak of are where it has worn through if your nonskid i like mine.

Your solution is what we may well end up with. How long did you have the boat after you applied the Totaltread? What are your thoughts about the choice after living with it for a while? Would you do anything different to prep the surface for Totaltread? Was that enough for the finish hold up to wear?

Thanks,

Jeff